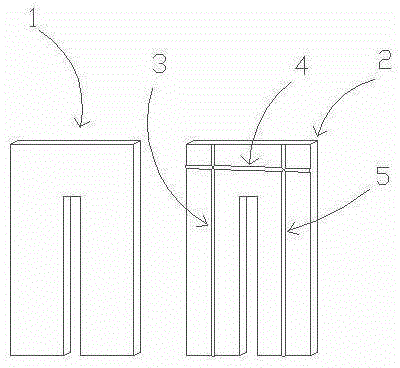

Anti-clogging capillary drip irrigation emitter with flat plate superimposition structure

A drip irrigator and flat plate technology, applied in the field of anti-clogging capillary drip irrigators, can solve problems such as easy clogging, achieve balanced dripping speed, avoid water evaporation and microbial growth, and reduce the average cost of use and repeated construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] best practice

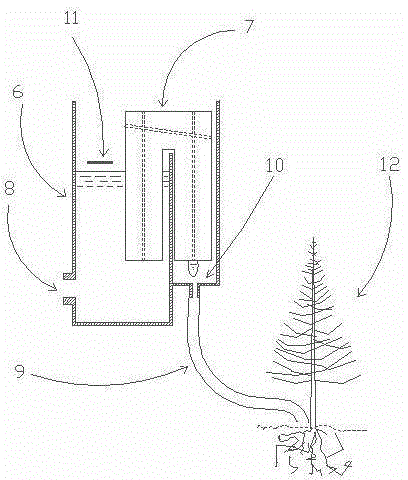

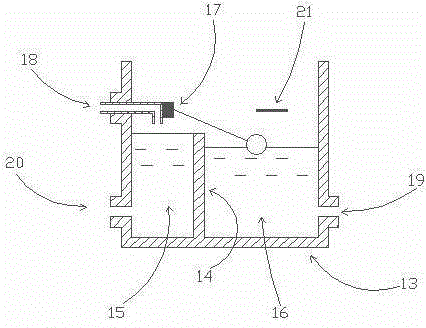

[0046] Select the float flat glass with standard quality and stable chemical properties to make the micro-water delivery device, and control the thickness and number of capillary marks, running marks and gravity marks in the process of making the micro-water delivery device, and control the dripping speed of the micro-water delivery device It is made into 3-4 drops / minute, and the daily water supply of each drip irrigation port is about 1000ml, which is more suitable for the needs of plant growth, and adopts an uninterrupted drip irrigation system without manual intervention, which saves labor input.

[0047] Beneficial effect

[0048] In the capillary drip irrigation device, since the passage of water from the container to the outside of the container is a narrow gap rather than a micropore, the driving force for water movement is the capillary force of the narrow gap on the water rather than the pressure, and the capillary force only acts on the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com