Fluidic generator

A technology of jet flow generator and high-voltage AC, which is applied in the direction of spraying electric energy devices, chemical instruments and methods, and cleaning methods using gas flow, etc., can solve the problems of non-concentrated air flow energy, secondary pollution of components, and inability to be cleaned. Achieve the effect of concentrated jet energy, small divergence, and simple composition and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

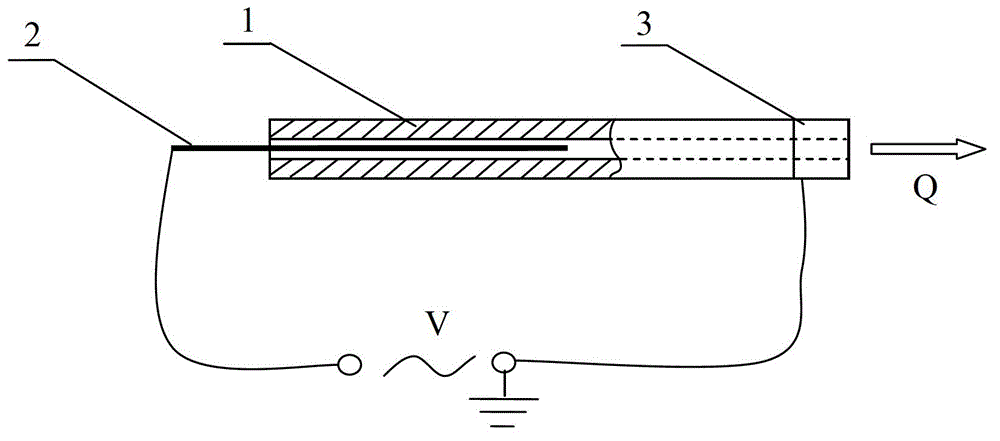

[0021] see figure 1 , The present invention is equipped with a round tube 1 (insulating dielectric tube), a needle electrode 2, a ring electrode 3 (a strip-shaped copper foil ring electrode) and a high-voltage AC power supply. The material of the circular tube 1 is quartz glass. The circular tube 1 has an inner diameter of 1 mm, a tube wall thickness of 1 mm, and a length of 30 mm. The needle electrode 2 is inserted from the rear end of one end 1 of the round tube, and the ring electrode 3 is wound on the outer wall of the front end of the round tube 1 . The needle electrode 2 is a copper wire needle electrode made of copper wire with a diameter of 0.3 mm. The ring electrode 3 is a strip-shaped copper foil ring electrode made of copper foil with a thickness of 0.02 mm and a width of 5 mm. The axial distance between the needle electrode 2 and the ring electrode 3 is 10mm, and the needle electrode 2 and the ring electrode 3 are respectively electrically connected to two outpu...

Embodiment 2

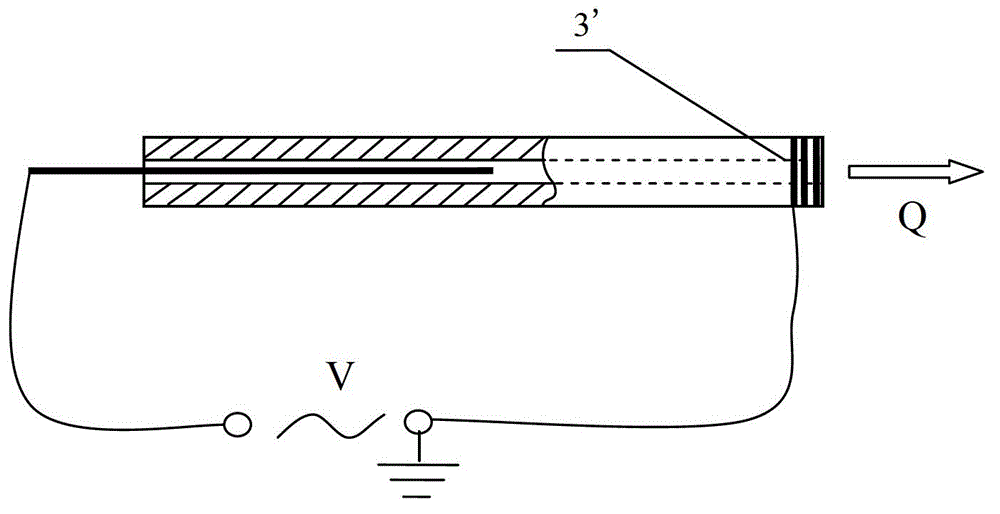

[0026] see figure 2 , similar to Embodiment 1, the only difference is that the ring electrode 3' is made of 3 turns of copper wire with a diameter of 0.3 mm to bind the ring electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com