Well and rock salt solution mining-well recharging filling circulation mining method

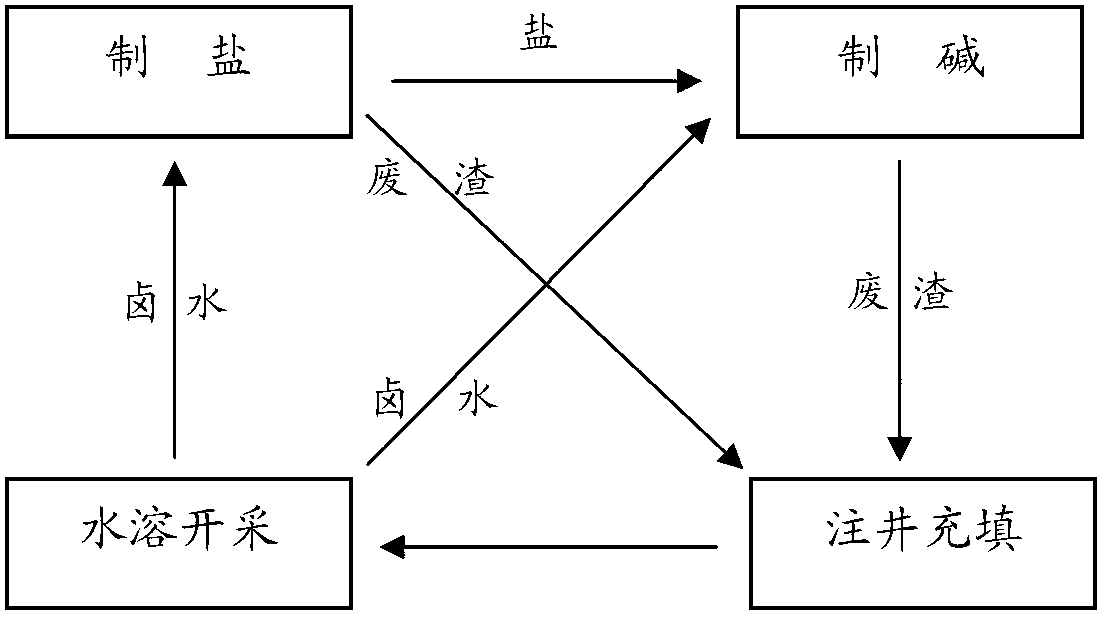

A mining method and mine salt technology, which can be applied to filling materials, ground mining, mining equipment, etc., can solve the problems of easily induced ground subsidence, low recovery rate of well mine salt resources, and environmental pollution by waste slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

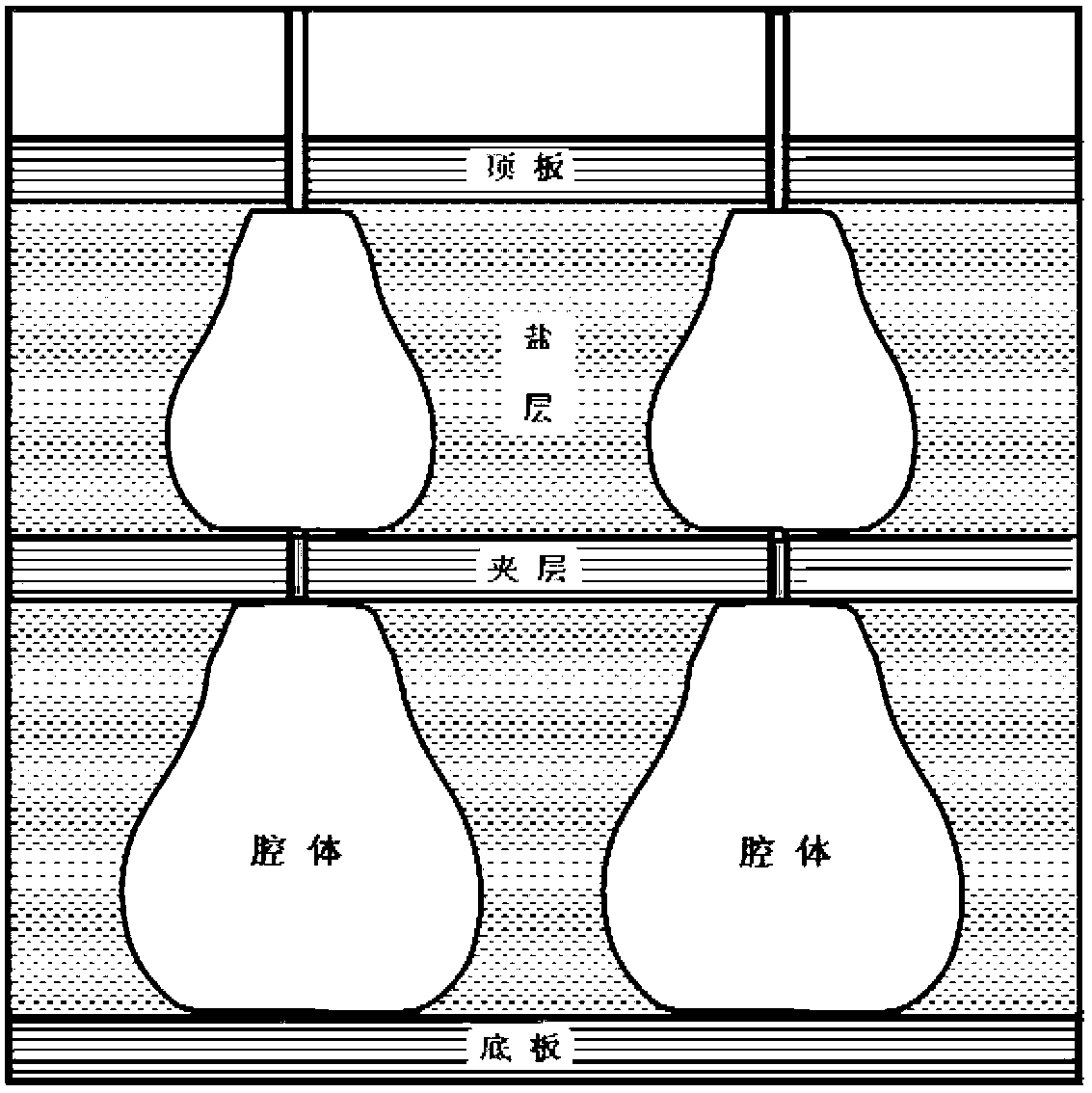

[0073] Such as figure 2 As shown, for ultra-thick salt deposits (the burial depth is -900 ~ -1450m, the total thickness is about 550m), the single well oil pad method water solution mining-injection well filling cycle mining method is adopted, which is realized through the following steps:

[0074] (1) Drill a single well on the surface to the target ore deposit, and lower the brine mining pipe string of the salt well to about -1450m. The oil cushion method is used for water solution mining, and the brine is used as raw material for salt or alkali production.

[0075] (2) After a period of water-soluble mining, after reaching the maximum allowable amount of mined salt, combine the sonar cavity measurement technology to measure the solution diameter and shape of the cavity, and determine the volume of the cavity.

[0076] (3) The waste slag generated in the process of alkali making, salt making or coal burning is filled into the salt mining solution cavity through the brine m...

Embodiment 2

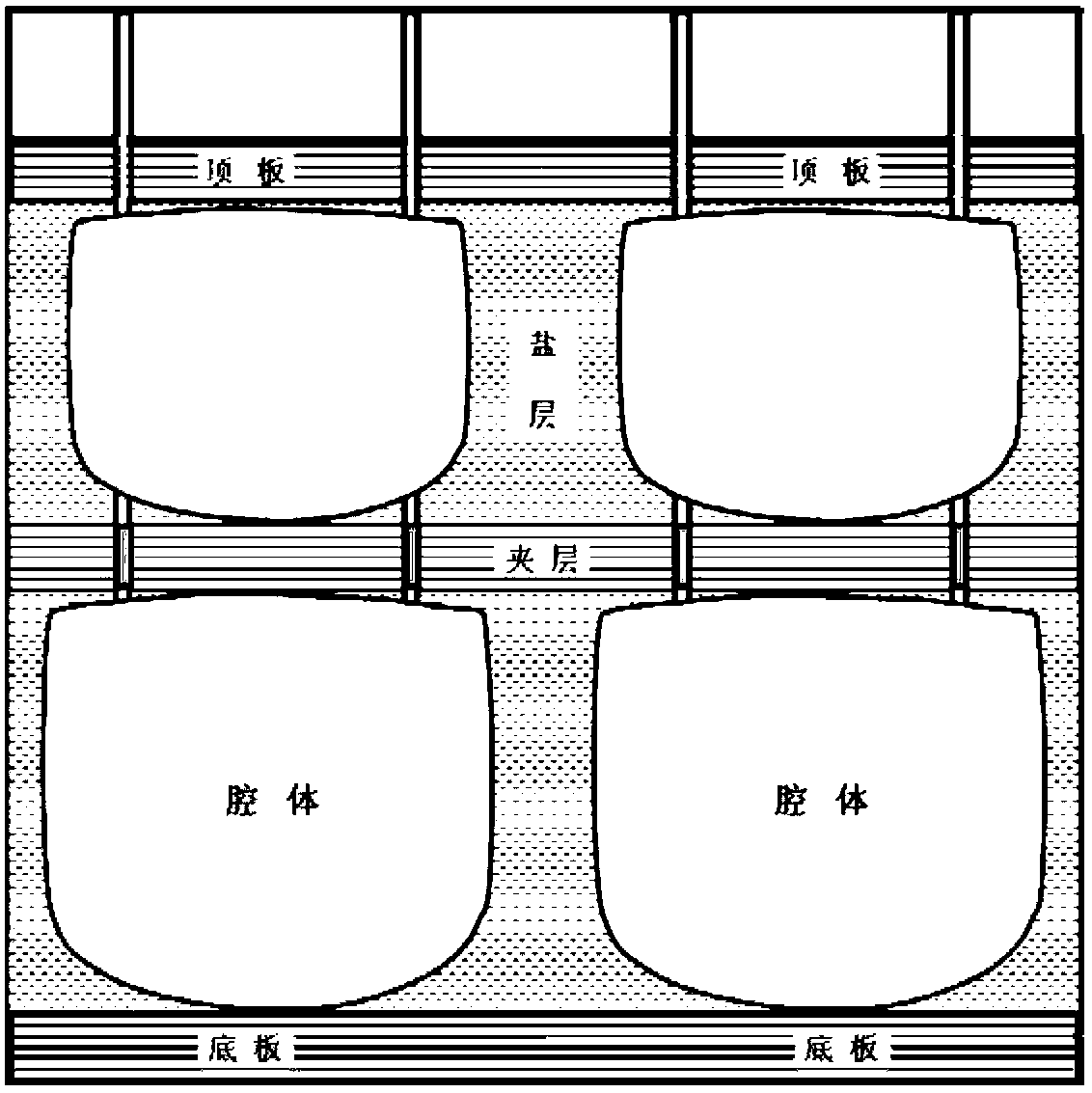

[0083] Such as image 3 As shown, for ultra-thick salt deposits (the burial depth is -1000 ~ -1530m, the total thickness is about 530m), the two-well directional connected convective water solution mining-injection well filling cycle mining method is adopted, which is realized through the following steps:

[0084] (1) Using directional connection technology to build two butt joint wells for water-soluble mining of the lower salt group (thickness is about 300m, depth is -1230~-1530m), and the mined brine is used as raw material for salt or alkali production.

[0085] (2) After a period of double-well convective water solution mining, after reaching the maximum allowable salt production, combine the sonar cavity measurement technology to measure the solution diameter and shape of the cavity, and determine the volume of the cavity.

[0086] (3) Inject the waste slag produced in the process of alkali production, salt production or coal combustion into the salt mining solution cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com