Lithium sulphur battery

A lithium-sulfur battery and electrolyte technology, which is applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of reduced electric charge density, active material mass loss, electric capacity decrease, etc., to improve cycle life and power density, Improved ionic conductivity and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

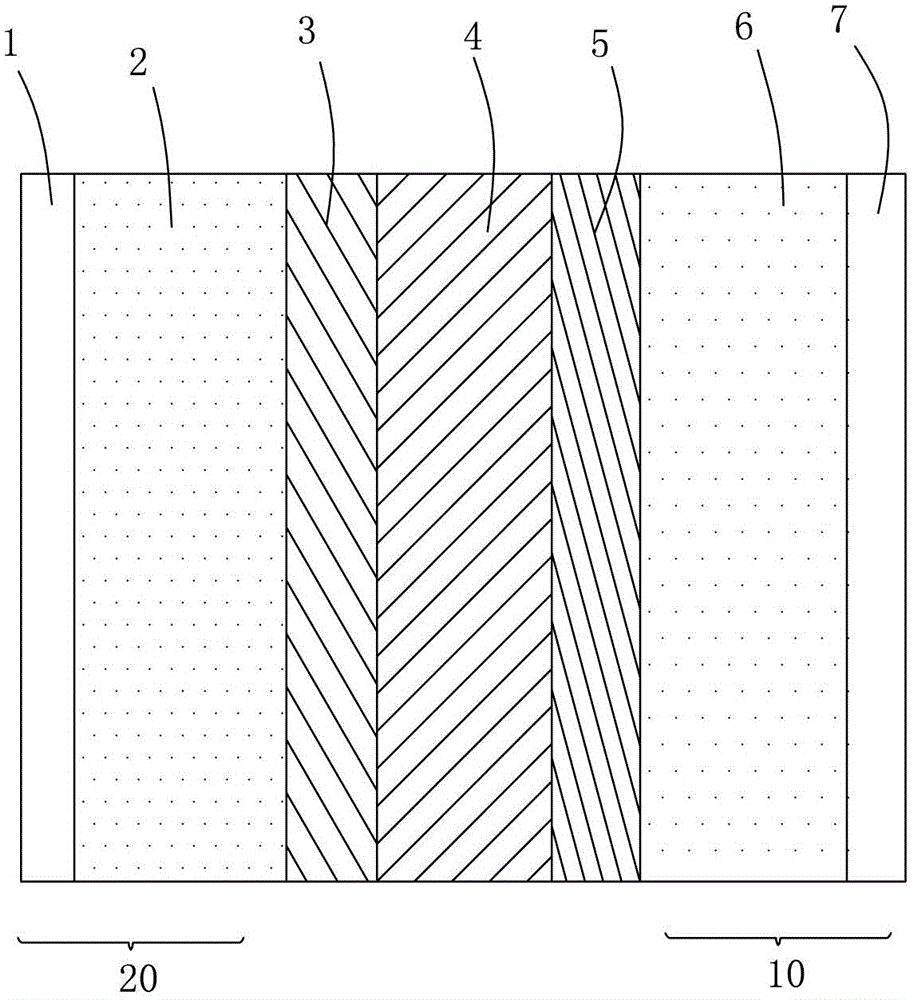

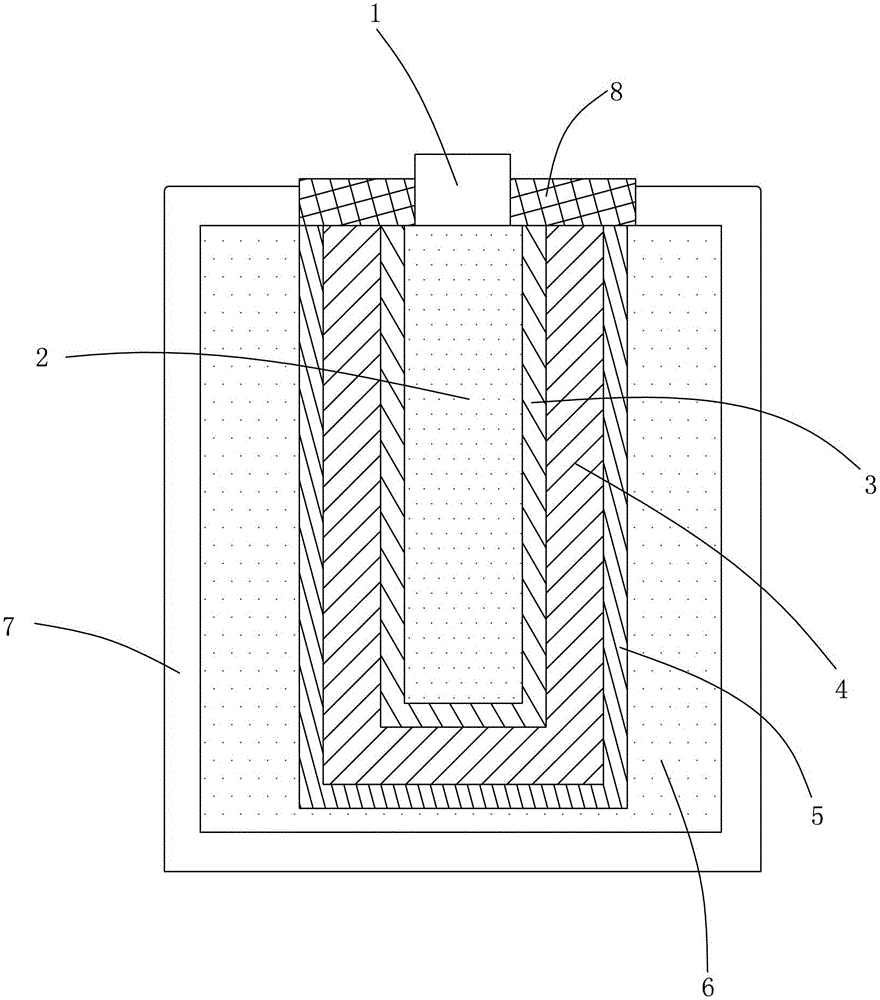

[0037] See attached figure 1 , the present invention provides a lithium-sulfur battery with high energy density and high cycle life. A lithium-sulfur battery includes a positive electrode, a negative electrode, a separator separating the positive and negative electrodes, and an electrolyte therein.

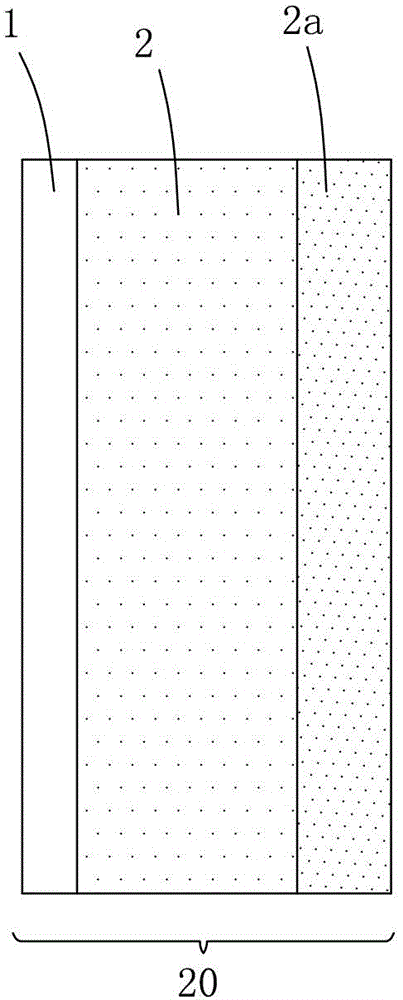

[0038] In this embodiment, the positive electrode of the lithium-sulfur battery, that is, the cathode 10 includes a cathode current collector 7 and a cathode active material 6 . The negative electrode of the lithium-sulfur battery, namely the anode 20 , includes an anode current collector 1 and an anode active material 2 . It can be seen from the drawings that a diaphragm 4 is provided between the cathode active material 6 and the anode active material 2 , and the anode electrolyte 3 and the cathode electrolyte 5 are separated by the diaphragm 4 . Thus, ions generated during charging and discharging of the battery can be transferred through the separator 4 , and the electrolyte ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com