Dual-channel gas state mercury exhaust gas sampling system

A sampling system, gaseous mercury technology, applied in the direction of sampling devices, etc., can solve the problems of large outdoor temperature interference of conduction temperature difference, corrosion damage of sampling equipment, instrument damage, etc., to improve the measurement accuracy of the front temperature of the meter, avoid corrosion, and avoid breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

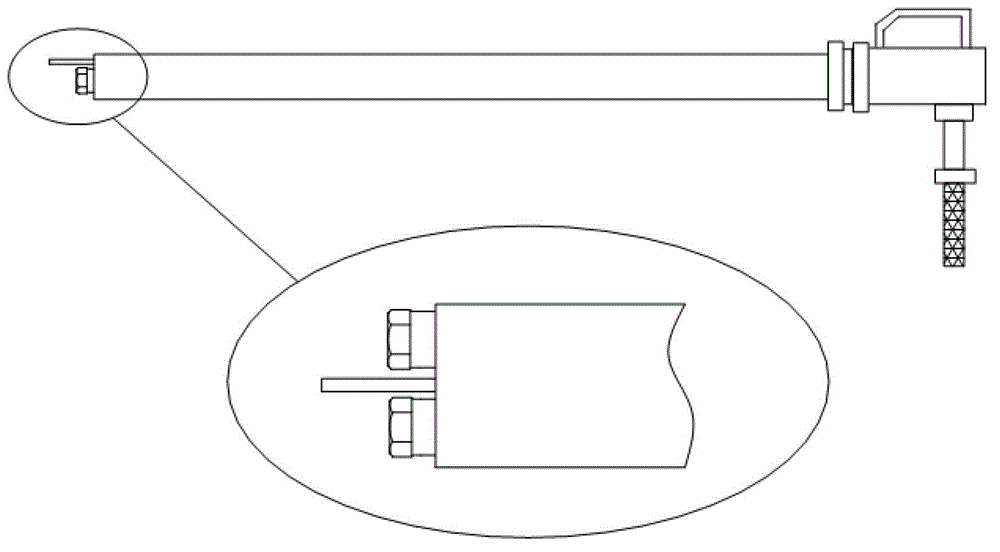

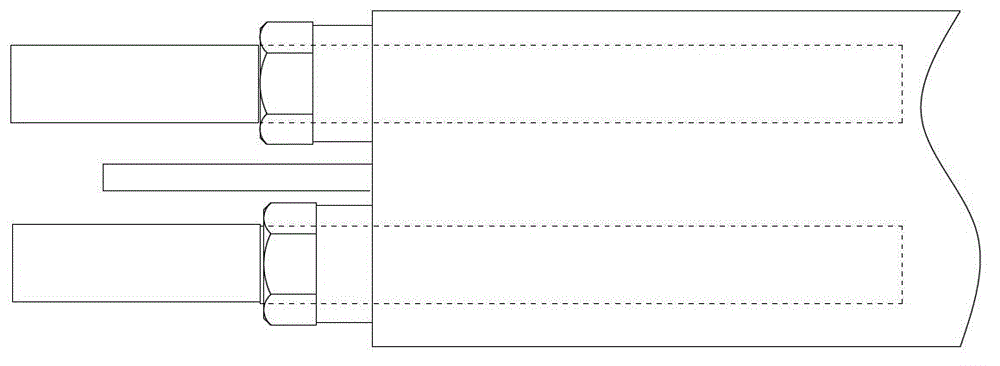

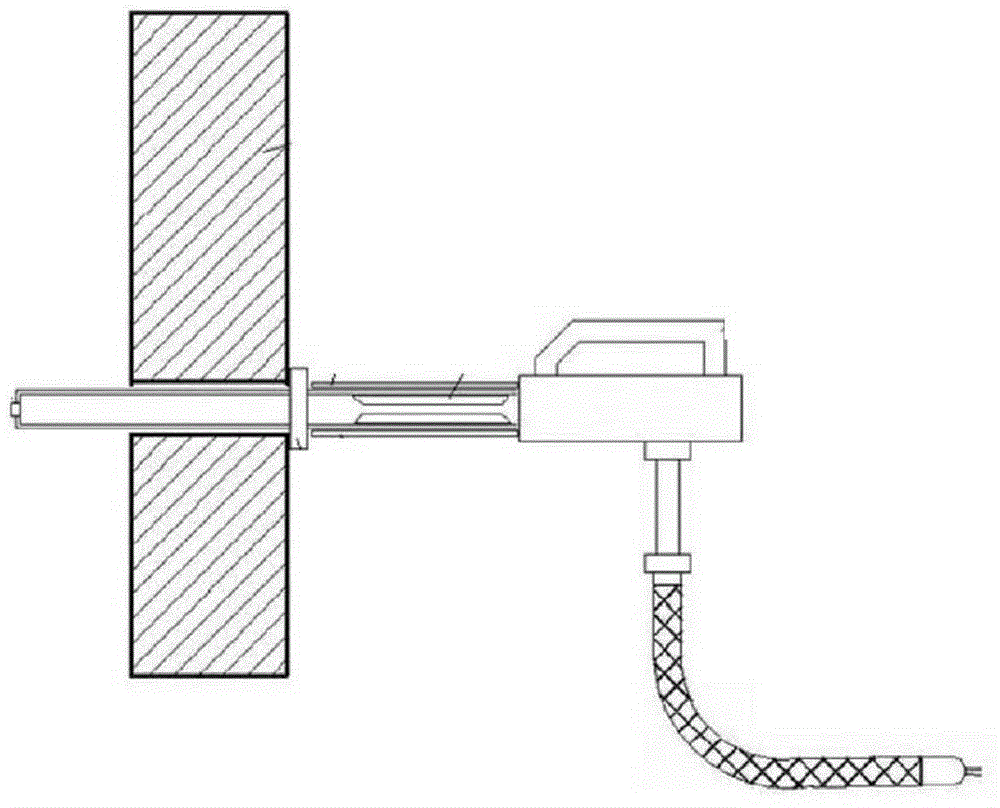

[0027] Figure 4 It is a structural schematic diagram of the sampling system of the present invention. The sampling gun 4 is fixed on the flue wall 2, and the detailed enlarged view of the front end is shown as Figure 5 shown. In the present invention, the installation position of the adsorption tube 3 is designed at the front of the sampling gun 4, which can directly contact the flue gas to be collected, avoiding the absorption and sampling after a section of pipeline, and reducing the influence of the pipeline on the adsorption of mercury. In order to reduce the damage of the absorption tube and the entry of particulate mercury into the sampling tube, the present invention designs a protective cover 1 at the front of the sampling gun, which is composed of a Φ22mm×70mm stainless steel tube 16 and an M10 nut 17, and the stainless steel tube 16 and the nut 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com