Recovery method of carfentrazone-ethyl

A recovery method, the technology of carfentrazone-ethyl, which is applied in the new process field of recovery of high-purity carfentrazone-ethyl, can solve problems such as wasting products and energy consumption, product quality not meeting the requirements, unfavorable environment, etc., and achieves high recovery rate and easy operation Safe, simple and efficient process

Inactive Publication Date: 2013-06-19

JIANGSU BAOZONG & BAODA PHARMACHEM

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the low content of carfentrazone in the low boiling matter, usually only 30-50%, it cannot be applied directly, otherwise the quality of the product will not meet the requirements, so it is generally directly incinerated, which is a waste of product and energy. consumption, and not conducive to the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

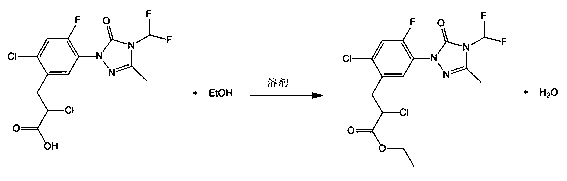

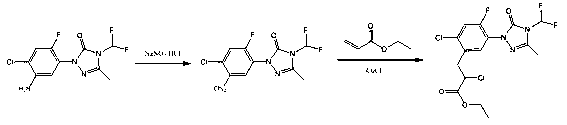

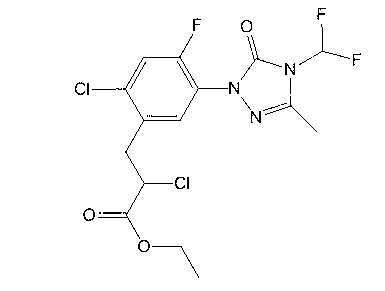

The invention discloses a recovery method of carfentrazone-ethyl. The recovery method is characterized in that the carfentrazone-ethyl in low-boiling wastes is hydrolyzed under an alkaline condition so that high-purity 2-chloro-3-[2-chloro-5-[4-(difluoromethyl)-4,5-dihydro-3-methyl-5-oxy-1H-1,2,4-triazole-1-yl]-4-fluorophenyl] propionic acid is obtained; and then the high-purity 2-chloro-3-[2-chloro-5-[4-(difluoromethyl)-4,5-dihydro-3-methyl-5-oxy-1H-1,2,4-triazole-1-yl]-4-fluorophenyl] propionic acid is esterified so that the carfentrazone-ethyl is obtained; the recovery rate reaches 92% and the content of the product is more than 96%. The new recover process provided by the invention is simple and efficient, safe for operation, high in recovery rate and suitable for industrial production.

Description

technical field [0001] The invention belongs to a recovery method of chemicals, in particular to a new process for recovery of high-purity carfentrazone-ethyl. Background technique [0002] Mefentrazone-ethyl, also known as mefentrazone-ethyl, triafentrazone-ethyl, the chemical name is (RS)-2-chloro-3-[2-chloro-5-(4-difluoromethyl-4,5-di Hydrogen-3-methyl-5-oxo-1H-1,2,4-triazol-1-yl)-4-fluorophenyl]propanoic acid ethyl ester, CAS No: 128639-02-1, was produced by FMC A high-efficiency and low-toxic triazolinone herbicide (WO9002120) developed by the company in 1988. Molecular formula: C 15 h 14 Cl 2 f 3 N 3 o 3 , relative molecular mass: 412.19, its chemical structure is as follows: The current industrial production of carfentrazone-ethyl generally adopts Meerwein arylation reaction, with acetonitrile or acetone as solvent, cuprous chloride as catalyst, sodium nitrite as diazotization reagent to 1-(5-amino-4-chloro -2-fluorophenyl)-4-(difluoromethyl)-3-methyl-1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D249/12

Inventor 朱志勇王琳陈荣

Owner JIANGSU BAOZONG & BAODA PHARMACHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com