Continuous production device for catalytic reaction by adopting phase transfer catalyst

A technology for phase transfer catalysts and production equipment, applied in chemistry/physics/physicochemistry fixed reactors, organic chemistry, etc., can solve problems such as limited application, difficulty in recycling catalysts, inability to achieve continuous production, etc., and shorten the process Process, overcoming the effect of intermittent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

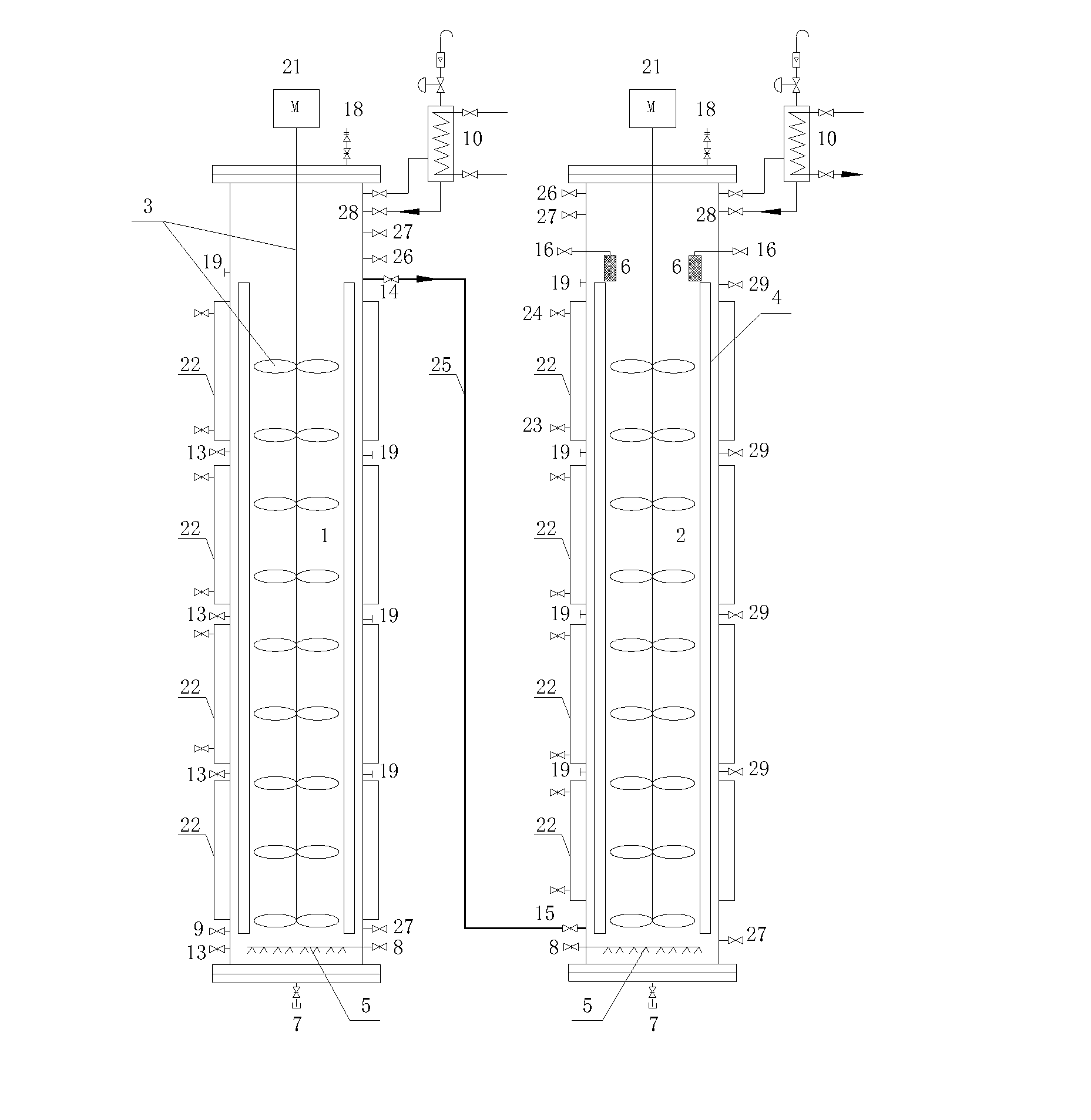

[0026] use figure 1 For the equipment shown, the height H of the cylinder of the first-stage reactor and the second-stage reactor is 3000mm, the diameter is 500mm, the height H of the baffle plate is 2400mm, the distance from the inner wall of the reactor cylinder is 100mm, and the number is 4 pieces. The gas distributor adopts the sintered metal tube filter element type, the diameter of the metal sintered filter element is 20mm, the pore size is 0.5μm, and the number is 4.

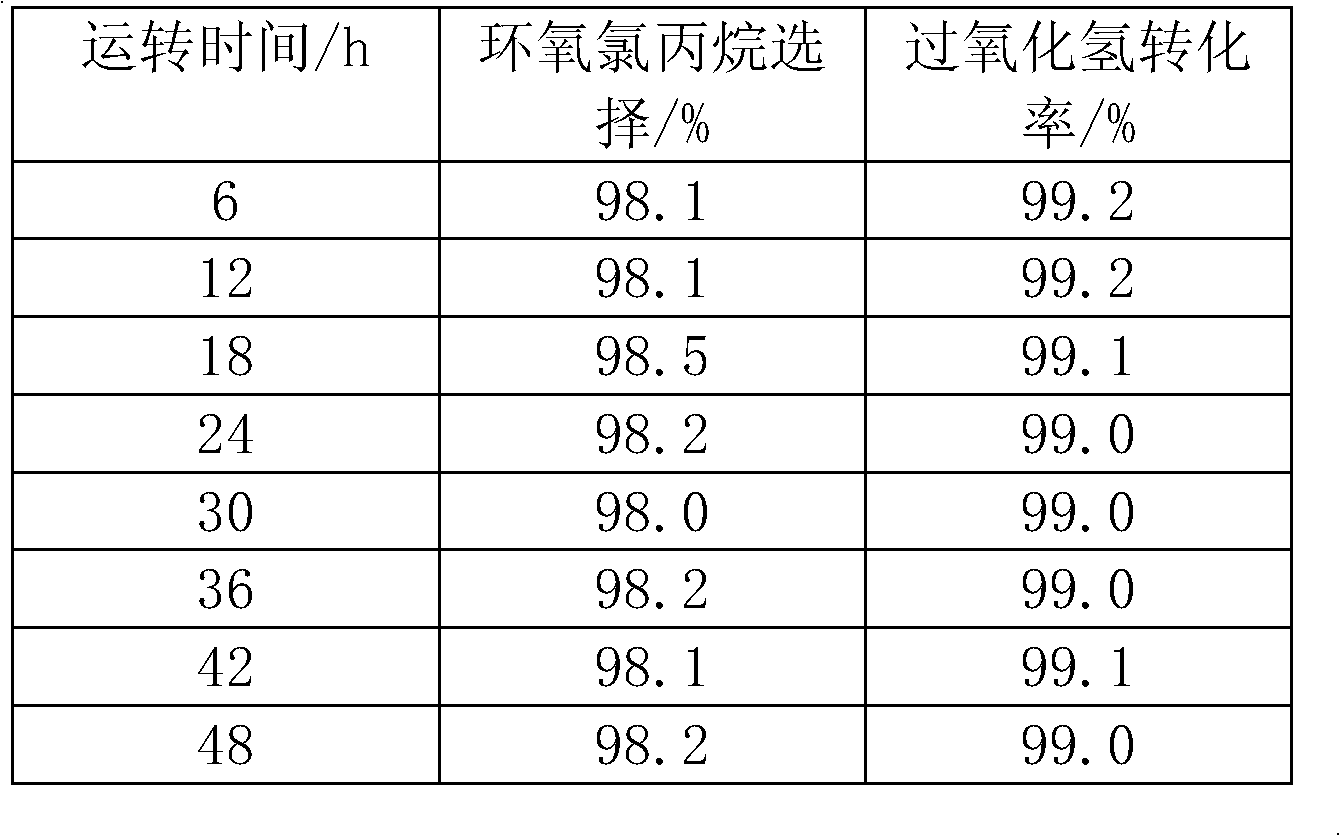

[0027] Direct oxidation of chloropropene to epichlorohydrin by reaction-controlled phase-transfer catalysis with hydrogen peroxide.

[0028] Hydrogen peroxide enters the reactor continuously from the three feed ports 13 in the upper part of the first-stage reactor 1, chloropropene enters the reactor continuously through the feed ports 13 in the lower part of the first-stage reactor 1, and nitrogen passes through the first-stage reactor 1 and the second-stage reactor The gas distributor 5 of 2 enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com