Fluorescent lampshade type light-emitting diode (LED) white light module

A fluorescent lamp and module technology, applied in the field of fluorescent lampshade type LED white light modules, can solve the problems of poor effect, high cost, complicated design and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

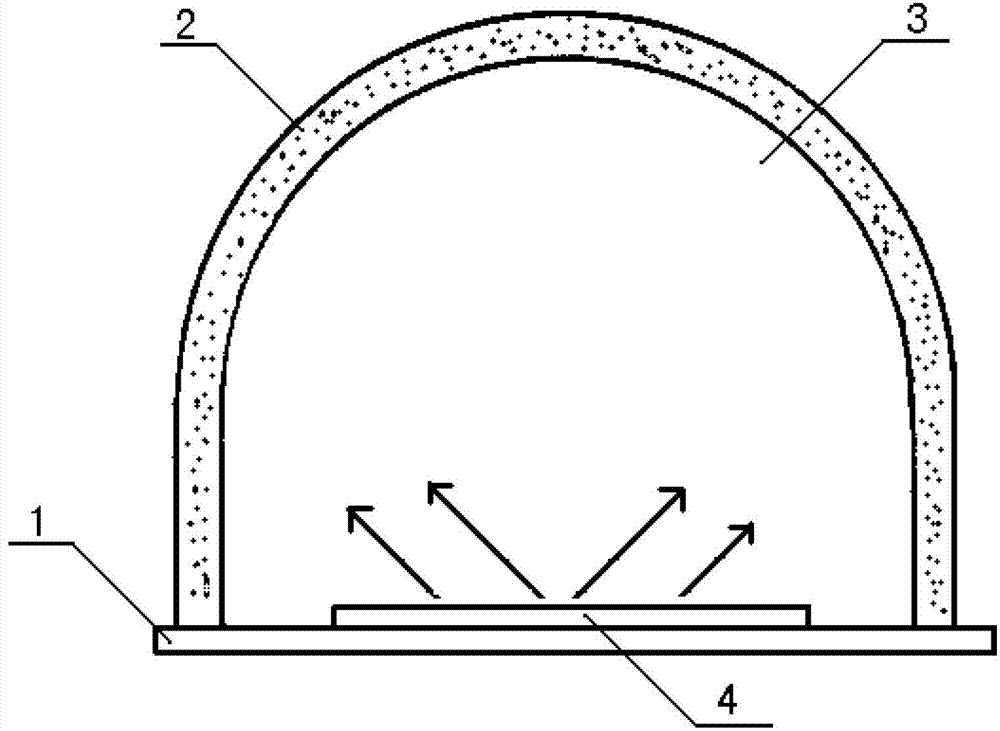

[0049] 1. Use 100 parts by weight of liquid transparent epoxy resin or silica gel as the base material, then add 0.3-10 parts by weight of yellow fluorescent powder for LEDs in proportion, mix thoroughly, and then use ordinary casting method or pressurized gelation molding The technology injects the liquid mixture into the lampshade mold, and depending on the solidification characteristics of the base material, a qualified solid LED lampshade containing uniformly distributed phosphors can be obtained after a few minutes to a few hours.

[0050] 2. Then pour a transparent layer (silica gel or epoxy) inside the solid LED lampshade containing phosphor, and after the transparent layer is cured, the lampshade of the large-angle module is obtained.

[0051] 3. Put the lampshade on the blue LED light-emitting tube (or light-emitting assembly) to fix it, and you can get a large-angle LED module.

Embodiment 2

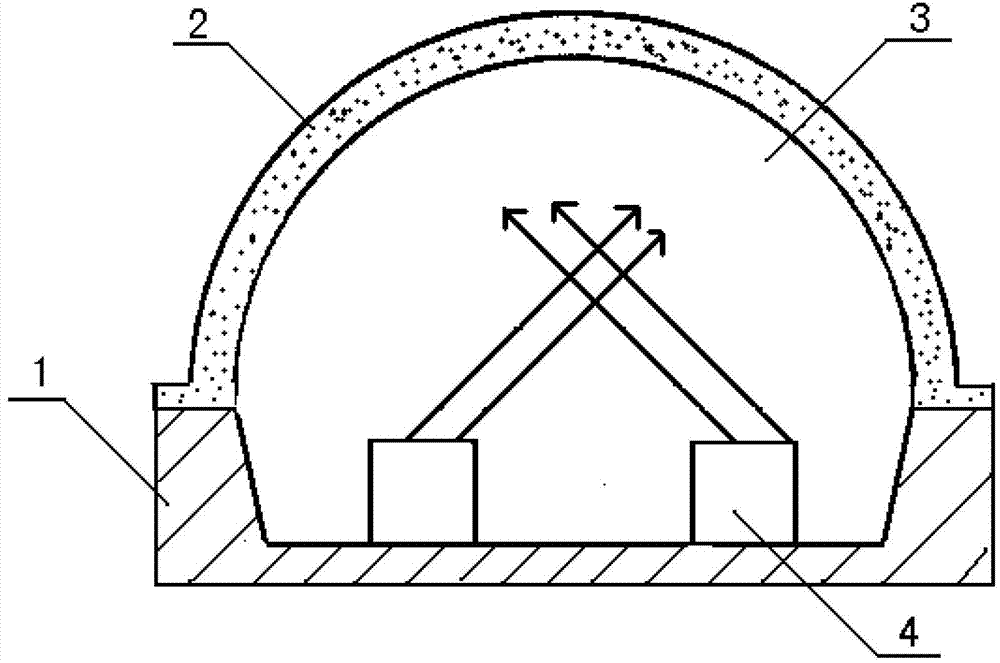

[0053] 1. It is also possible to use transparent materials such as plastics and PCs mixed with phosphor powder at a ratio of less than 15%, and obtain solid LED masks containing phosphor powder by injection molding and other methods.

[0054] 2. Then pour a transparent layer (silica gel or epoxy) inside the solid LED lampshade containing phosphor, and after the transparent layer is cured, the lampshade of the large-angle module is obtained.

[0055] 3. Put the lampshade on the blue LED light-emitting tube (or light-emitting assembly) and fix it to get a large-angle LED module

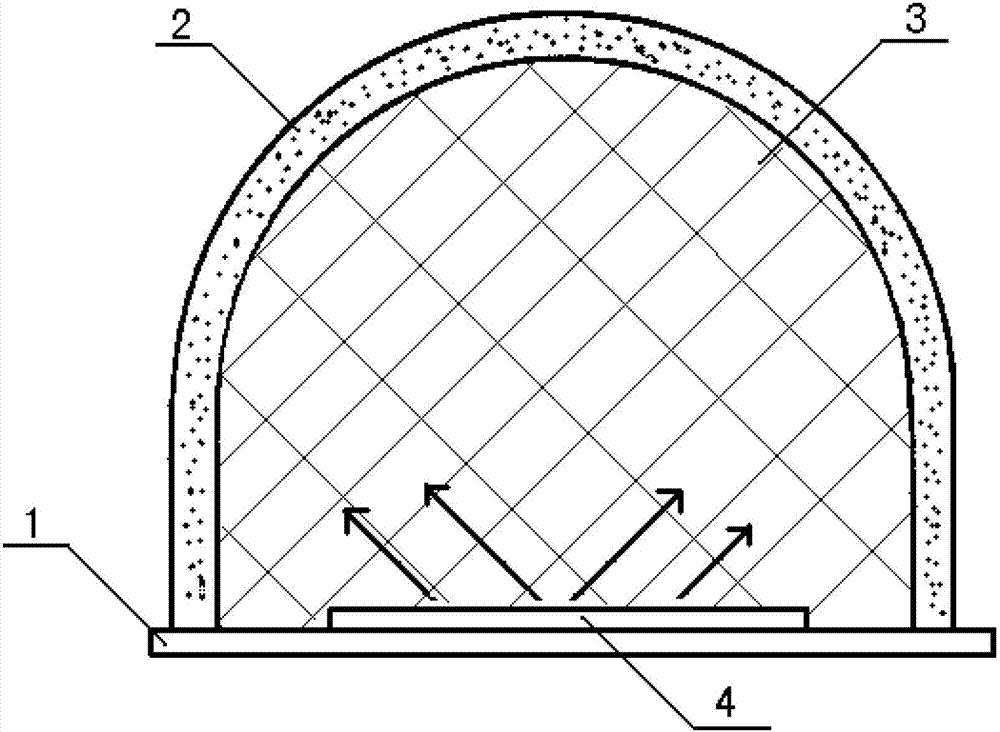

[0056] For the fluorescent lampshade type LED white light module proposed by the above technical solution, if liquid state epoxy resin and silica gel are used as the base material of the lampshade, and a certain amount of phosphor powder is added to the base material to make the lampshade, the molding is not only simple. Moreover, since the base material is liquid, the powdery fluorescent powder can be qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com