High-power-density high-efficiency permanent magnet synchronous motor used for vehicle

A permanent magnet synchronous motor, high power density technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the eddy current loss of permanent magnet materials High, high motor operating frequency, low efficiency and other problems, to achieve the effect of reducing motor torque ripple, strong stator harmonic current capability, and reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Referring to the accompanying drawings, the present invention will be further described.

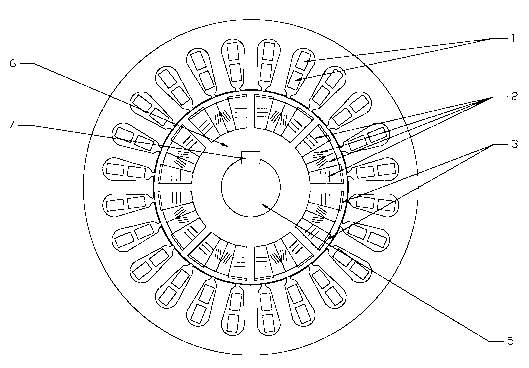

[0017] Such as figure 1 As shown, the present invention provides a permanent magnet synchronous motor with a Halbach array and a copper ring rotor structure for an electric vehicle. Stator winding 1, stator core 4, copper ring 3, NdFeB permanent magnet 2, rotor core 6, flat key 7, rotor core 6 is made of laminated silicon steel sheets, and rotor core 6 is fixed on the On the rotating shaft 1, a rotary transformer 11 is installed at the non-output shaft extension end of the rotor. The stator form of this motor is the same as that of a traditional permanent magnet synchronous motor, and its permanent magnet rotor includes a rotating shaft 5, a NdFeB permanent magnet 2, a copper sheet 3 and a rotor core 6. The permanent magnet 2 under each pole of the rotor is placed in the form of a four-section Halbach array. The two sections on the edge of each pole are magnetized tangentially, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com