Radial gradient load three-way catalyst and preparation method

A three-way catalyst, radial gradient technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

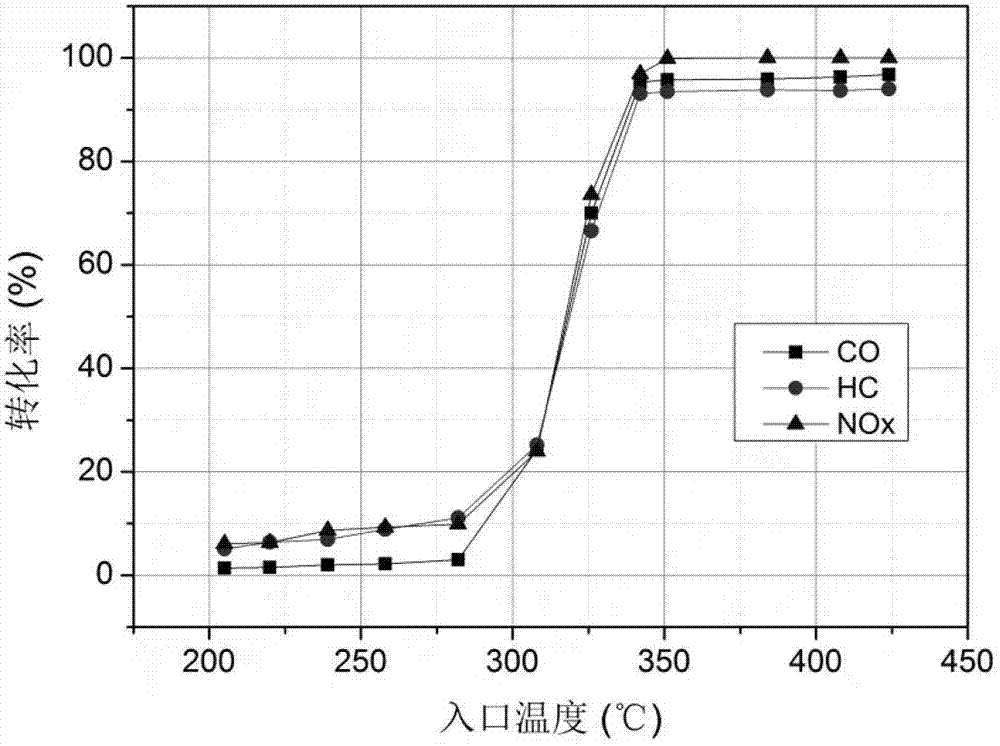

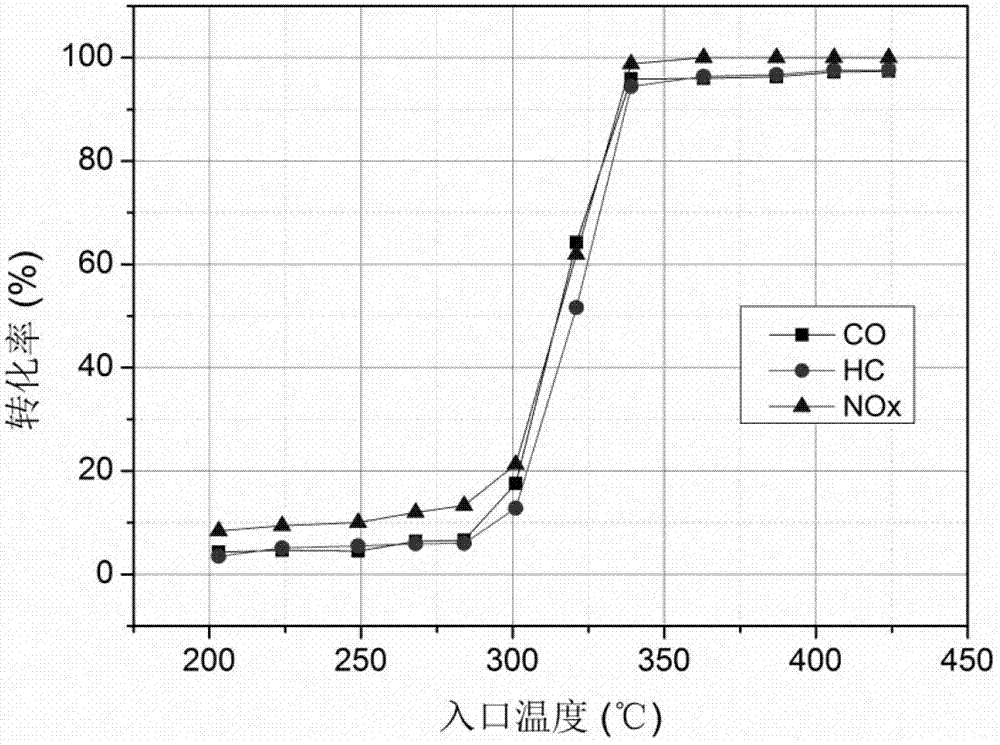

Embodiment 1

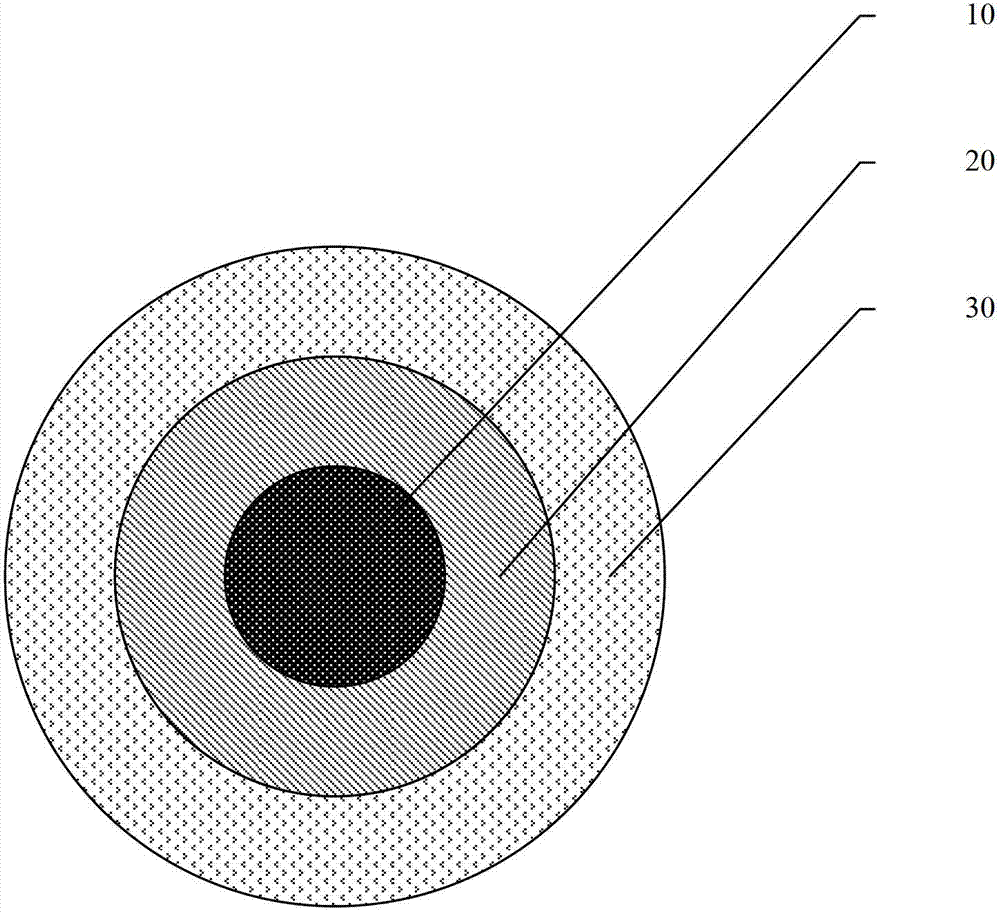

[0031] This example is used to illustrate the preparation of the catalyst of the present invention. Weigh 695g of cerium-zirconium-aluminum composite oxide (55wt%γ-Al 2 o 3 , 13wt%CeO 2 , 16wt%ZrO 2 , 3.5wt%BaO, 11wt%MgO, 1.5wt%Pr 6 o 11 , based on the mass of cerium-zirconium-aluminum composite oxide), 0.65g Rh(NO 3 ) 3 , 4.43g Pd(NO 3 ) 3 Mix with 1291g deionized water to make a mixture with a solid content of 35wt%, adjust the pH value to 3 with nitric acid, and wet ball mill for 4 hours to make a slurry. Add 7 g of polyvinyl alcohol solution and stir evenly, and use a catalyst radial gradient coating apparatus to load the slurry on the surface of the cylindrical cordierite honeycomb ceramic carrier in a radial gradient distribution. Taking the evenly loaded three-way catalyst loading as a benchmark, the coating material loading of the first zone 10 is the loading of the uniformly loading three-way catalyst (the loading of the coating material of the evenly loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com