Flue-cured tobacco cultivation method

A cultivation method and flue-cured tobacco technology, applied in horticultural methods, botanical equipment and methods, horticulture, etc., can solve the problems of inability to change the shape characteristics of upper leaves, increase the difficulty of loading tobacco, and reduce the income of tobacco farmers, so as to improve the quality of upper leaves, The effect of reducing the production of nicotine and reducing the content of nicotine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

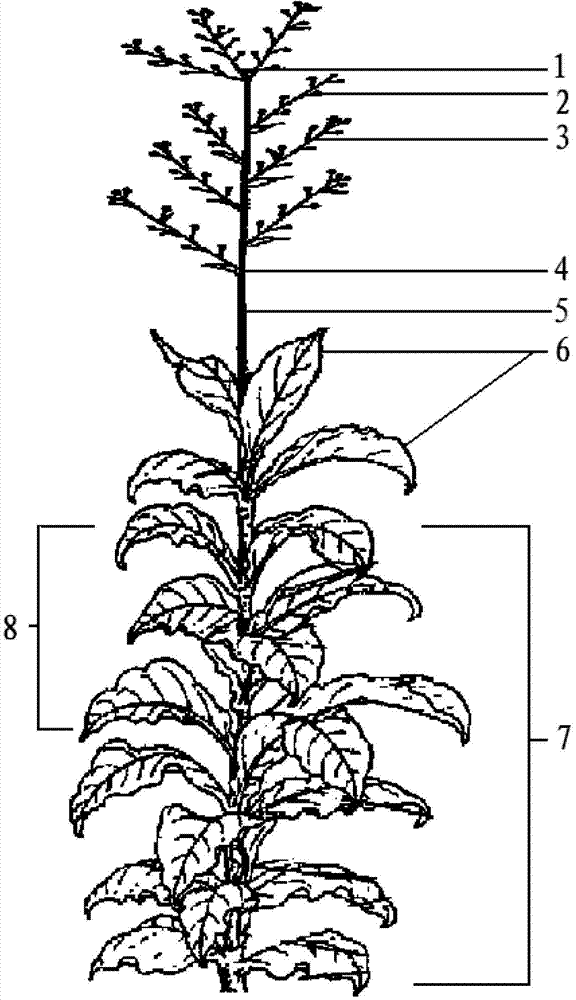

[0039] Embodiment 1 "Beating leaves and leaving flowers" cultivation technique

[0040] The experimental tobacco strains were selected from Guizhou production areas, and the experiment was repeated 3 times in 3 plots, with 20 plants in each plot. When the center flower is open, top the tobacco plant and keep 3 top flowers and 18 leaves.

[0041] Another 20 tobacco plants with the same production management in the same plot, variety, transplanting time, fertilization, planting density, and number of leaves left, and the same growth and appearance of the tobacco plants were used as control tobacco plants. When the central flower of the control tobacco plant is open, the upper inflorescence of the tobacco plant and the upper leaves with a leaf length less than 15 cm are removed, and 18 leaves are retained.

[0042] The experimental tobacco plants and the control tobacco plants were harvested and cured in the local conventional way. The upper leaves of the cured experimental tob...

Embodiment 2

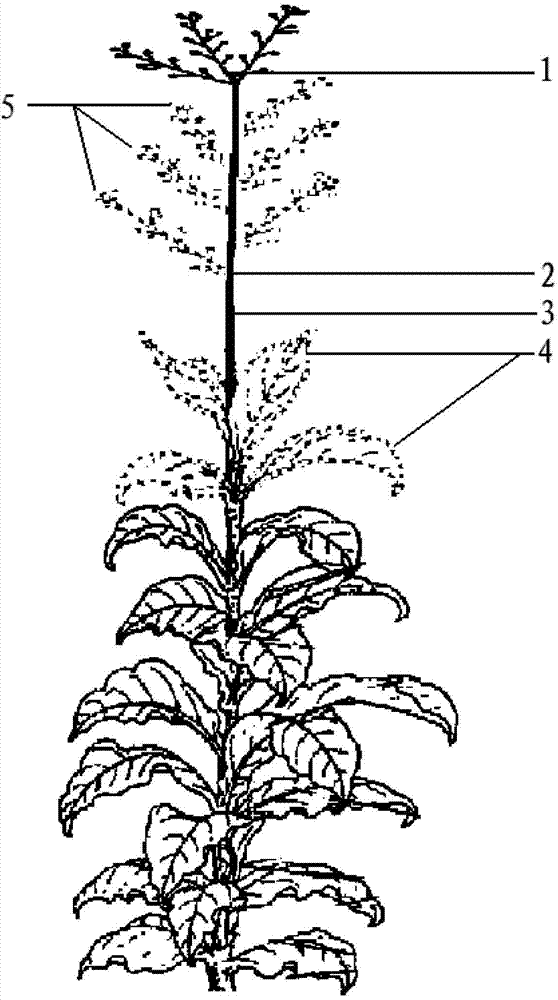

[0043] Embodiment 2 "Beating leaves and leaving flowers" cultivation technique

[0044] The experimental tobacco strains were selected from Guizhou production areas, and the experiment was repeated 3 times in 3 plots, with 20 plants in each plot. 7 days before the central flower opens, the tobacco plant is topped and 2 top flowers and 20 leaves are reserved.

[0045] Another 20 tobacco plants with the same production management in the same plot, variety, transplanting time, fertilization, planting density, and number of leaves left, and the same growth and appearance of the tobacco plants were used as control tobacco plants. The upper inflorescence of the tobacco plant and the upper leaves with a leaf length less than 15 cm were removed 7 days before the central flower of the control tobacco plant opened, and 20 leaves were retained.

[0046] The experimental tobacco plants and the control tobacco plants were harvested and cured in the local conventional way. The upper leave...

Embodiment 3

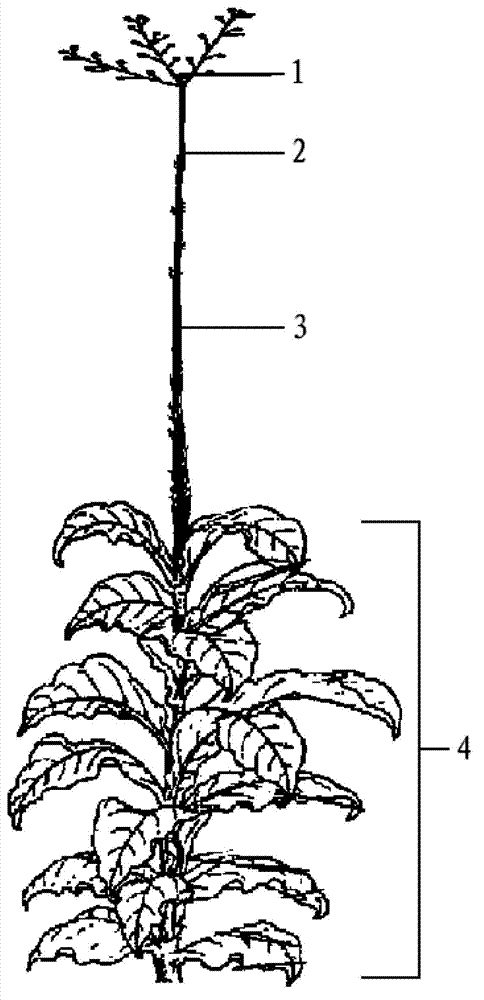

[0047] Embodiment 3 "Beating leaves and leaving flowers" cultivation technique

[0048] The experimental tobacco strains were selected from Guizhou production areas, and the experiment was repeated 3 times in 3 plots, with 20 plants in each plot. 7 days after the central flower bloomed, the tobacco plant was topped and 1 top flower and 22 leaves were reserved.

[0049] Another 20 tobacco plants with the same production management in the same plot, variety, transplanting time, fertilization, planting density, and number of leaves left, and the same growth and appearance of the tobacco plants were used as control tobacco plants. The upper inflorescence of the tobacco plant and the upper leaves with a leaf length less than 15 cm were removed 7 days after the central flower of the control tobacco plant opened, and 22 leaves were retained.

[0050] The experimental tobacco plants and the control tobacco plants were harvested and cured in the local conventional way. The upper leav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com