Magnetic iron powder composition and preparation method thereof, magnetic core and inductor

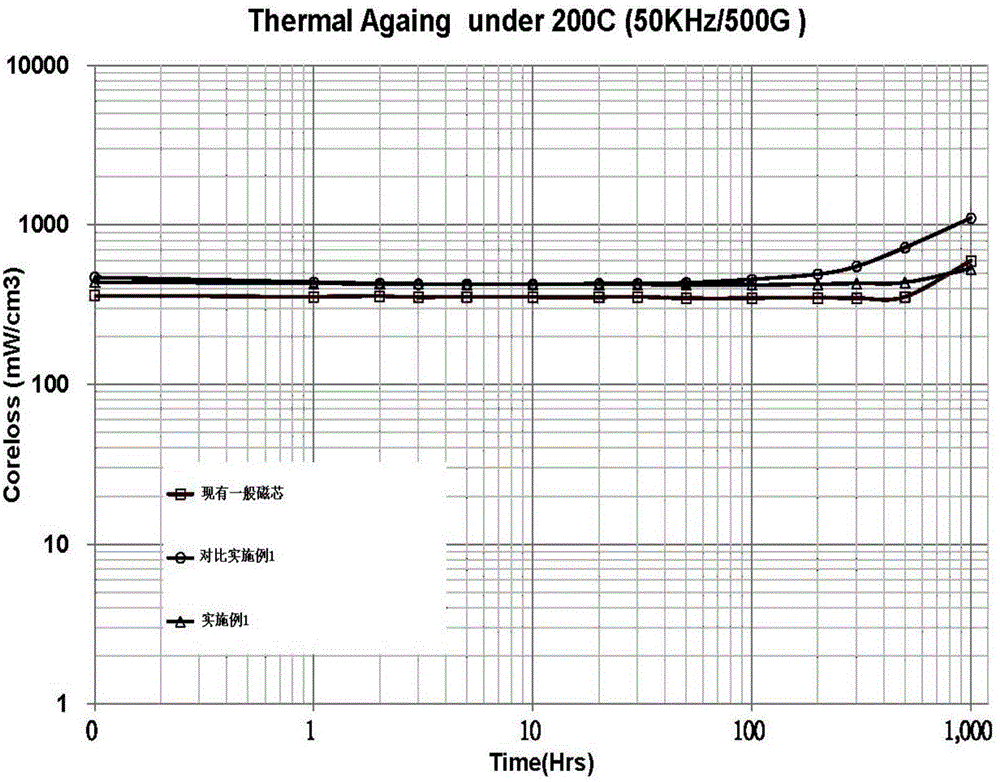

A technology of magnetic iron and composition, applied in the direction of magnetic objects, magnetic materials, magnetic core/yoke, etc., can solve the problems of fast aging speed, increased core loss and temperature rise, and poor insulation properties, etc., to achieve anti-aging Effects of core loss, improvement of insulation characteristics, and reduction of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The magnetic iron powder composition of the present embodiment 1 comprises: reduced iron powder, iron phosphate film formed on the surface of reduced iron powder and phenolic resin coated on iron phosphate; wherein: iron phosphate accounts for the mass percent of reduced iron powder is 0.15%; the mass percentage of phenolic resin in the reduced iron powder is 1%.

[0042] The preparation method of the magnetic iron powder composition of the present embodiment 1 is as follows:

[0043] (a) First, add 1g of phosphoric acid and 1g of phosphoric acid accelerator into 40g of alcohol and stir evenly, add the solution into 1Kg of reduced iron powder (Fe>99%) and stir for 15 minutes, then bake and stir at 130°C for 120 minutes to obtain powder material.

[0044] (b) Add 10g of phenolic resin to 60g of alcohol and stir evenly, add the solution to the powder prepared in the previous step and stir for 10 minutes, pass through a 24-mesh sieve when the powder is half dry, and bake ...

Embodiment 2

[0052] This embodiment 2 provides a magnetic iron powder composition, which includes: carbonyl iron powder, an iron phosphate film formed on the surface of the carbonyl iron powder, and a phenolic resin coated on the iron phosphate; wherein: iron phosphate accounts for the carbonyl iron powder The mass percentage is 4.6%; the mass percentage of the phenolic resin in the carbonyl iron powder is 4%.

[0053] The preparation method of the magnetic iron powder composition of present embodiment 2 is as follows:

[0054] (a) Add 30g of phosphoric acid and 1g of phosphoric acid accelerator to 40g of alcohol and stir evenly, then add the solution to 1Kg of carbonyl iron powder and stir for 15 minutes, then bake and stir at 130°C for 120 minutes to obtain powder.

[0055] (b) Add 40g of phenolic resin to 60g of alcohol and stir evenly, add the solution to the powder prepared in the previous step and stir for 10 minutes, pass through a 24-mesh sieve when the powder is half dry, and bake...

Embodiment 3

[0063] This embodiment 3 provides a magnetic iron powder composition, which includes: carbonyl iron powder, an iron phosphate film formed on the surface of the carbonyl iron powder, and a phenolic resin coated on the iron phosphate; wherein: iron phosphate accounts for the carbonyl iron powder The mass percentage is 0.46%; the mass percentage of the phenolic resin in the carbonyl iron powder is 3%.

[0064] The preparation method of the magnetic iron powder composition of present embodiment 3 is as follows:

[0065] (a) First, add 3 g of phosphoric acid and 1 g of phosphoric acid accelerator into 40 g of alcohol and stir evenly, then add the solution into 1 kg of carbonyl iron powder and stir for 15 minutes, then bake and stir at 130° C. for 120 minutes to obtain powder.

[0066] (b) Add 30g of phenolic resin to 60g of alcohol and stir evenly, add the solution to the powder prepared in the previous step and stir for 10 minutes, pass through a 24-mesh sieve when the powder is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com