Pigsty with toilets

A technology for pig houses and toilets, applied in the field of pig houses, which can solve the problems of not conforming to the physiological habits of pigs, unfavorable storage of a large amount of feces, and small collection tank space, and achieves the effect of simple structure, convenient operation, and maintenance of air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

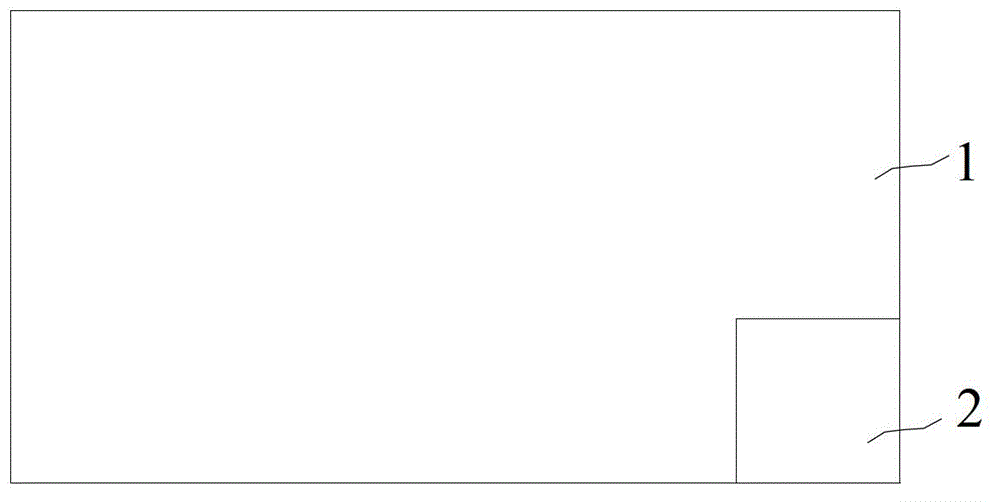

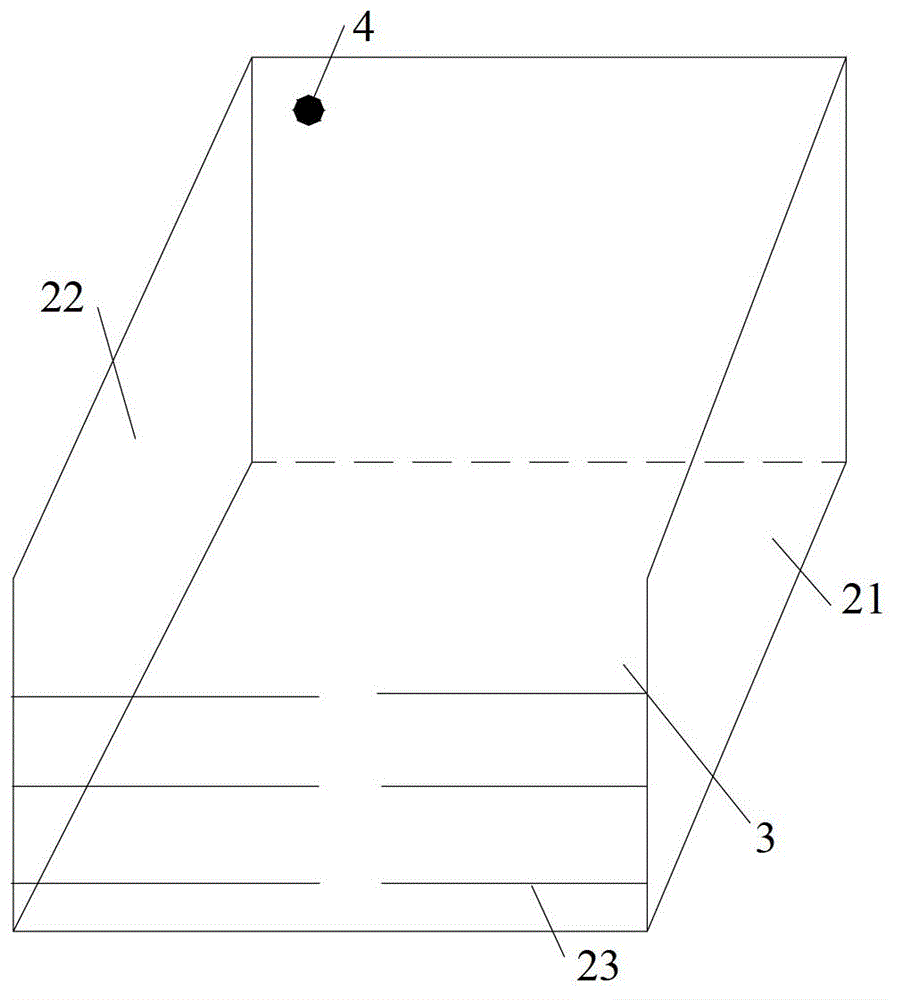

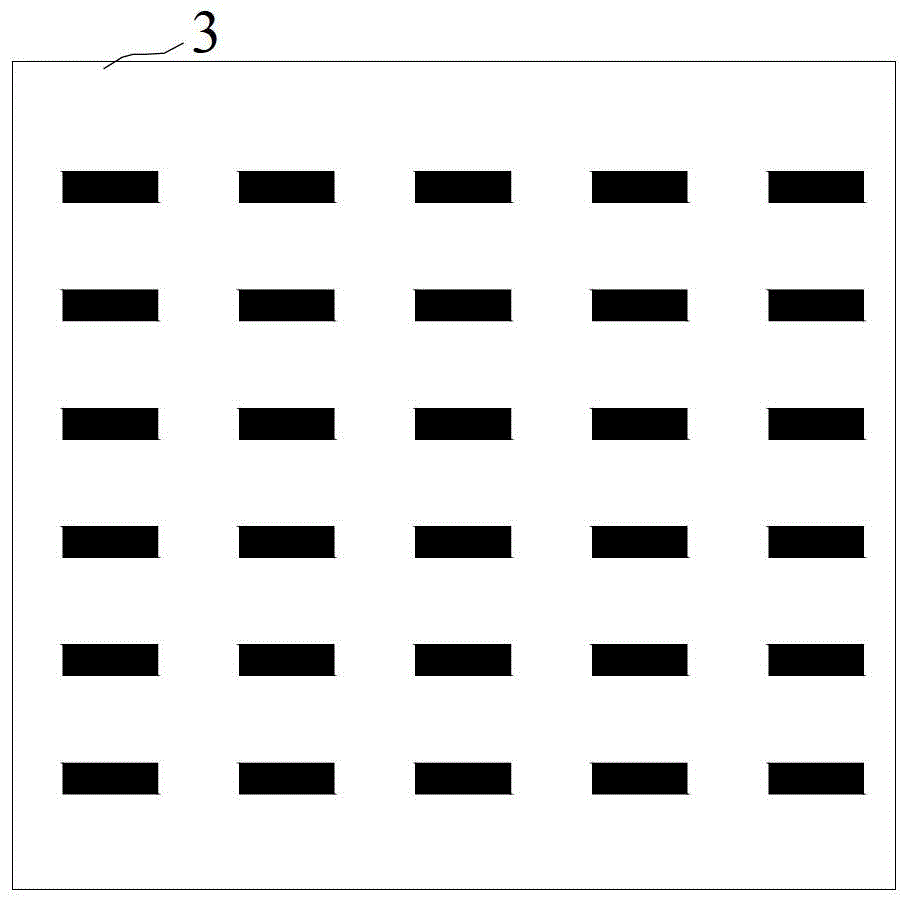

[0031] Such as figure 1 and figure 2 As shown, there is an excretion area 2 in the lower right corner of a column 1 of the piggery in the present embodiment, i.e. a lavatory. The two sides of the opening of the area 2 are hinged with iron rails 23 to realize the sealing of the excretion area 2 .

[0032] In order to detect whether pigs exist in the excretion area 2 at any time, a sensor is installed on the wall opposite to the iron fence 23, such as an infrared sensor 4, and an automatic door lock is installed on the iron fence 23, and the infrared sensor 4 can send control to the automatic door lock. Signal. When a pig enters the excretion area 2, the automatic door lock receives the control signal sent by the infrared sensor 4, so the automatic door lock is locked in one direction in the direction that the iron fence 23 enters the toilet, and other pigs cannot enter the excretion area 2 at the same time. Pigs in the excretion area 2 can easily get out of the toilet. The...

Embodiment 2

[0040] This embodiment discloses another piggery with lavatories, the part on the ground of the excretion area is the same as that of Embodiment 1, the difference is that the structure of the cesspit 5 is different from that of Embodiment 1, and the cesspit 5 of the present embodiment can be Realize solid-liquid separation of feces.

[0041] Such as Figure 5 As shown, the cesspit 5 uses a slope with a slope of 7-10% as the slope 9, which can ensure that most of the pig manure can slide smoothly into the separation chamber 10 outside the pig house that can realize solid-liquid separation.

[0042] In order to realize the solid-liquid separation of feces, the bottom of the separation chamber 10 is a slope 101 with a slope of 1.5%. The slope 101 is connected to the end of the slope 9. The urine will continue to flow downward on the slope 101 and pass through The filtration of the filter screen 102 enters in the defecation pipe 103 . The feces will not continue to slide down on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com