Device and method for automatically eliminating shortage of lap joint/excessive accumulation phenomenon in low-temperature deposition manufacture

A low-temperature, automatic technology, applied in the field of incremental manufacturing, can solve problems such as excessive accumulation of forming, affecting product quality, blocked or bent nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

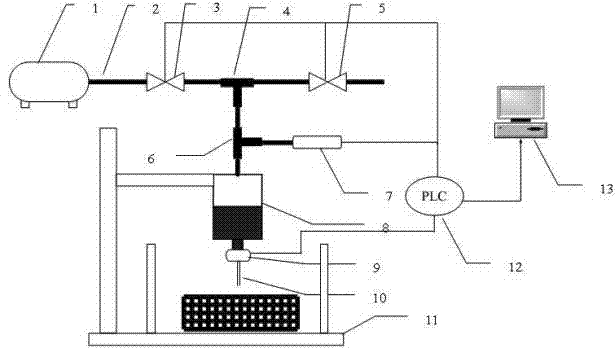

[0044] see figure 1 , a device for automatically eliminating under-lapping / over-piling phenomena in low-temperature deposition manufacturing, including a fast filling and deflation feeding device part and a control part, characterized in that: the fast charging and deflation feeding device part includes a voltage stabilizing Source device, air pressure regulating device, air pressure detection device and storage device. The pressure stabilizing source device is composed of an air compression part and a corresponding pressure regulating valve, and the air pressure regulating device is connected by an air charging valve and an exhaust valve; the air pressure detection device is connected to a barrel inlet of the material storage device The sensor is composed of; the storage device is composed of a material cylinder connected to a feeding solenoid valve and a nozzle in turn; the output port of the voltage stabilizing source device is connected to the input port of the air pressu...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0047] The fast filling and deflation type feeding device: the basic composition is as follows figure 1 As shown, it includes: pressure source 1, air pipe 2, inflation valve 3, three-way pipe 4, exhaust valve 5, sensor 7, barrel 8, feeding solenoid valve 9, nozzle 10 and system bracket 11, of which Provide the required stable air source for the voltage stabilizing device, ie the voltage stabilizing source 1, which consists of an air compression device, an air pump, a pressure reducing valve for air pressure regulation and an air storage tank. The air pressure regulating device is composed of a pressure regulating valve, that is, an inflation valve 3 and an exhaust valve 4, and a detection device, that is, a sensor. The nozzle 10 of the liquid outlet of the barrel is composed of a nozzle 10 at the outlet of the stabilized pressure source 1, which is connected to the inlet ...

Embodiment 3

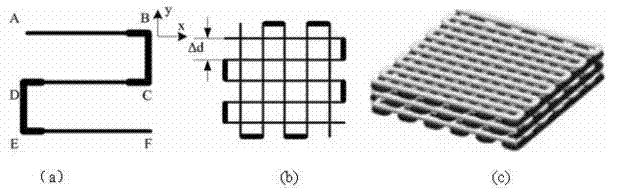

[0081] Embodiment 3: This embodiment takes the preparation of a biological bone scaffold with an internal X-Y cross grid at an angle of 90 degrees as an example.

[0082] In this example, a blend solution of 25% gelatin and 3% chitosan was used as the preparation material. The two component materials were weighed in proportion, and the mixing ratio was 5:1 to obtain a blended aqueous solution, which was loaded into a barrel. Due to the sensitivity of the gelatin material to temperature, in order to ensure good fluidity of the material, the barrel needs to be kept at 50°C. After connecting the discharge solenoid valve at the outlet of the barrel, install it on the system bracket. An air compressor with adjustable output is used as an air source, and the path track of the bracket is built as an X-Y cross grid, as shown in the attached figure 2 shown.

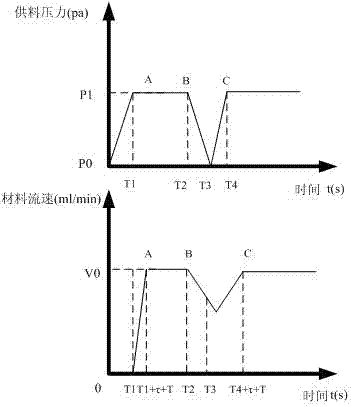

[0083] (1) Start the configuration interface of the upper computer, set the working parameters of the test device, call the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com