Special water-based ink for printing tipping paper for cigarette and preparation method thereof

A technology of tipping paper and water-based ink for cigarettes, applied in the direction of ink, application, household appliances, etc., can solve the problems of thinning, slow drying, increase printing cost, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

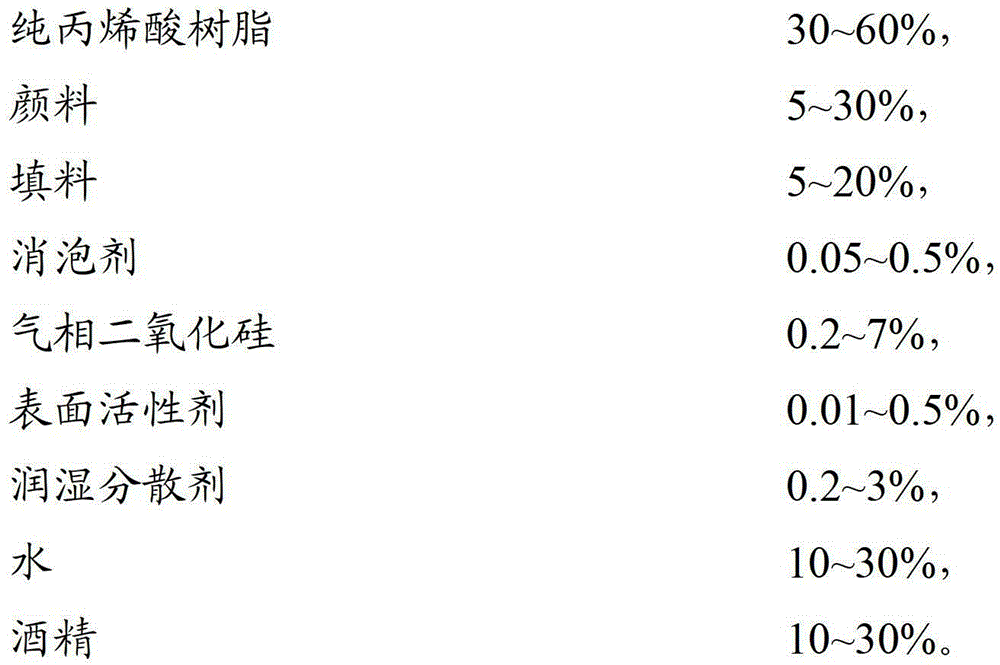

[0049] Water-based inks are made from the following ingredients:

[0050]

[0051] (1) Material preparation and weighing: Weigh the pure acrylic resin, pigment, filler, defoamer, fumed silica, surfactant, wetting and dispersing agent, water, and alcohol one by one in proportion for later use;

[0052] (2) Mixing and stirring: Mix the pure acrylic resin, pigment, filler, defoamer, wetting and dispersing agent, and alcohol prepared in step (1) in order, and add 2 / 3 of the total water first. , at a low speed of 200-400 r / min, feed in turn under stirring, and stir for 10-15 minutes;

[0053] (3) Sand mill dispersion: transfer the uniformly stirred mixture in step (2) into a sand mill for sand mill dispersion, wash the mixing container with 1 / 3 of the total water consumption, add water to the sand mill, and Grind in the mill for 3 to 4 times. When the particle size of the mixture is 150-260nm, the grinding and dispersion are completed;

[0054] (4) Subsequent treatment: Stir the...

Embodiment 2

[0102] Make water-based ink with the following ingredients

[0103]

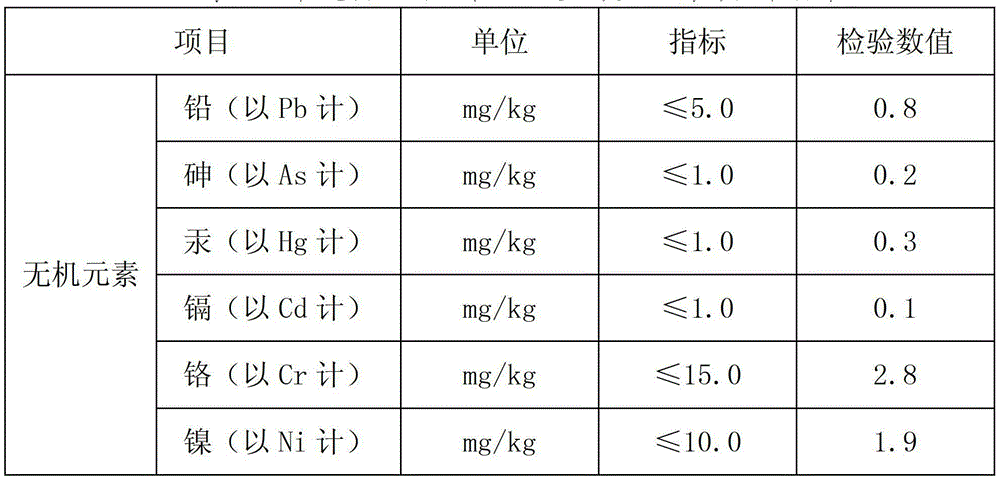

[0104] The preparation method and inspection method are the same as in Example 1, and the product inspection results are shown in Table 5 and Table 6.

Embodiment 3

[0106] Make water-based ink with the following ingredients

[0107]

[0108] The preparation method and inspection method are the same as in Example 1, and the product inspection results are shown in Table 5 and Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com