Structural color sunglass lens and forming process thereof

A molding process and structural color technology, applied in glasses/goggles, metal material coating process, and other household appliances, etc., can solve the problems of uncontrollable preparation process, incapable of large-scale manufacturing, and limited structural color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

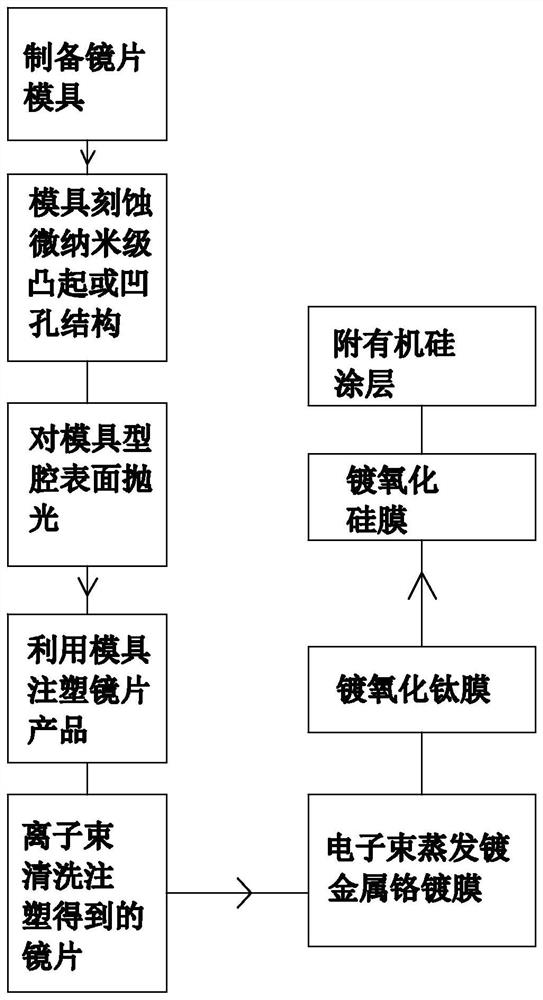

[0031] like figure 1 As shown in the figure, a molding process of a structural color sunglass lens includes the following steps: S1, an injection mold of the lens is prepared by electroforming;

[0032] S2, typesetting the structural color pattern to be attached to the lens, and then etching the pattern in the cavity of the injection mold by ion beam etching to form an array of micro-nano-scale convex structures or concave hole structures. The thickness or depth of the nano-scale convex structure or concave structure is 100-200 nanometers;

[0033] S3, polishing the cavity surface with ion beam etching;

[0034] S4, the injection mold obtained in step S1 is installed on the injection molding machine for injection molding, the injection molding raw material is dried by a dehumidifier for 6 hours, the drying temperature is 80 °C, the mold is preheated to 35 °C, and the injection molding adopts five-stage segment injection. , in which the injection pressure of the first stage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com