Medical crepe paper body paper

A technology for paper base paper and crepe paper, applied in the field of special paper production, can solve the problems of high content of non-cellulose components, high tightness of medical crepe paper, poor elongation, etc., and achieves fine and soft texture and long service life. , the effect of good feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

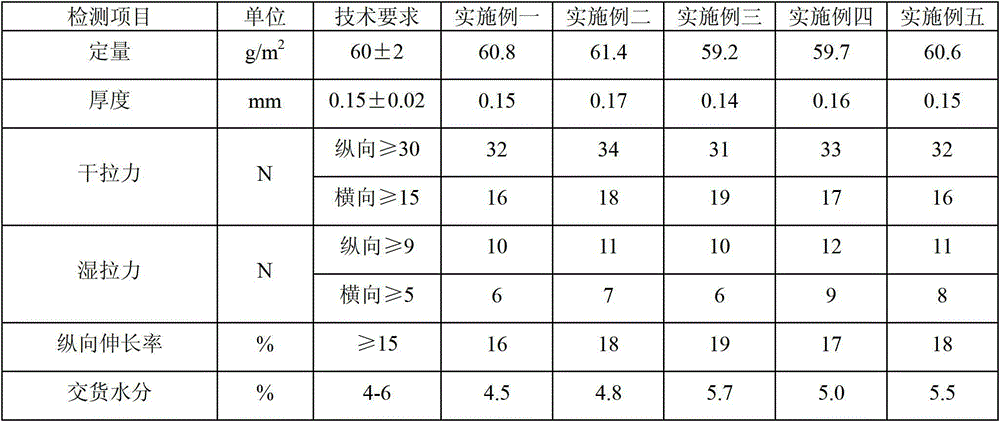

Examples

Embodiment 1

[0021] After pulping 60% of cotton pulp and 40% of coniferous wood pulp, mix and beat, so that the beating degree reaches 22°SR, and the wet weight is 10g; add PPE wet strength agent, the amount of wet strength agent accounts for 1.5% of the total pulp , after refining and homogenizing, use an inclined wire paper machine to make paper, and the concentration of the slurry on the net is 0.35%; then the wet scraper is wrinkled, and the angle between the wrinkling scraper and the tangent line of the cylinder surface is 30°, and the scraper is placed on the surface of the cylinder The blade angle is 75°; it is dried in a drying cylinder, and then cut and packaged to obtain the finished medical crepe paper base paper.

Embodiment 2

[0023] After pulping 55% of cotton pulp and 45% of coniferous wood pulp, mix and beat, so that the degree of beating reaches 23°SR, and the wet weight is 11g; add PPE wet strength agent, the amount of wet strength agent accounts for 1.8% of the total pulp , after refining and homogenizing, use an inclined wire paper machine to make paper, and the concentration of the slurry on the net is 0.35%; then the wet scraper is wrinkled, and the angle between the wrinkling scraper and the tangent line of the cylinder surface is 32°, and the scraper is placed on the surface of the cylinder The blade angle is 80°; it is dried in a drying cylinder, then cut and packaged to obtain the finished medical crepe paper base paper.

Embodiment 3

[0025] After pulping 50% of cotton pulp and 50% of coniferous wood pulp, mix and beat, so that the degree of beating reaches 24°SR, and the wet weight is 12g; add PPE wet strength agent, the amount of wet strength agent accounts for 2% of the total amount of pulp , after refining and homogenizing, use an inclined wire paper machine to make paper, and the concentration of the slurry on the net is 0.35%; then the wet scraper is wrinkled, and the angle between the wrinkling scraper and the tangent line of the cylinder surface is 35°, and the scraper is placed on the surface of the cylinder The blade angle is 78°; it is dried in a drying cylinder, and then cut and packaged to obtain the finished medical crepe paper base paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com