Method for producing hose with protector layer

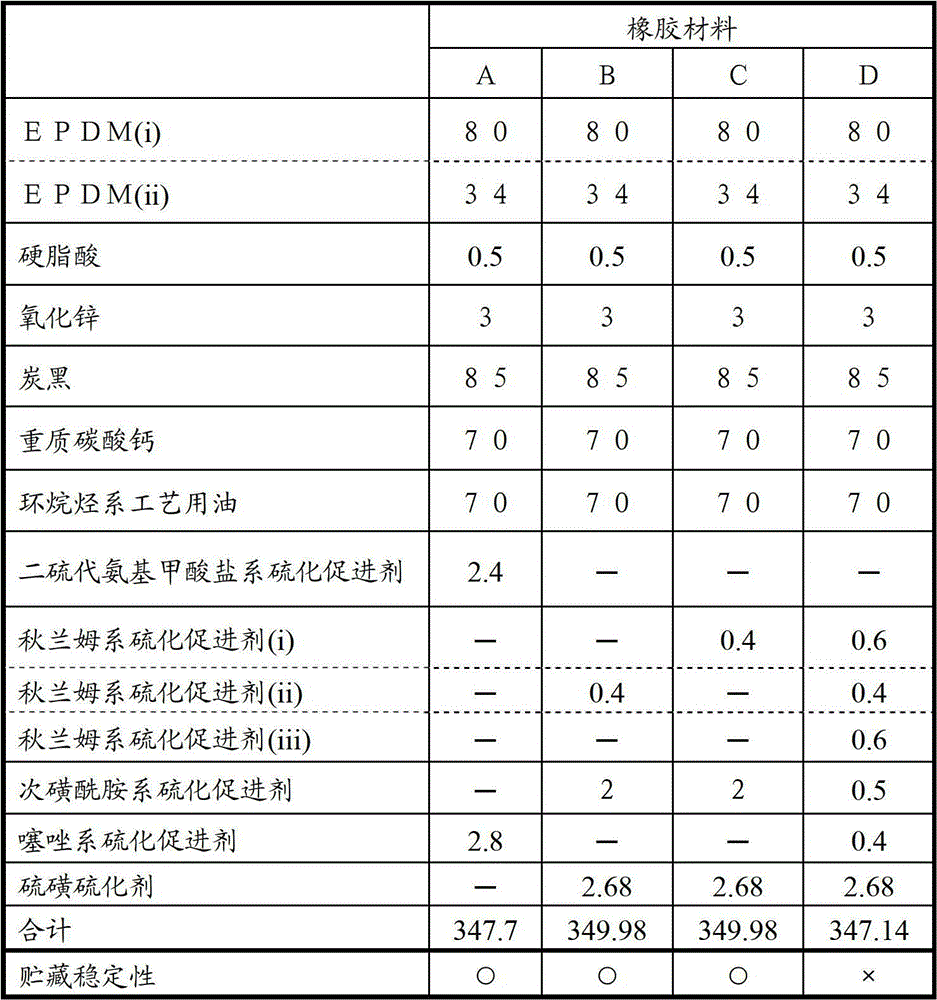

A technology with a protective layer and a protective layer, which is applied to hoses, pipes, coatings, etc., can solve the problems of easy scorching and poor storage stability, and achieve the effects of shortened manufacturing time, good dispersion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

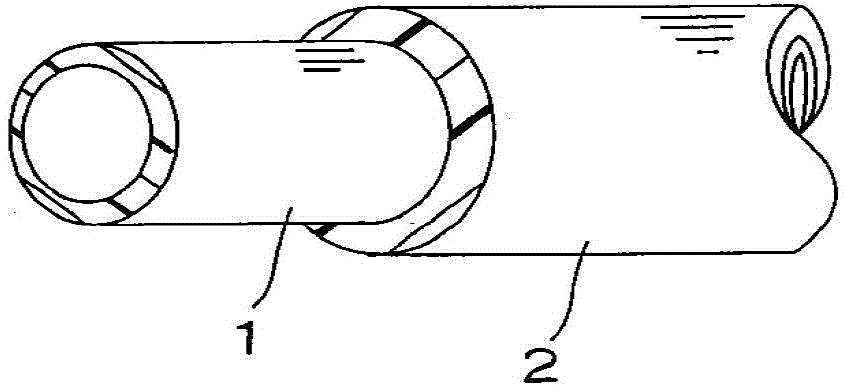

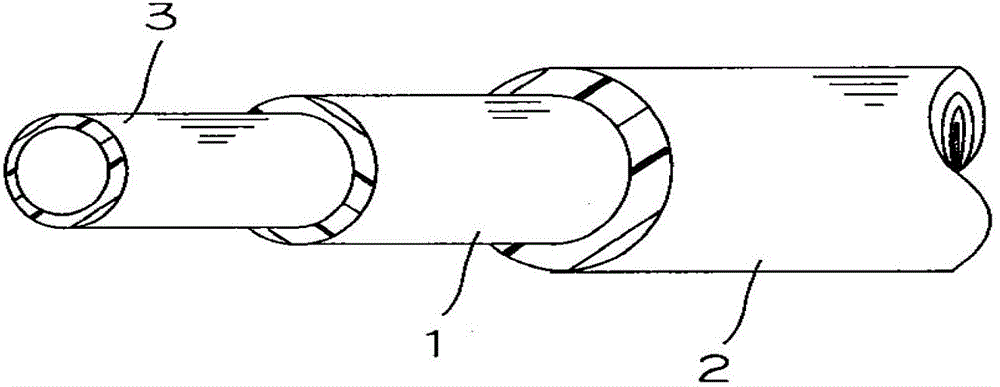

Image

Examples

Embodiment 1

[0114] Copolymer of ethylene, hexafluoropropylene, and tetrafluoroethylene (EFEP) (manufactured by DAIKIN INDUSTRIES, Ltd., NEOFLON RP5000) and polyamide 12 (PA12) (manufactured by ARKEMA CORPORATION, Rilsan AESN NOIR P20TL, melting point 170°C) pellets A resin hose having an inner layer (polyamide-based resin layer) on the outer peripheral surface of the innermost layer (fluororesin layer) was produced by coextrusion molding into a hose shape. Separately, the above-mentioned first rubber material and second rubber material were prepared and mixed in a screw mixer (manufactured by Mitsuha Seisakusho, 60G-12D-HB) to prepare a rubber composition for forming a protective layer. The temperature during mixing is adjusted at 80~105°C. Next, the rubber composition was continuously extruded on the outer periphery of the inner layer (polyamide-based resin layer) to produce an unvulcanized hose, which was continuously supplied to a hot air furnace, and the unvulcanized rubber was vulcan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com