Viscosity modifier for high or ultrahigh-strength concrete

A technology of ultra-high-strength concrete and viscosity modifier, which is used in the field of high-strength or ultra-high-strength concrete viscosity modifier, can solve the problems of high-strength or ultra-high-strength concrete viscosity, reduce concrete viscosity, low cost, etc. The effect of reducing viscosity and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

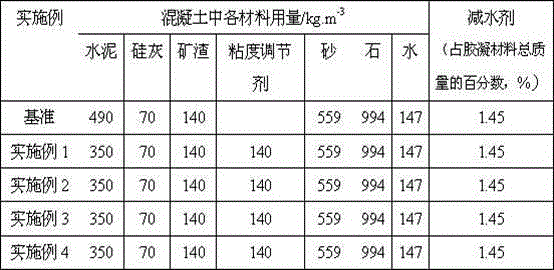

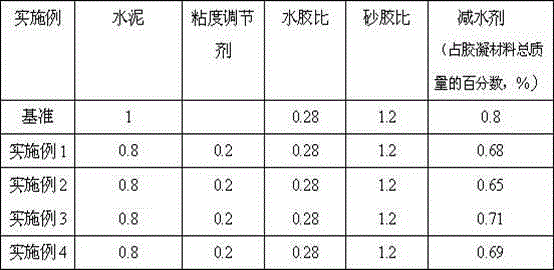

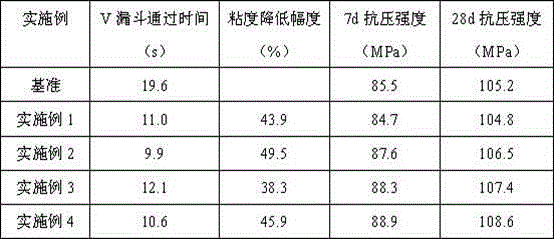

Examples

Embodiment 1

[0031] A high-strength or ultra-high-strength concrete viscosity modifier, which is made by mixing the following substances according to mass percentage:

[0032] Silica fume 3%

[0033] Fly Ash 15%

[0035] Limestone powder 80%;

[0036] Among them, the average particle diameter of the limestone powder is 3.6 μm.

Embodiment 2

[0038] A high-strength or ultra-high-strength concrete viscosity modifier, which is made by mixing the following substances according to mass percentage:

[0039] Silica fume 10%

[0040] Fly Ash 20%

[0042] Quartz powder 68%;

[0043] Among them, the average particle size of the quartz powder is 2.4 μm.

Embodiment 3

[0045] A high-strength or ultra-high-strength concrete viscosity modifier, which is made by mixing the following substances according to mass percentage:

[0046] Silica fume 2%

[0047] Fly Ash 15%

[0049] Ultrafine Mineral Powder 25%

[0050] Limestone powder 55%;

[0051] Among them, the average particle size of ultrafine mineral powder is 6.9 μm, and the average particle size of limestone powder is 5.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com