Method for preparing non-polar GaN film on r-face sapphire substrate

A sapphire substrate, non-polar technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor quality of non-polar GaN crystals, improve international competitiveness, reduce production costs, and solve The effects of the energy crisis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

[0026] This embodiment is a method for preparing a non-polar GaN film grown on an r-plane sapphire substrate, including the following steps:

[0027] (1) Select the substrate: use the r-plane sapphire substrate, and the orientation of the substrate is 45° off the a-axis

[0028] (2) Using metal-organic chemical vapor deposition (MOCVD) technology, epitaxial non-polar GaN film buffer layer in D125 equipment, the process conditions are: firstly, the substrate is cleaned at high temperature: the substrate is baked at 1100 °C After about 4 hours, reduce the temperature of the reaction chamber, the substrate temperature is 525°C, the reaction chamber pressure is 500torr, V / III is 1700, the thickness of the buffer layer is 25nm, and the carrier gas is hydrogen.

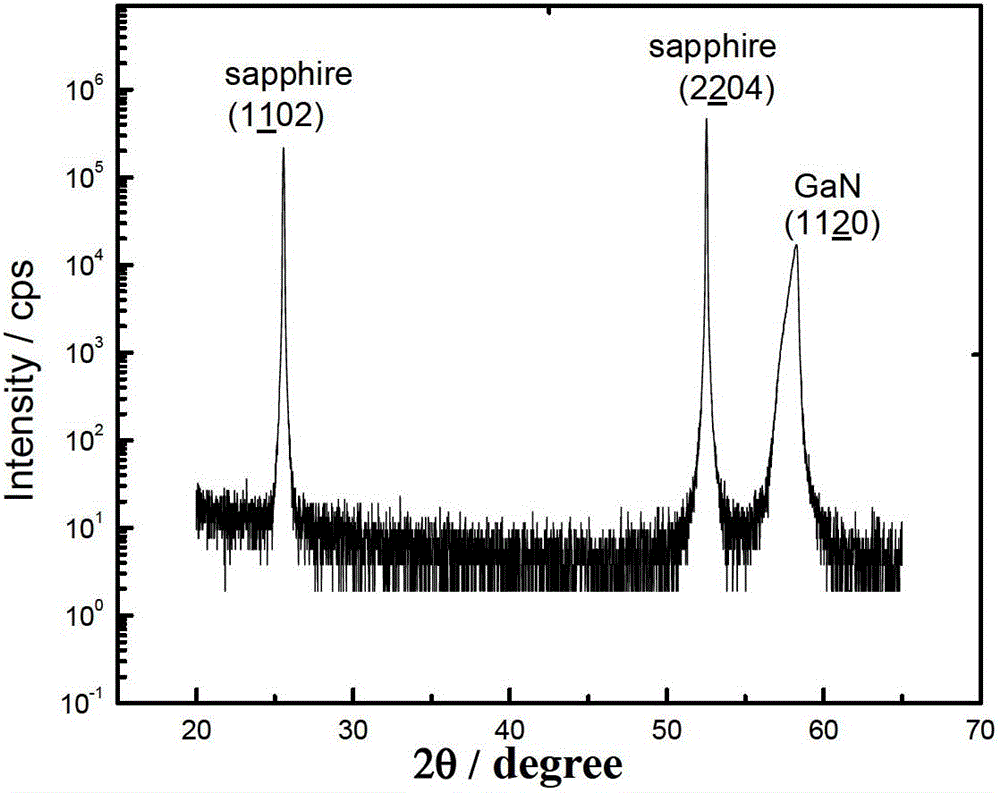

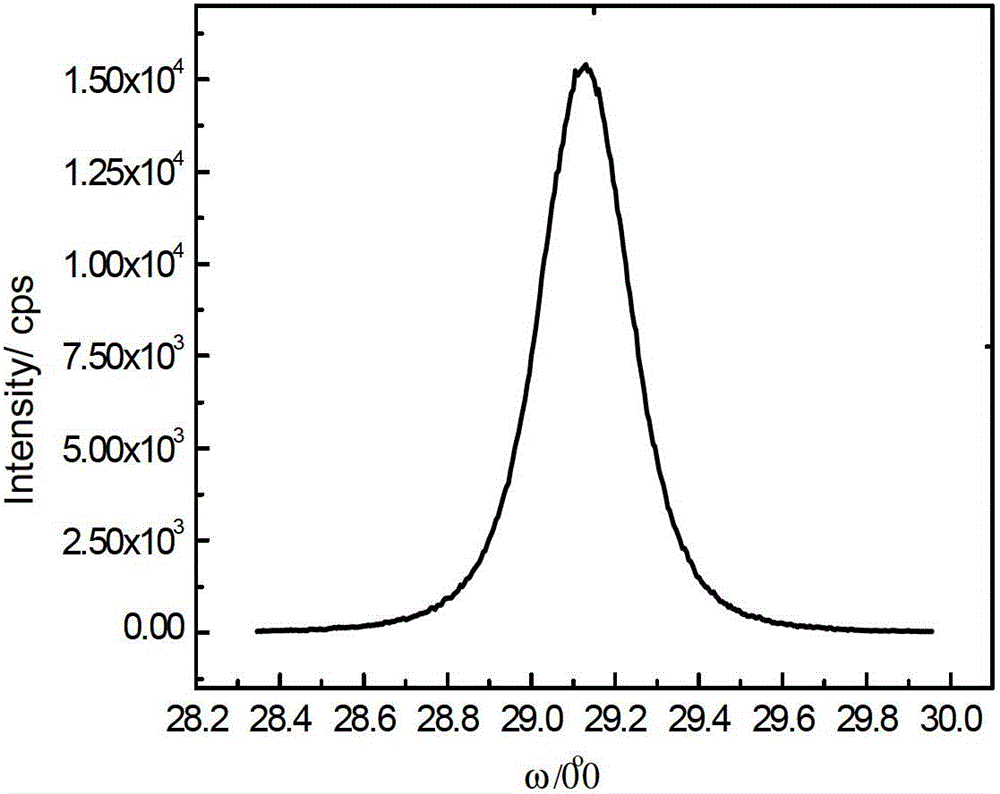

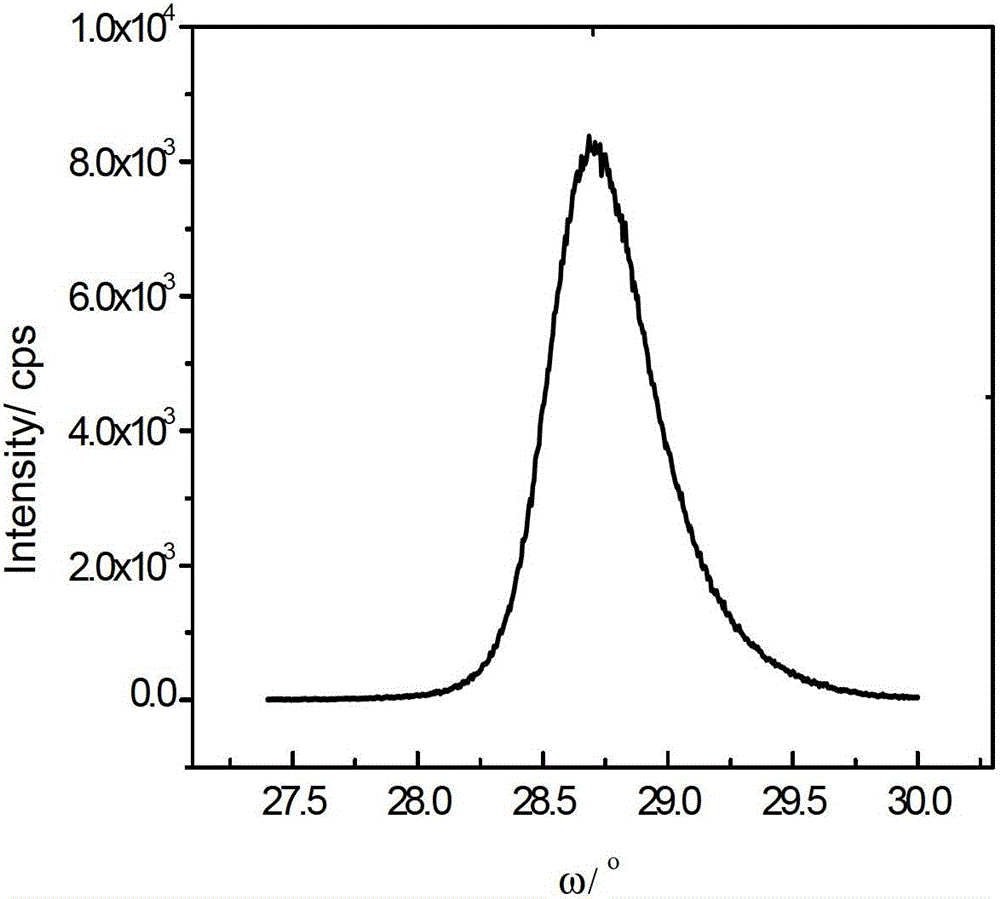

[0029] (3) High-temperature growth a-plane (11-20) GaN process conditions: increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com