Preparation method for ardealite-based gelled slurry used for well cementation in oil and gas reservoir

A technology for phosphogypsum and oil and gas reservoirs, which is applied to chemical instruments and methods, drilling compositions, etc., can solve the problems of low utilization rate, secondary pollution, waste of other resources, etc., and achieves low production cost, good repeatability, The effect of suitable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

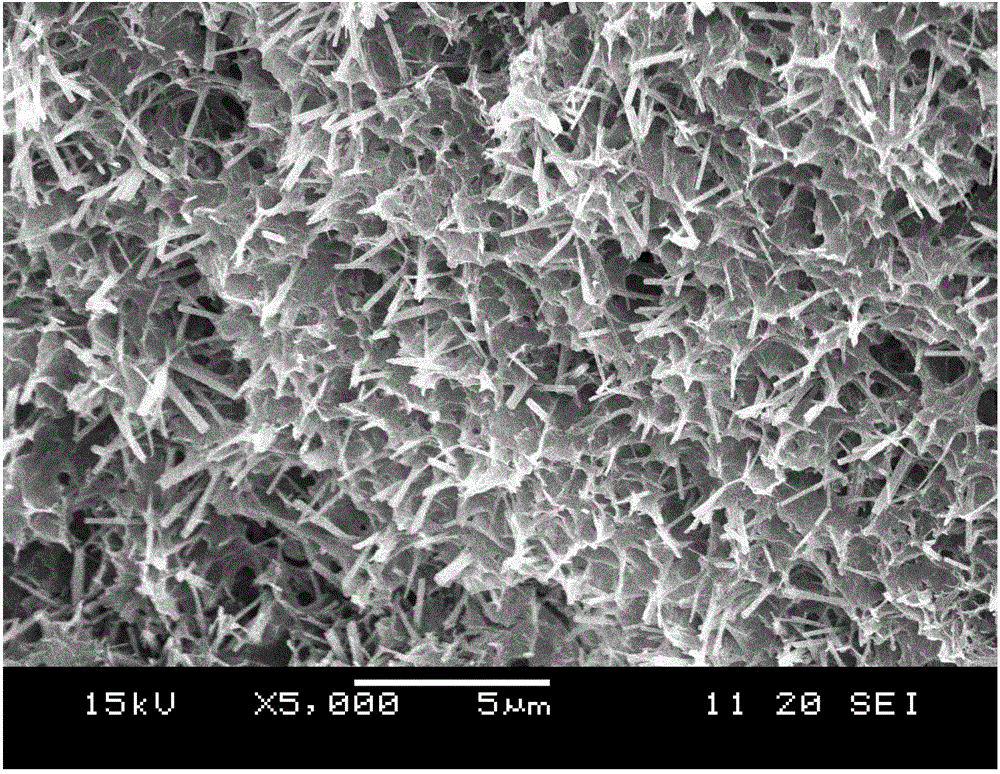

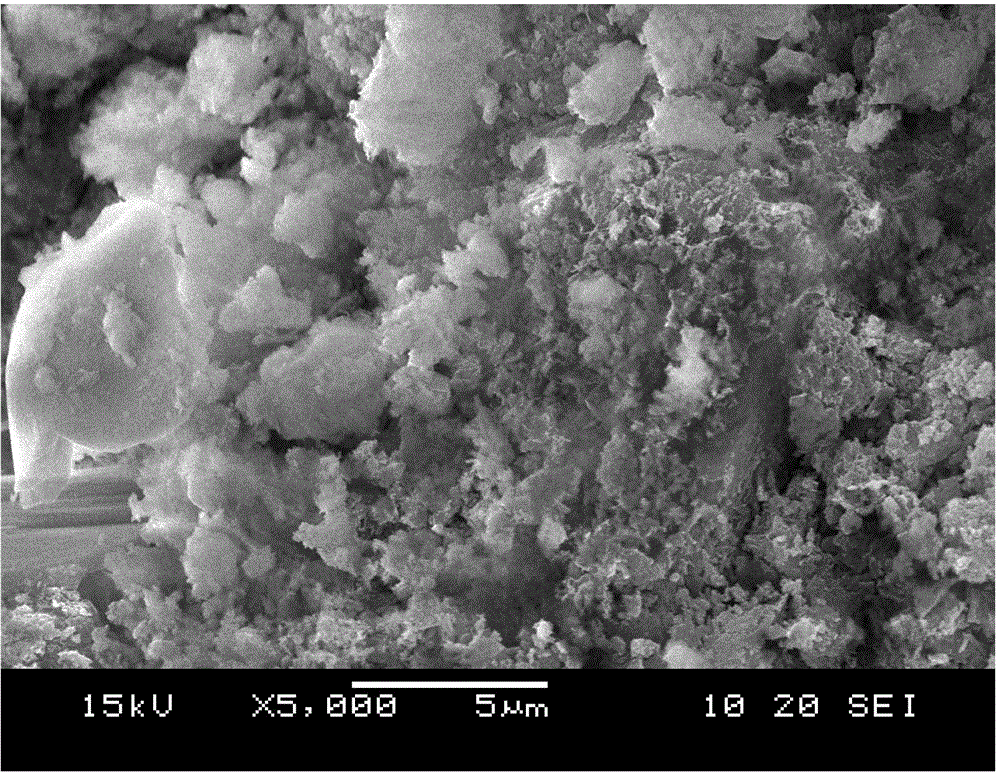

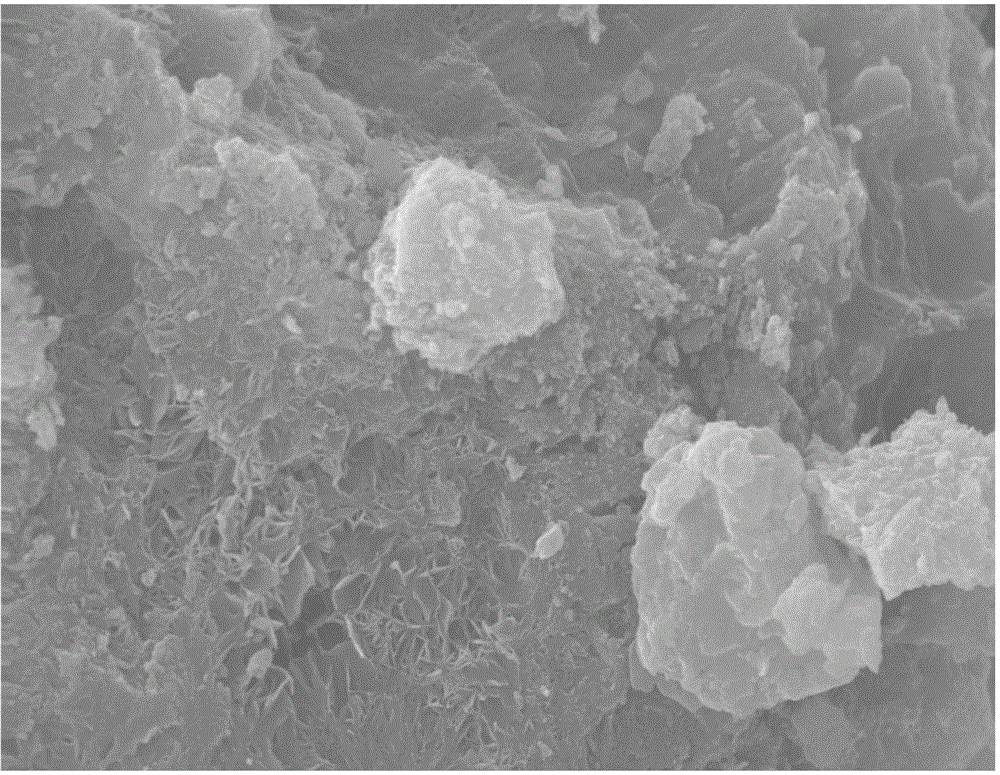

Image

Examples

Embodiment 1

[0026] The preparation method of phosphogypsum-based cementitious slurry for well cementing of oil and gas reservoirs in this embodiment comprises the following steps:

[0027] The first step is to take phosphogypsum, after drying (drying temperature is 45°C±3°C), grinding, and sieving, take phosphogypsum powder with a particle size of 0-0.1mm;

[0028] The second step is to mix phosphogypsum powder with composite reinforcing material and cement at a weight ratio of 5:3:2 to obtain a premix; the composite reinforcing material is composed of the following components in weight ratio:

[0029] CaO

SiO 2

al 2 o 3

P 2 o 5

R 2 o

TiO 2

MgO

26.67%

39.95%

16.85%

0.03%

8.38%

0.94%

7.18%

[0030] Wherein, R is an alkali metal (preferably lithium, sodium, or potassium).

[0031] Step 3: Add water, drag reducer (preferably USZ) and fluid loss control agent (preferably BXF-200L) to the premix. The weight r...

Embodiment 2

[0045] The basic steps of the preparation method of the phosphogypsum-based cementitious slurry for well cementing in oil and gas reservoirs in this example are the same as those in Example 1, except that:

[0046] (1) In the second step, the composite reinforcement is composed of the following components by weight ratio:

[0047] CaO

SiO 2

al 2 o 3

P 2 o 5

R 2 o

TiO 2

MgO

25.57%

45.50%

14.60%

0.06%

7%

0.93%

6.34%

[0048] Wherein, R is an alkali metal (preferably lithium, sodium, potassium).

[0049] (2) In the third step, the weight ratio of premix, water, drag reducer and fluid loss reducer is 1:0.44:0.004:0.01.

[0050] The performances of the gelled slurry made by the present embodiment are shown in the following tables:

[0051] (1) Basic performance:

[0052]

[0053] (2) Thickening performance

[0054]

[0055] In this embodiment, the gelled slurry has zero water separation, ...

Embodiment 3

[0063] The basic steps of the preparation method of the phosphogypsum-based cementitious slurry for well cementing in oil and gas reservoirs in this example are the same as those in Example 1, except that:

[0064] (1) In the second step, the composite reinforcement is composed of the following components by weight ratio:

[0065] CaO

SiO 2

Al 2 o 3

P 2 o 5

R 2 o

TiO 2

MgO

20.55%

51.40%

13.37%

0.08%

8.35%

0.72%

5.53%

[0066] Wherein, R is an alkali metal (preferably lithium, sodium, potassium).

[0067] (2) In the third step, the weight ratio of premix, water, drag reducer and fluid loss reducer is 1:0.44:0.006:0.01.

[0068] The performances of the gelled slurry made by the present embodiment are shown in the following tables:

[0069] (1) Basic performance:

[0070]

[0071] (2) Thickening performance

[0072]

[0073] In this embodiment, the gelled slurry has zero water separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com