Quick-drying red gouache and production method thereof

A gouache paint, quick-drying technology, applied in the direction of starch paint, art paint, natural rubber paint, etc., can solve problems such as difficult to render, faded picture, poor color retention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

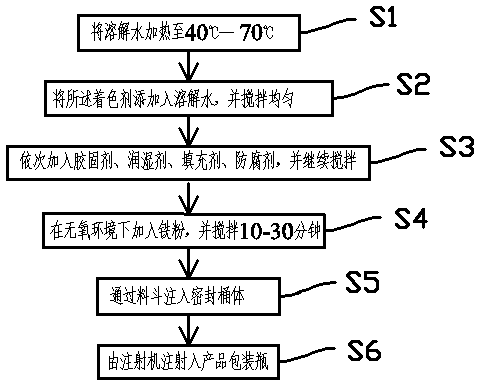

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0028] exist figure 1 In the shown embodiment, the following preparation steps of this quick-drying red gouache pigment are included: 1. Heating the dissolved water to 40°C-70°C S1;

[0029] 2. Add the coloring agent into the dissolved water, and stir evenly S2;

[0030] 3. Add cement, wetting agent, filler and preservative in sequence, and continue to stir S3;

[0031] 4. Add iron powder in an oxygen-free environment and stir for 10-30 minutes S4;

[0032] 5. Inject into the sealed barrel S5 through the hopper;

[0033] 6. Inject into the product packaging bottle S6 by the injection machine;

[0034] In steps S1-S6, the colorant is organic or inorganic pigment powder; the filler is white pigment or wheat starch; the cement is dextrin or gum; the wetting agent is rock sugar or glycerin; The preservative is carbolic acid or formalin.

[0035] And, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com