Wide-visual-angle colloid crystal film and preparation method thereof

A technology of colloidal crystals and wide viewing angles, which is applied in the field of colloidal crystal films with wide viewing angles and its preparation, can solve the problems of widened reflection peaks, color brightness, decline, unfavorable applications, etc., to reduce the difference in viewing angles, structural color Brilliant, cheap-to-prepare results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

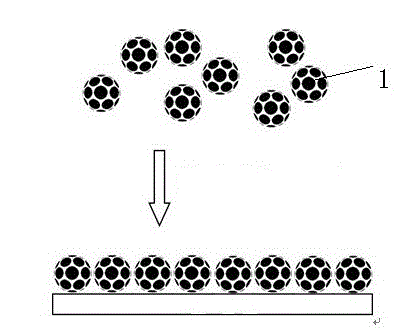

[0036] Example 1 Preparation of colloidal crystal gel film with wide viewing angle of spherical opal structure

[0037] 1. Preparation of colloidal crystal microspheres 1

[0038] The monodispersed 280 nm silica colloidal particles were purified by centrifugation, and the mass percentage of colloidal nanoparticles in the colloidal particle solution was adjusted to 20%. After ultrasonic dispersion, it was used as the water phase in the microfluidics. The external phase is n-hexadecane containing surfactant. The generated droplets were collected, and after being heated and solidified, they were put into a muffle furnace for calcination at 800°C to improve the stability of the microspheres.

[0039] 2. Gel immobilization to prepare colloidal crystal film with wide viewing angle

[0040] After the prepared colloidal crystal microspheres 1 were treated with plasma for hydrophilization for 3 min, they were added to the mixed solution of acrylamide and methylenebisacrylamide (29:1 ...

Embodiment 2

[0042] Example 2 Preparation of Colloidal Crystal Gel Film with Spherical Inverse Opal Structure and Wide Viewing Angle

[0043] 1. Preparation of colloidal crystal microspheres 1

[0044]The monodisperse 200 nm silica colloidal particles were purified by centrifugation, and the mass percentage of colloidal nanoparticles in the colloidal particle solution was adjusted to 35%. After ultrasonic dispersion, it was used as the water phase in the microfluidics. The external phase is silicone oil containing surfactant. The generated droplets were collected, heated and solidified, washed, and then put into a muffle furnace for calcination at 800°C to improve the stability of the microspheres.

[0045] 2. Gel immobilization to prepare colloidal crystal film with wide viewing angle

[0046] After the prepared colloidal crystal microsphere 1 was treated overnight with isoconcentrated sulfuric acid hydrogen peroxide (7:3), 15% polyethylene glycol diacrylate containing photoinitiator HM...

Embodiment 3

[0048] Example 3 Preparation of agarose colloidal crystal gel film with wide viewing angle

[0049] 1. Preparation of colloidal crystal gel microspheres

[0050] The monodisperse 180 nm polystyrene colloidal particles were centrifuged and purified, and the mass percentage of colloidal nanoparticles in the colloidal particle solution was adjusted to 30%, which was used as the aqueous phase after ultrasonic dispersion. Using n-hexadecane containing surfactant as the oil phase, it is emulsified into liquid droplets by direct stirring method, after being heated and solidified and washed, it is put into a muffle furnace for calcination at 800°C to improve the stability of the microspheres.

[0051] 2. Preparation of colloidal crystal film with wide viewing angle by adsorption method

[0052] After the prepared colloidal crystal microspheres 1 were treated with plasma hydrophilicity for 4 min, they were soaked in a certain concentration of agarose gel solution and kept in a water b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com