Crumb rubber powder composited regenerated all-weather road cold-patch material and production method thereof

A composite regeneration and cold-patch material technology, which is applied in the field of cold-patch materials for the recycling of waste rubber powder and asphalt road milling waste, can solve the problem of the reduction of the cohesive performance and water resistance of recycled road cold-patch materials, and the failure of waste rubber powder. Composite recycling, low temperature operation and easy performance reduction, etc., to achieve the effect of resource saving, environmental friendliness, full use of energy, and improvement of anti-rutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

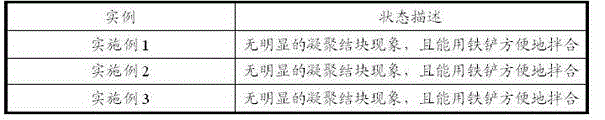

Embodiment 1

[0037] 1. Material preparation:

[0038] Diesel: use ordinary 0 # diesel fuel.

[0039] Base asphalt: Grade A 70# road petroleum asphalt is used, and the asphalt produced by CNOOC Taizhou Plant is used in this example.

[0040] Waste rubber powder: waste truck tires with high natural rubber content were used and obtained by shearing and crushing. The particle size of the waste rubber powder used in this example was 40 mesh.

[0041] Asphalt road milling waste: Beijing-Shanghai high-speed surface layer milling waste is used. Before use, the milling material needs to be sieved to remove larger agglomerated milling materials. The particle size of the milling material after sieving is: 3-16mm.

[0042] Mineral powder: Mineral powder processed from limestone is required. The particle size requirement is that the pass rate of 0.6mm sieve hole is 100%, the pass rate of 0.15mm sieve hole is greater than 90%, and the pass rate of 0.075mm sieve hole is greater than 75%.

[0043] The...

Embodiment 2

[0058] 1. Material preparation:

[0059] Diesel: use ordinary -10 # diesel fuel.

[0060] Base asphalt: Grade A 90# road petroleum asphalt is used, and the asphalt produced by CNOOC Taizhou Plant is used in this example.

[0061] Waste rubber powder: waste truck tires with high natural rubber content are used and obtained by crushing. The particle size of the waste rubber powder used in this embodiment is 50 mesh.

[0062]Asphalt road milling waste: Beijing-Shanghai high-speed surface layer milling waste is used. Before use, the milling material needs to be sieved to remove larger agglomerated milling materials. The particle size of the milling material after sieving is: 3-16mm.

[0063] Mineral powder: Mineral powder processed from limestone is required. The particle size requirement is that the pass rate of 0.6mm sieve hole is 100%, the pass rate of 0.15mm sieve hole is greater than 90%, and the pass rate of 0.075mm sieve hole is greater than 75%.

[0064] New aggregate:...

Embodiment 3

[0076] 1. Material preparation:

[0077] Diesel, using ordinary 0 # diesel fuel.

[0078] Base asphalt: 70# road petroleum asphalt is used, and the asphalt produced by CNOOC Taizhou Plant is used in this example.

[0079] Waste rubber powder: waste truck tires with high natural rubber content are used and obtained by crushing. The particle size of the waste rubber powder used in this embodiment is 80 mesh.

[0080] Asphalt road milling waste: Beijing-Shanghai high-speed surface layer milling waste is used, and the milling material needs to be screened before use to remove larger agglomerated milling materials. The particle size of the milling material after sieving is 3-20mm.

[0081] Mineral powder: Mineral powder processed from limestone is required. The particle size requirement is that the pass rate of 0.6mm sieve hole is 100%, the pass rate of 0.15mm sieve hole is greater than 90%, and the pass rate of 0.075mm sieve hole is greater than 75%.

[0082] New aggregate: Zh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com