Lubricating oil anti-wear agent and preparation method thereof

A technology of anti-wear agent and lubricating oil, which is applied in the field of lubricating oil, can solve problems such as lubricating oil dispersion defects, machine wear, instability, etc., to improve anti-wear and extreme pressure performance, improve power output, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

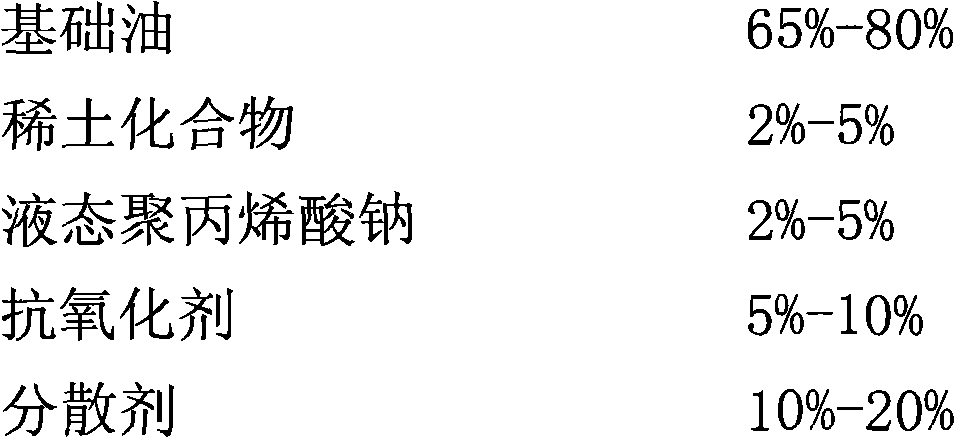

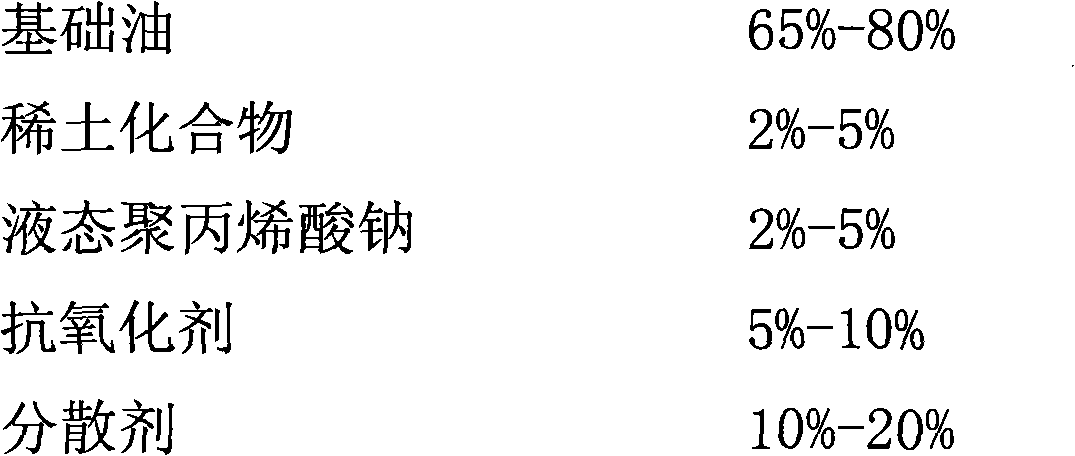

[0023] A lubricating oil antiwear agent comprising the following mass percentage components:

[0024]

[0025] The preparation method is as follows: 10% to 20% by weight of the dispersant is placed in the reactor 1, and 2% to 5% by weight of the rare earth compound is added thereto while stirring, and stirred in a water bath at 50 to 60°C until the rare earth compound is completely Dissolve; then place 65% to 80% by weight of base oil in reactor 2, add 2% to 5% by weight of sodium polyacrylate to it while stirring, and stir evenly; add the mixture obtained in the above reactor 1 to react In the vessel 2, finally add 2%-5% antioxidant by weight, and stir in a water bath at 50-60° C. for 30 minutes.

Embodiment 2

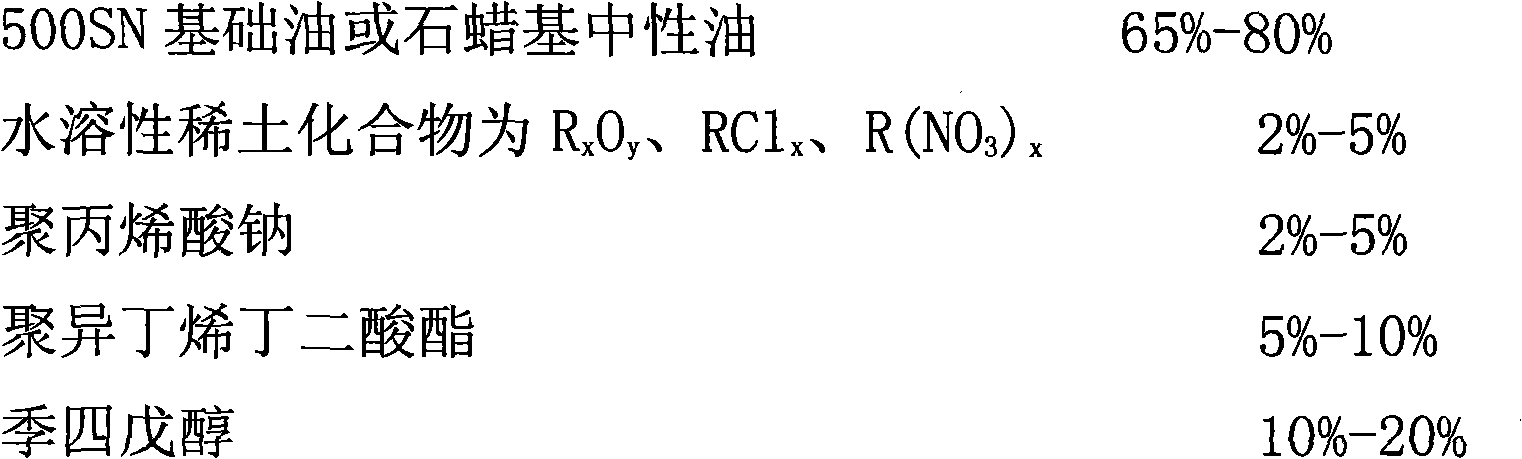

[0027] A kind of lubricating oil antiwear agent, its component and mass percentage are:

[0028]

[0029] Wherein, R is one of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium.

[0030] An antiwear agent for lubricating oil, the preparation method of which is as follows: 10% to 20% by weight of pentaerythyl alcohol is placed in a reactor 1, and 2% to 5% by weight of water-soluble rare earth is added thereto while stirring. Compound R x o y , RCl x , R(NO 3 ) x , wherein, R is one of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, stirred in a water bath at 50-60°C until water-soluble rare earth The compound is completely dissolved; then, 65% to 80% by weight of 500SN base oil or paraffin-based neutral oil is placed in the reactor 2, and 2% to 5% by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com