Glazed ceramic plated with metal patterns and its mold and manufacturing technology

A technology of ceramic products and metal plating, applied in the field of ceramic products, can solve the problems of no market development space, difficulty in large-scale promotion and application, unfavorable energy saving and environmental protection, etc., and achieves the advantages of large-scale promotion and application, elegant, luxurious, economical, practical, and convenient The effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

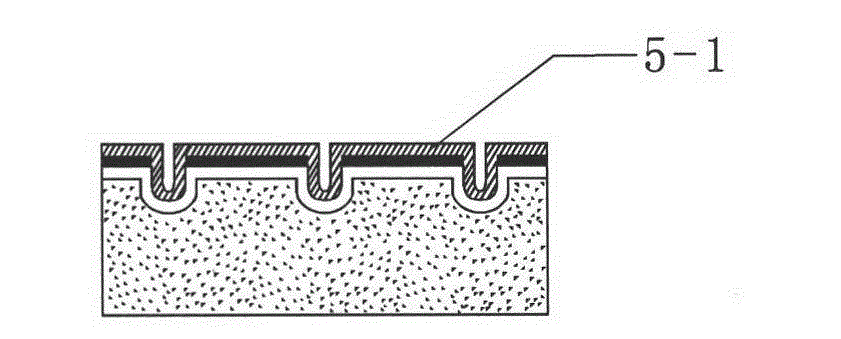

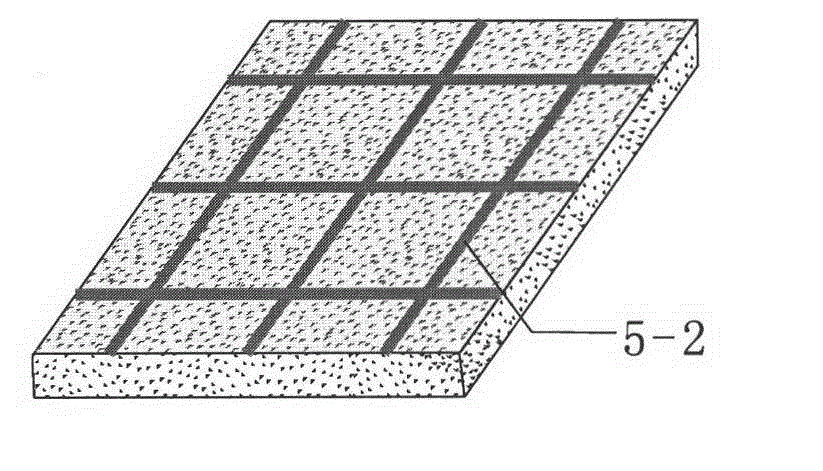

[0035] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing, as Figure 6A , Figure 6B Shown: a glazed ceramic product with a metal-plated pattern, including a ceramic product body 2-1, a glaze layer 3-1, and a metal-plated pattern 5-2, characterized in that the upper surface of the ceramic product body It has a green body concave pattern 2-2 formed by extrusion using a relief pattern mold press, and a glazed layer 3-1 with rich colors formed on the upper surface after color printing and secondary sintering. The glazed layer The glazed concave grooves 3-2 are formed along with the body concave grooves, and a metal plating layer is attached to the glazed concave grooves 3-2, that is, the metal-plated pattern 5-2.

[0036] The metal coating 5-1 is titanium gold, titanium silver or zirconium silver.

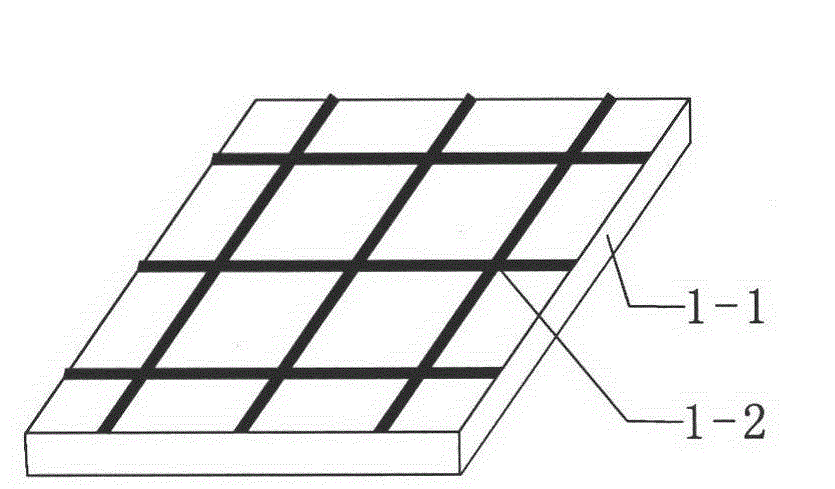

[0037] Such as Figure 1A , Figure 1B Shown: a relief pattern mold for the production of glazed ceramic products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com