Light-emitting diode (LED) double-sided circuit board made by four wires

A circuit board, double-sided technology, applied in the direction of printed circuits and printed circuit components connected with non-printed electrical components, can solve the problems of high heat generation, high copper foil cost, high material cost, etc., and achieve practical work. The effect of life improvement, working length extension, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

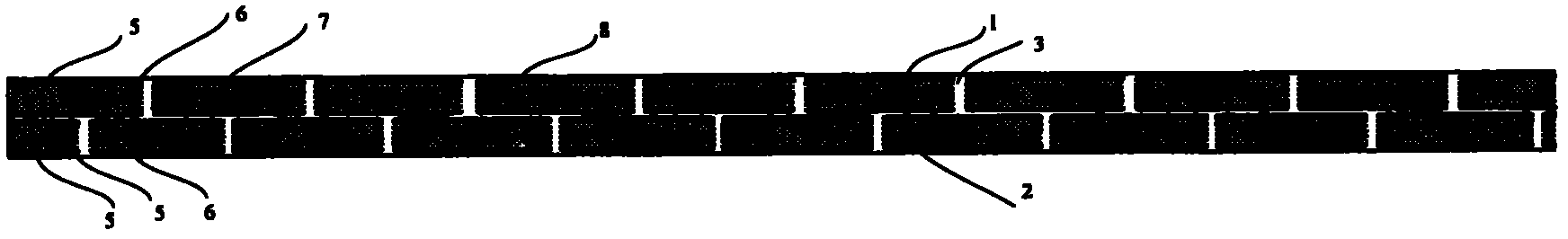

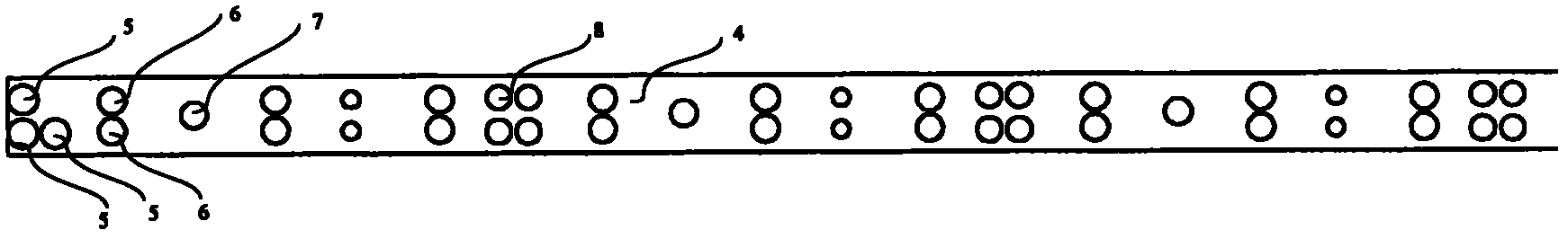

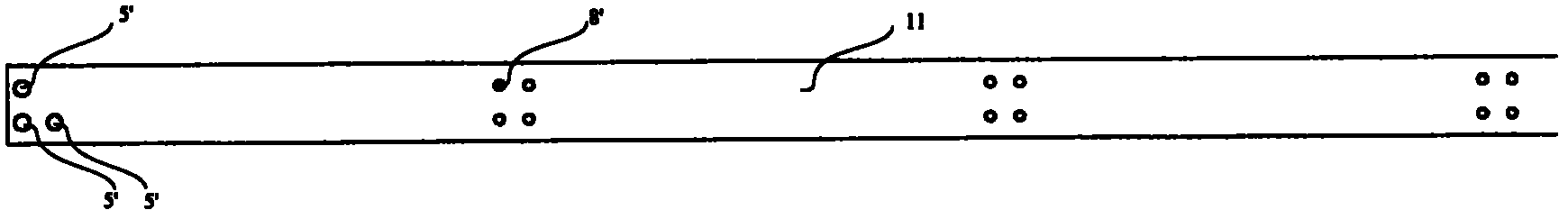

[0050] The term "double-sided wiring board" means that the wiring is provided on both sides of the wiring board.

[0051] Before describing the present invention in detail, it should be understood by those skilled in the art that "element" should be understood in this application in the broadest sense, i.e., to include all types of electronic components, electrical components or other types of components used in circuits, For example, various resistors, various surface mount (SMT) type components, bracket type components, various high-power devices, etc., including high-power LEDs, and so on.

[0052] Furthermore, the terms "circuit board" and "circuit board" are used interchangeably in this application.

[0053] The manufacturing process and structure of the LED circuit board of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0054] Related materials of LED circuit board

[0055] The raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com