Composite vibration insulator for electrostatic deduster and preparation method thereof

An electrostatic precipitator and insulator technology, which is applied in the field of environmental protection and dust removal, can solve the problems of expensive later maintenance, not conducive to energy saving and consumption reduction, and easy to condense water on the surface, so as to achieve not easy to flashover or breakdown, light weight and short production cycle long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

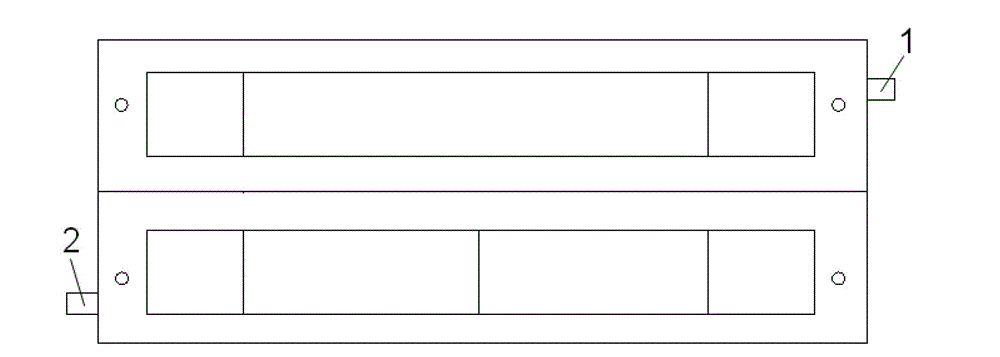

[0024] see figure 1 , composite rapping insulators for electrostatic precipitators, according to weight percentage, including 75%-80% chopped fiber, 10%-8% high-temperature resistant epoxy resin, 10%-8% high-temperature resistant curing agent, 1 %-2% accelerator, 1%-5% nano-scale quartz powder and 0.5%-1% nano-flame retardant.

[0025] The technical scheme for realizing the invention is:

[0026] 1Materials used for polymer composite rapping insulators (shafts).

[0027] Including 1) chopped fiber, 2) high temperature resistant epoxy resin, 3) high temperature resistant curing agent, 4) accelerator, 5) nano-scale quartz powder, 6) nano flame retardant and other auxiliary materials.

[0028] 2 The proportion of materials used is: according to the weight percentage, the polymer composite rapping insulator (shaft) composition contains 75%-80% of chopped fiber. 10%-8% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com