Ceramic filtration plate cleaning method

A ceramic filter plate and post-filtration technology, which is applied in the direction of filtration separation, separation method, filter regeneration, etc., can solve the problems of reduced filtration efficiency, ceramic filter plate scrapping, inconvenience, etc., and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

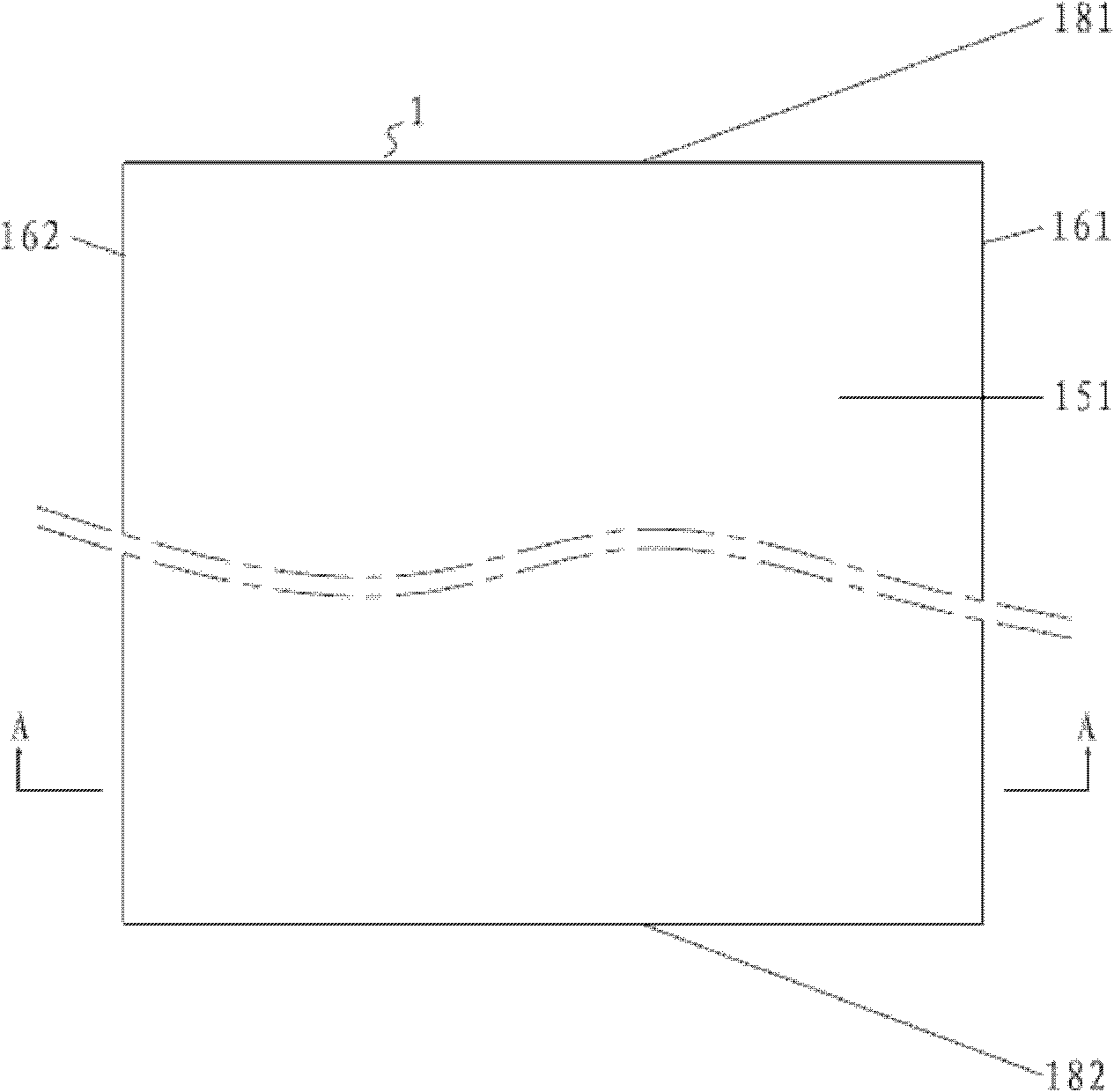

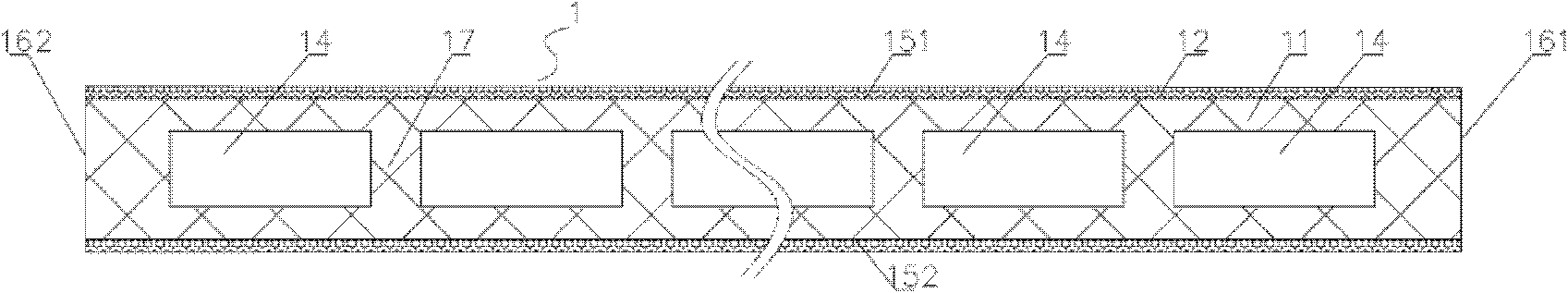

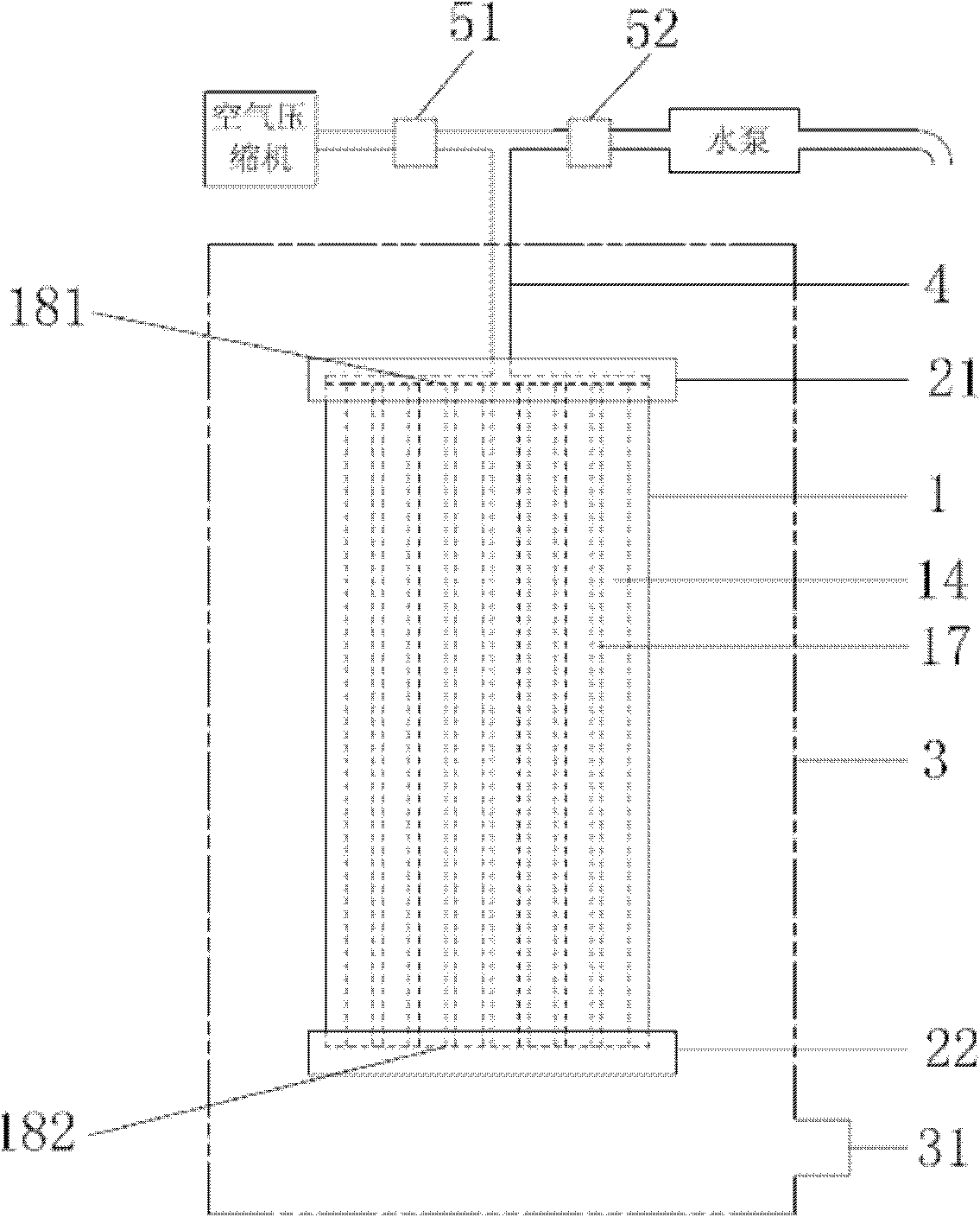

[0025] see figure 1 and figure 2 , the ceramic filter plate 1 described in this embodiment includes a ceramic substrate 11, and the ceramic substrate 11 includes two end surfaces 181 and 182, two side surfaces 161 and 162, and two mutually parallel bottom surfaces 151 and 152, and the ceramic The base plate 11 is provided with a cavity that runs through the two end faces 181 and 182 respectively. The cavity is used to store the filtered water. The cross-sectional shape of the cavity is a rectangle. The intersection lines of the plane and the bottom surface 151 (or 151) of the ceramic substrate are parallel to each other, and the ceramic substrate 11 is spray-coated with a nano-ceramic film 12 on the bottom surface, and the nano-ceramic film 12 is provided with irregular pores. The parallel bottom surfaces 151 and 152 can be curved surfaces, such as in a wavy shape. In this case, the overall shape of the ceramic substrate 11 is also wavy. The parallel bottom surfaces 151 and ...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the ceramic filter plate in this embodiment is a ceramic filter plate commonly used on an existing vacuum filter.

[0038] see Figure 4 , the ceramic filter plate 1' in this embodiment has a fan-shaped structure, and it has an installation hole 61 near the edge. The ceramic filter plate 1' includes a base body 63, and the outer surface of the base body 63 is coated with a filter coating. The base body 63 is provided with a cavity for storing filtered water, and the cavity forms water storage channels 62 distributed in the base body regularly or irregularly. There is also a drainage hole 64 on the top, one end of the drainage hole 64 is connected to the water collection channel 65, and the other end is connected to the air pipe 4 through the sealing joint 21', and the air pipe 4 is connected to the air compressor through the switch valve 51.

[0039] Based on the above structure, the ceramic filter plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com