Saltwater fish compound feed taking microalgae flour as fat source and processing method thereof

A technology of compound feed and microalgae powder, which is applied in animal feed, animal feed, application, etc., can solve the problems of lack, slow growth of fish body, and decreased immunity, so as to reduce the loss of nutrients, improve nutritional value, and promote The effect of fish body growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

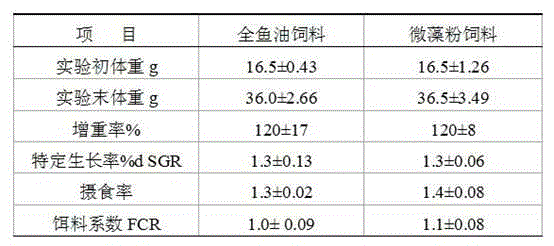

Examples

Embodiment 1

[0035] The seawater fish compound feed processed in this example is specially made for the early juveniles of seawater flounder fish, and two kinds of algae powders of Schizochytrium algae powder and Nannochloropsis algae powder are added as fat sources, specifically as follows The composition of raw materials in parts by weight: 40 parts of fish meal, 10 parts of casein, 4 parts of gluten, 13 parts of α-starch, 5.25 parts of microcrystalline cellulose, 0.5 part of thiobetaine, 9 parts of Schizochytridium algae powder, 13.5 parts of Nannochloropsis algae powder, 0.5 parts of sodium carboxymethylcellulose, 0.05 parts of antioxidant, 0.2 parts of choline chloride, 1.5 parts of multivitamins, and 1.5 parts of multivitamins.

[0036] The processing method of the present embodiment seawater fish compound feed comprises the following steps:

[0037] 1) First, cell wall breaking of the microalgae powder: the microalgae powder is vacuum freeze-dried at -50°C for 24 hours, and the drie...

Embodiment 2

[0046] The seawater fish compound feed of the present embodiment using microalgae powder as a fat source differs from Example 1 in that:

[0047] The compound feed consists of the following raw materials in parts by weight: 30 parts of fish meal, 11 parts of casein, 4 parts of soybean protein concentrate, 3 parts of gluten powder, 15 parts of α-starch, 6.5 parts of microcrystalline cellulose, and 0.8 part of thiobetaine , 6 parts of Schizochytrium algae powder, 10 parts of Nannochloropsis algae powder, 0.4 part of sodium carboxymethylcellulose, 0.03 part of antioxidant, 0.3 part of choline chloride, 1.0 part of multivitamin, 2.0 part of multivitamin .

[0048] The processing method of seawater fish compound feed in this embodiment, its step 3) is

[0049] 3) Pulverization: Mix the fishmeal, casein, soybean protein concentrate, gluten, α-starch, microcrystalline cellulose, and microalgae powder weighed in step 2) for the first time, and then coarsely pulverize them. Coarse cr...

Embodiment 3

[0051] The seawater fish compound feed of the present embodiment using microalgae powder as a fat source differs from Example 1 in that:

[0052] The compound feed consists of the following raw materials in parts by weight: 35 parts of fish meal, 8 parts of casein, 3 parts of soybean protein concentrate, 4.5 parts of gluten, 12 parts of α-starch, 8 parts of microcrystalline cellulose, and 0.6 part of thiobetaine , 8 parts of Schizochytrium algae powder, 8 parts of Nannochloropsis algae powder, 0.6 part of sodium carboxymethylcellulose, 0.02 part of antioxidant, 0.15 part of choline chloride, 0.8 part of multivitamin, 2.5 part of multivitamin .

[0053] The processing method of seawater fish compound feed in this embodiment, its step 3) is

[0054] 3) Pulverization: Mix the fishmeal, casein, soybean protein concentrate, gluten, α-starch, microcrystalline cellulose, and microalgae powder weighed in step 2) for the first time, and then coarsely pulverize them. Coarse crushing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com