Preparation method of in-situ repair material for soil polluted by heavy metal chromium and application of material

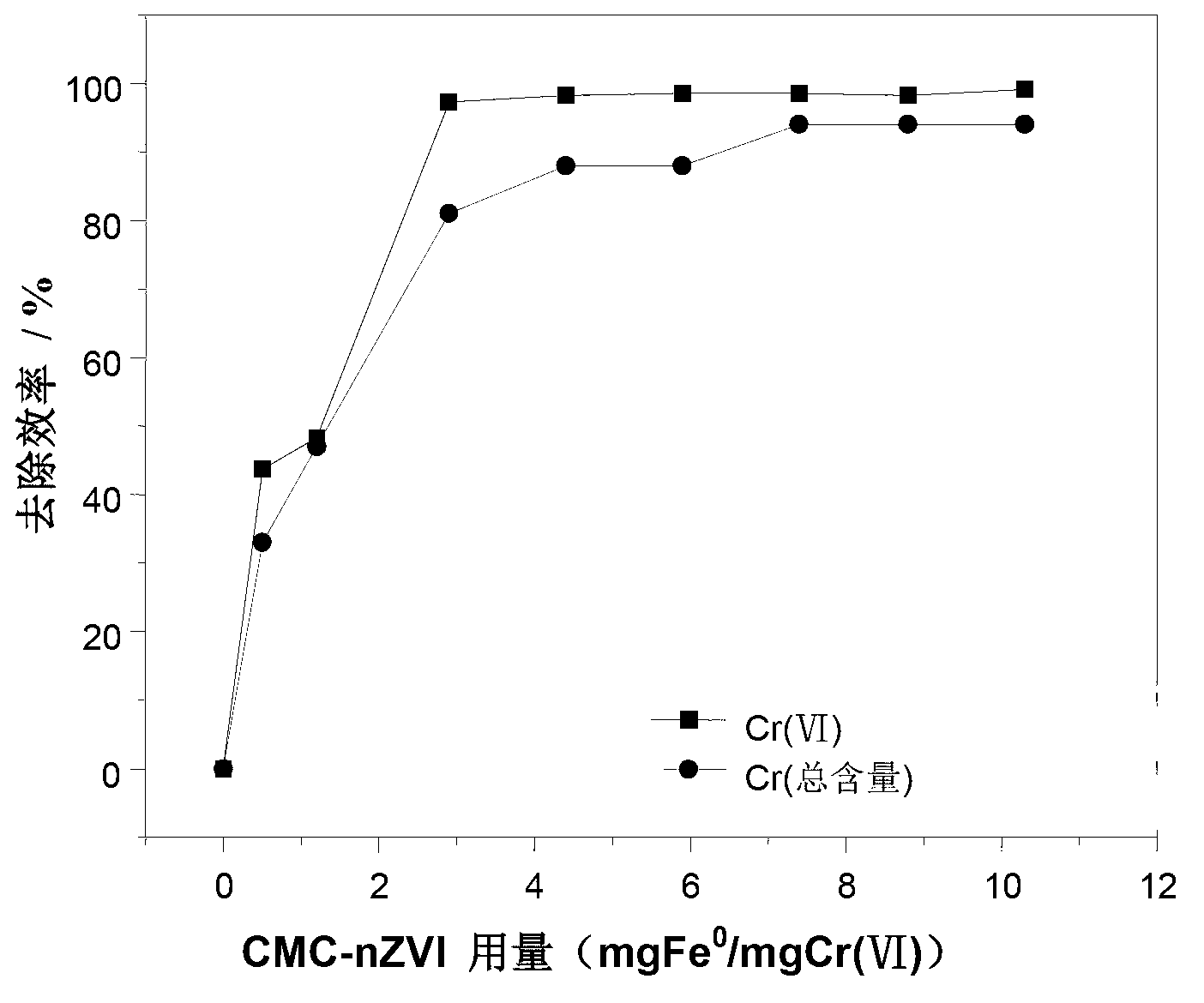

An in-situ remediation and soil technology, applied in the restoration of contaminated soil, etc., can solve the problems of easy aggregation of nano-metal particles, low processing efficiency, and poor fluidity, and achieve good fluidity, low preparation cost, and difficult aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a modified nano metal particle suspension, comprising the steps of:

[0034] 1) Dissolve carboxymethyl cellulose in water and carry out oxygen removal treatment, then add steel pickling waste liquid and stir for 5-30 minutes to obtain solution A;

[0035] 2) Dissolve the reducing agent in 15-50% ethanol solution (mass ratio of ethanol to water) to obtain solution B;

[0036] 3) Add solution B dropwise to solution A while stirring, and continue to stir until the solution turns black. After ultrasonic treatment for 5-30 minutes, solution C is obtained, which is a modified nano-metal particle suspension containing zero-valent iron.

Embodiment 1

[0051] The preparation method of the CMC-nZVI of different stability comprises the steps:

[0052] 1) Dissolve 1.2g of carboxymethylcellulose (CMC) in 900mL of deionized water, stir until completely dissolved, blow with nitrogen for 15 minutes to remove dissolved oxygen in the solution, add 20mL of steel pickling waste, and stir at 30rpm 5min, obtain solution A;

[0053] 2) Dissolve 13g of sodium borohydride in 280mL of 30% (w / w) ethanol solution to obtain solution B;

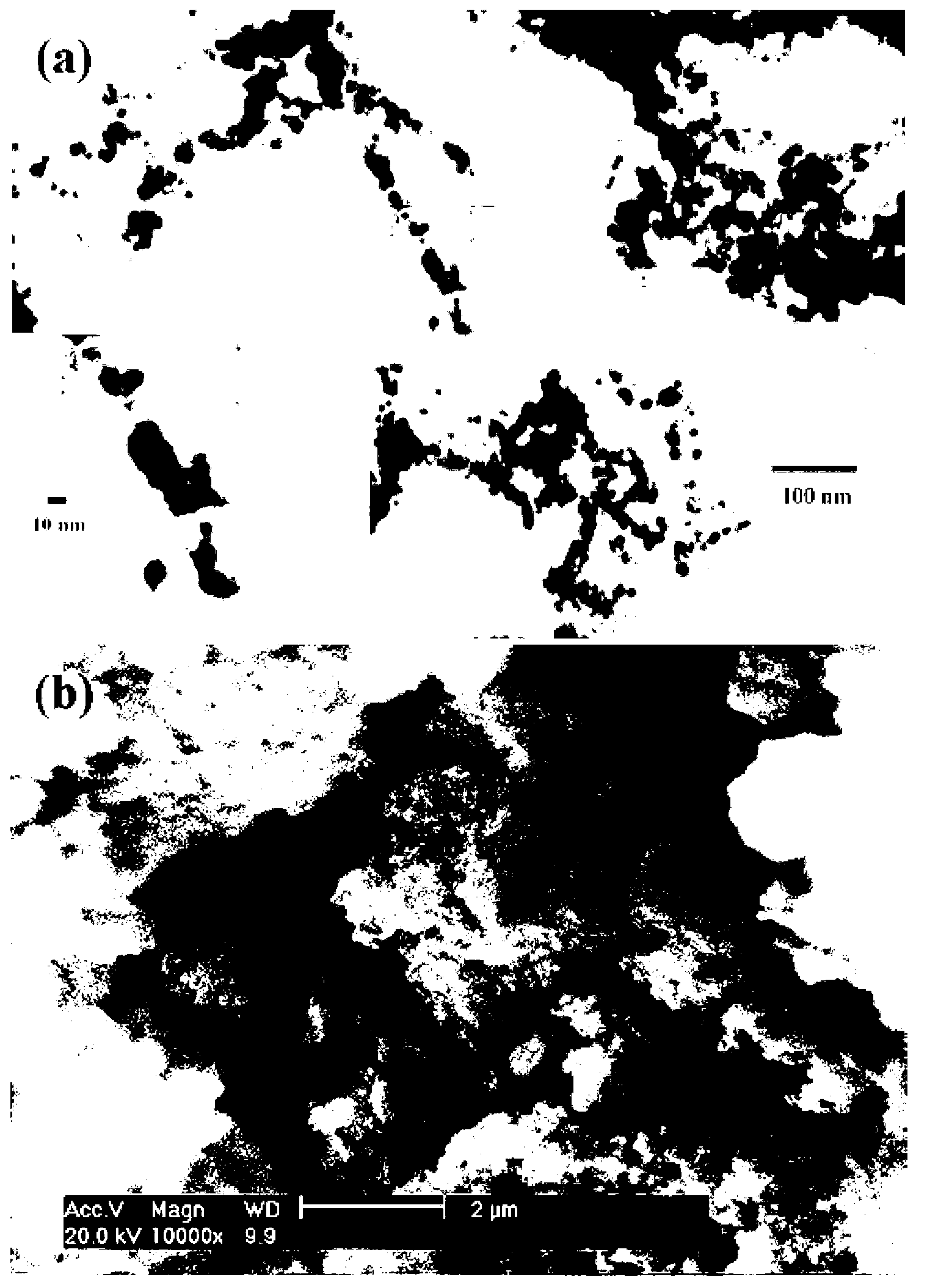

[0054] 3) Slowly add solution B dropwise to solution A under stirring, continue to stir until the solution turns black, undergo ultrasonic treatment with a frequency of 30 Hz for 15 minutes, and let stand for 20 minutes to obtain solution C, which contains zero-valent iron (Fe 0 ) modified nano-metal particle suspension (suspension 1) modified with 0.1% CMC (w / w) at a concentration of 0.2 g / L, represented by CMC-nZVI.

[0055] 4) Prepare Fe separately 0 CMC-nZVI modified with 0.2 and 0.3% CMC at a concentrat...

Embodiment 2

[0058] Different Fe 0 The preparation method of the CMC-nZVI of concentration, comprises the steps:

[0059] 1) Dissolve 0.2g of carboxymethyl cellulose in 80ml of deionized water, stir until completely dissolved, blow with nitrogen for 10min, add 0.1mL of 10-fold diluted iron and steel pickling waste, and stir at 25rpm for 20min to obtain solution A;

[0060] 2) Dissolve 3mg of sodium borohydride in 39.9mL of 30% (w / w) ethanol solution to obtain solution B;

[0061] 3) Slowly add solution B dropwise to solution A under stirring, continue to stir until the solution turns black, undergo ultrasonic treatment with a frequency of 45Hz for 5min, and let it stand for 15min to obtain Fe 0 The appearance of CMC-nZVI modified by 0.17% CMC (suspension 4) with a concentration of 0.01 g / L is similar to that of the product obtained in Example 1.

[0062] According to the above method, Fe 0 For 0.17% CMC-modified CMC-nZVI (suspension 5-8) with a concentration of 0.01-0.21g / L, the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com