Method for preparing epigallocatechin-3-gallate and epigallocatechin gallate by liquid-submerged fermentation

A technology of epicatechin gallate and epigallocatechin, which is applied in the field of biotechnology or bioengineering, and can solve problems such as uneconomical, cumbersome purification process of the mixture, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

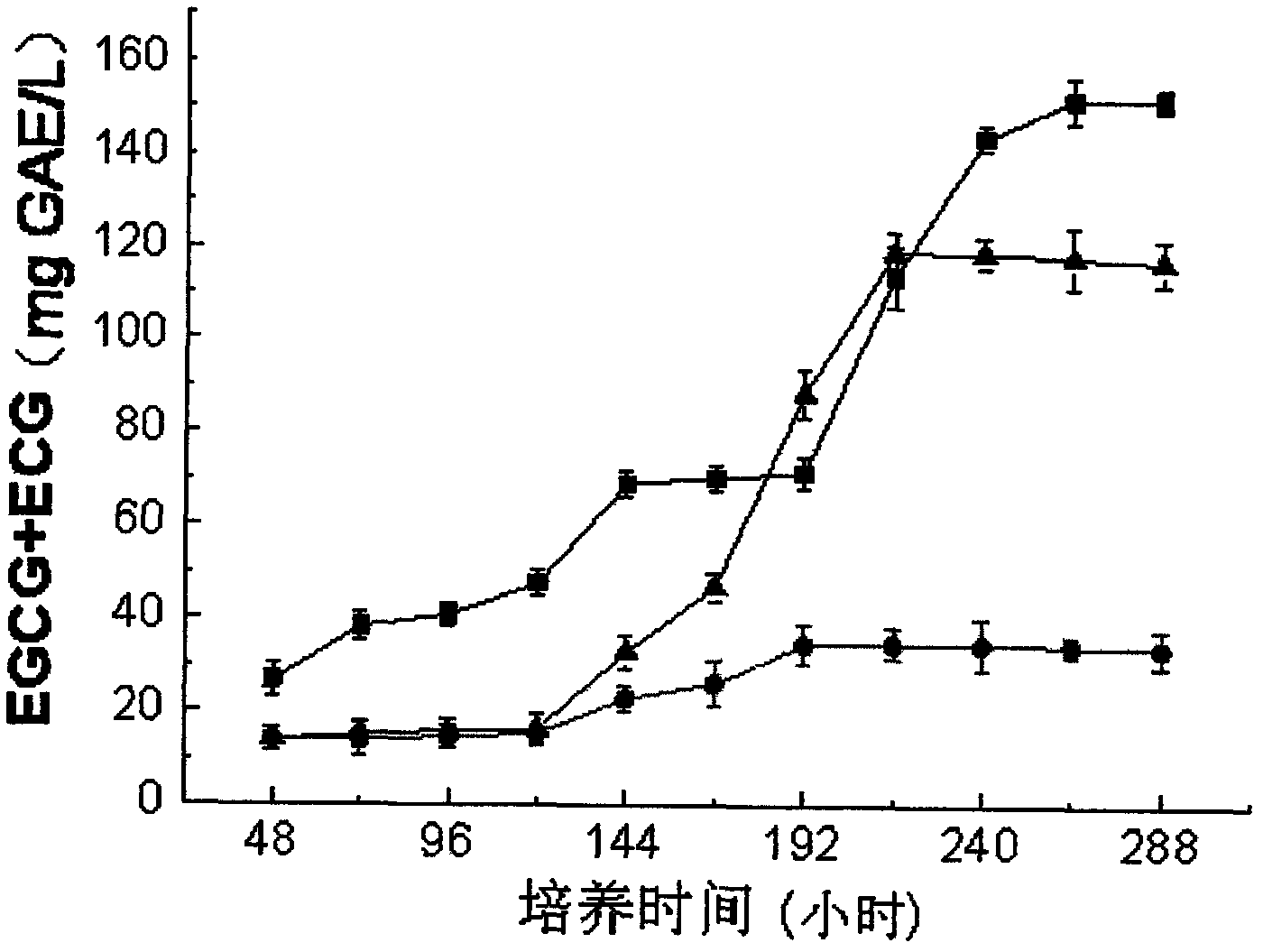

Image

Examples

Embodiment 1

[0021] The mycelia of Inonotus obliquus from the Dutch CBS strain collection were inoculated in the slant medium. The culture temperature was 28° C., and cultured for 240 hours. The fresh slant strains were inserted into a 500mL shake flask filled with 200mL liquid seed medium, cultured at 28°C for 96 hours, and the shaker rotated at 150 rpm. The cultured liquid seeds are inserted into a fermenter equipped with a rice straw fermentation medium according to 10% (v / v). Incubate at 28°C for about 288 hours. The air flow rate is 1.0vvm, the internal pressure is 0.2 kg / cubic centimeter, and the stirring speed is 140 rpm.

[0022] In Example 1, the slant strains were cultured, and the composition of the culture medium was (g / 100mL): 25 malt extracts, 4 peptones, 15 agar, and the pH value was 5.4-5.6.

[0023] Shake flask seed culture in this example 1, medium composition (g / 100mL): glucose 3, peptone 0.4, yeast extract 0.1, KH2PO4 0.1, MgSO4 0.15, CaCl2 0.01.

[0024] Submerged ...

Embodiment 2

[0029] The mycelia of Inonotus obliquus from the Dutch CBS strain collection were inoculated in the slant medium. The culture temperature was 28° C., and cultured for 240 hours. The fresh slant strains were inserted into a 500mL shake flask containing 200mL liquid seed medium, and cultured at 28°C for 96 hours with a shaker speed of 140 rpm. The cultivated liquid seeds are inserted into the fermenter equipped with the sawdust fermentation medium according to 10% (v / v). Incubate at 28°C for about 302 hours. The air flow rate is 0.5vvm, the internal pressure is 0.1 kg / cubic centimeter, and the stirring speed is 140 rpm.

[0030] In Example 2, the slant strains were cultured, and the composition of the culture medium was (g / 100mL): 25 malt extracts, 4 peptones, 15 agar, and the pH value was 5.4-5.6.

[0031] Shake flask seed culture in Example 2, medium composition (g / 100mL): glucose 3, peptone 0.4, yeast extract 0.1, KH2PO4 0.1, MgSO4 0.15, CaCl2 0.01. The shaker rotates at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com