Production device, preparation method and use method of low-nitrogen carburant for clean steel refining

A technology of nitrogen recarburizer and production equipment, which is applied in the fields of carbon and iron and steel metallurgy, can solve the problems of limited sources, high price, and cannot meet the needs of high-quality low-nitrogen steel production, and achieves improved steel quality, low price, and calcination. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

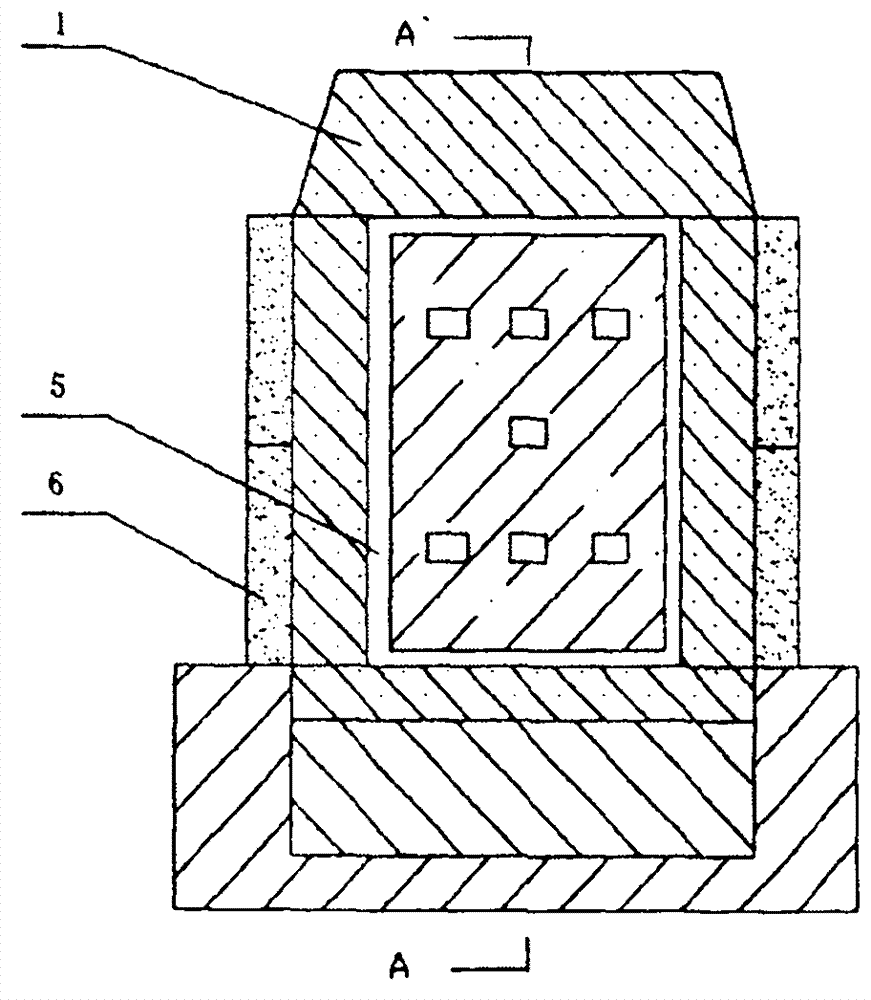

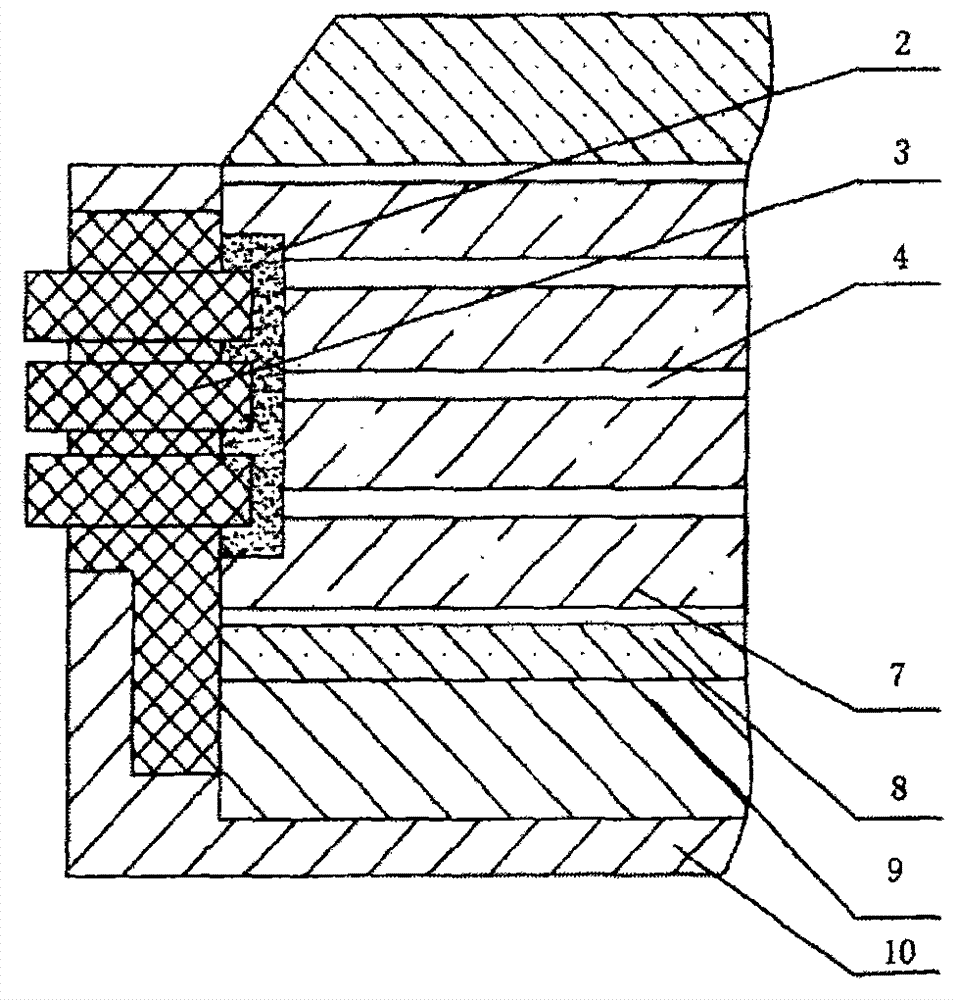

Image

Examples

example 1

[0035] Example 1 In order to reduce the nitrogen content of GCr15 bearing steel, when smelting bearing steel (GCr15) in a 60t converter, 10 heats were used to replace ordinary carburizers with low-nitrogen carburizers to increase the carburization of molten steel. The carbon in the steel was changed from the average 0.14% is increased to 0.88%, and 6.36 kg of low-nitrogen recarburizer needs to be added per ton of molten steel. The test results show that the nitrogen content in bearing steel can be reduced by 50ppm from the level of nearly 100ppm by using low-nitrogen carburizer.

example 2

[0037] Another test was carried out on a 100t converter. The smelting steel was No. 45 high-quality carbon structural steel. The test furnace was 12 furnaces. The amount of steel added per ton was 5kg. Reduce nitrogen content by 31ppm, a drop of 54%.

example 3

[0039] The third example test was carried out on a 100t converter, the smelting steel type was No. 75 hard wire steel, the test furnace was 8 furnaces, and the amount of steel added per ton was 7kg. Nitrogen levels dropped by 54% to the ideal level of 44ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com