Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve anti-wear and anti-extreme pressure performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Total-synthesis hydraulic oil with super-long oil change period

InactiveCN105886071ASimple manufacturing schemeQuality improvementLubricant compositionAntioxidantViscosity index

The invention discloses total-synthesis hydraulic oil with a super-long oil change period. The hydraulic oil is characterized by consisting of base oil, an antioxidant, a detergent, a dispersing agent, a corrosion inhibitor, an antifoaming agent, a metal deactivator, a demulsifying agent, an anti-wear agent, an anti-extreme pressure agent, a viscosity index improver and a pour point reducer. In the invention, the production scheme is simple; and the product is cheaper than other products of the same type, has high quality and can effectively and comprehensively improve the performance requirements of lubricating oil. The anti-wear and anti-extreme pressure effects are enhanced to the greatest degree while the properties of lubricating oil including oxidation resistance, corrosion resistance, cleaning and dispersion, foam resistance, rust prevention and prevention of oil sludge generation are comprehensively improved. The life cycle of the hydraulic oil is greatly prolonged, and the noise of mechanical equipment and the energy consumption are reduced. The environmental protection requirements of existing products of the same type are completely exceeded.

Owner:TIANJIN CENTURY VALAVELINE PETROLEUM CO LTD

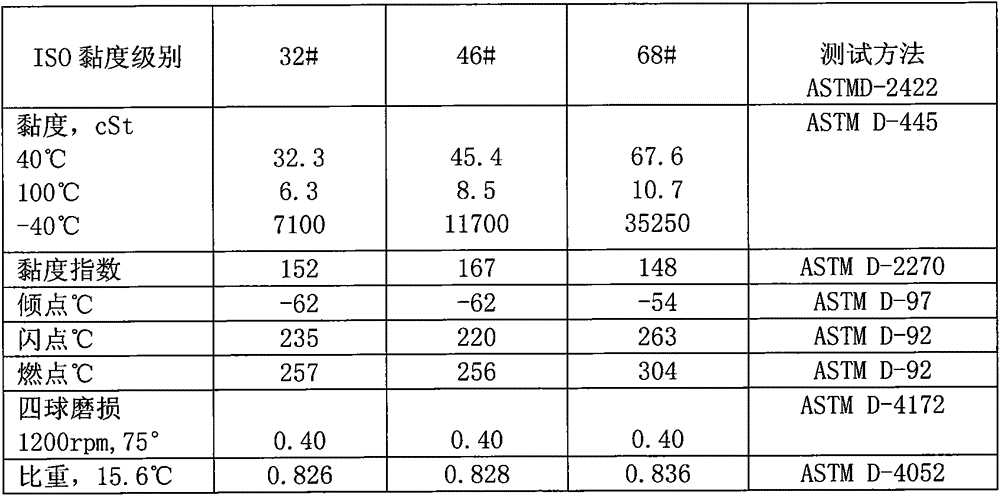

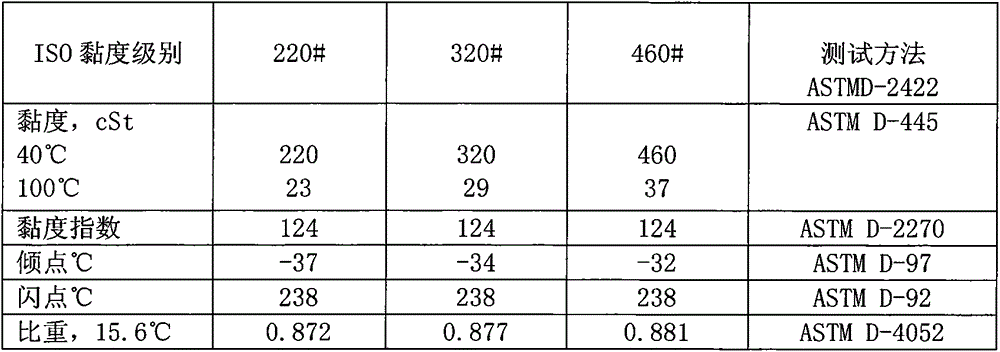

Fully synthetic super-extreme pressure-resistant industrial gear oil

InactiveCN105886072ASimple manufacturing schemeQuality improvementLubricant compositionChemistryPetroleum

The invention discloses fully synthetic super-extreme pressure-resistant industrial gear oil which is characterized by consisting of basic oil, an antioxidant, a detergent, a dispersing agent, a corrosion inhibitor, an anti-foaming agent, a metal deactivator, a demulsifying agent, an anti-wear agent, an extreme pressure-resistant agent, sulfide fatty acid ester, petroleum sodium sulfonate, zinc naphthenate, viscosity index improvers and pour point reducers. According to the invention, the manufacture scheme is simple, the price of the prepared product is lower than that of other similar products, the quality is high, and the various performance requirements of lubricating oil can be effectively and comprehensively improved. The oxidation resistance, corrosion resistance, detergent-dispersant property, foaming resistance, rust resistance and oil sludge resistance of the lubricating oil are comprehensively improved, and the wear-resistant and extreme pressure-resistant effects are improved to the greatest degree. The service cycle of heavy load industrial gear oil is prolonged, noise of mechanical equipment, and the energy consumption is reduced. The industrial gear oil completely goes beyond the environmental-friendly requirements of existing similar products.

Owner:TIANJIN CENTURY VALAVELINE PETROLEUM CO LTD

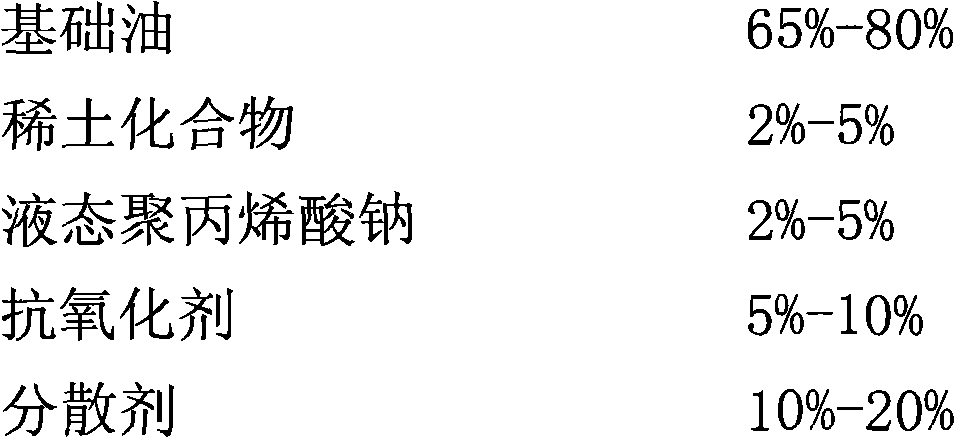

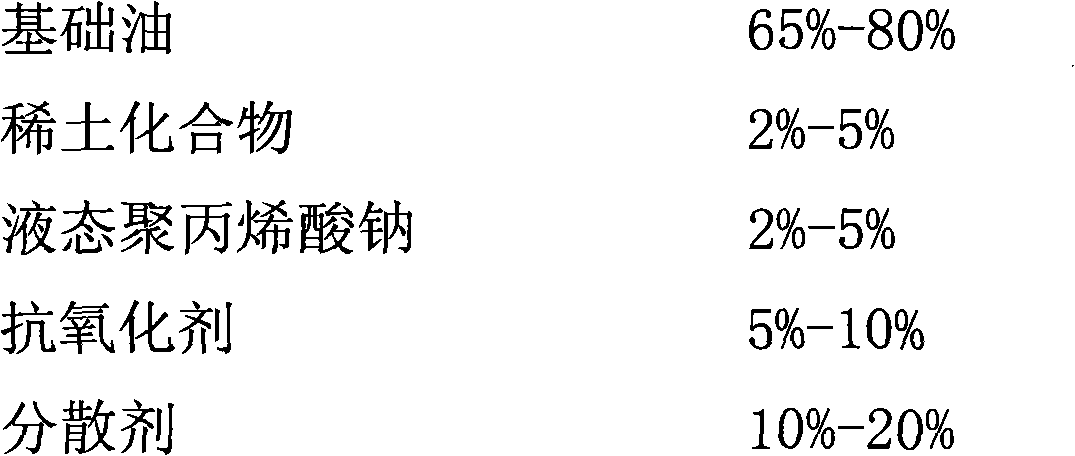

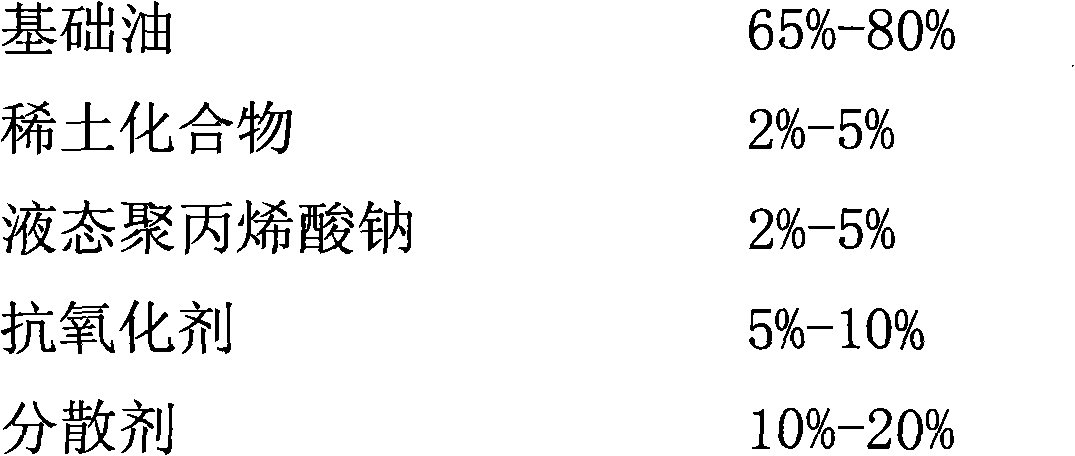

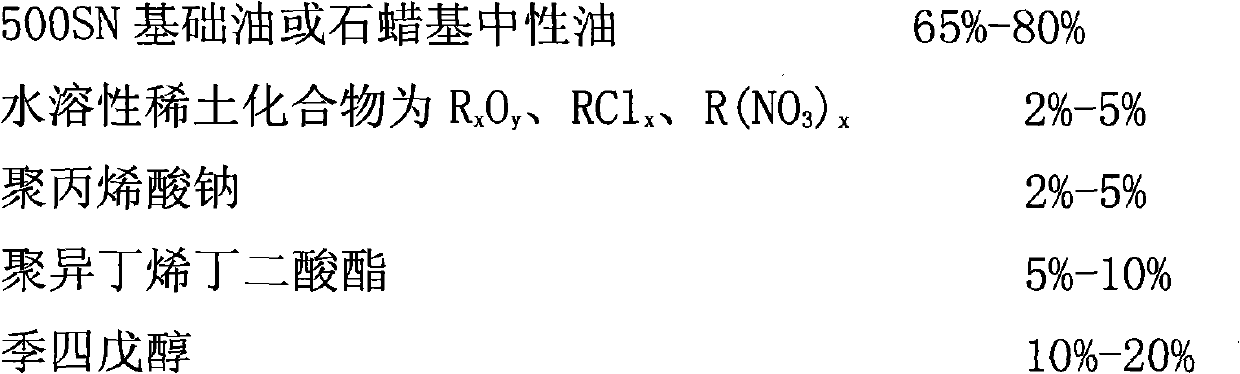

Lubricating oil anti-wear agent and preparation method thereof

InactiveCN103173268AImprove anti-wear and anti-extreme pressure performanceReduce wearAdditivesSulfurAntioxidant

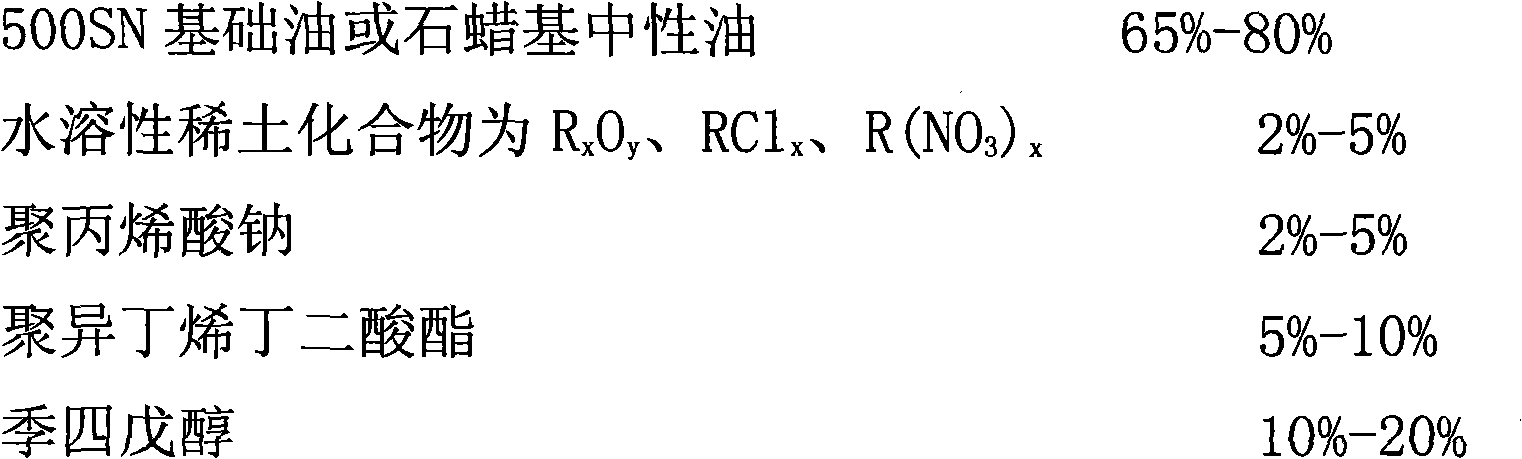

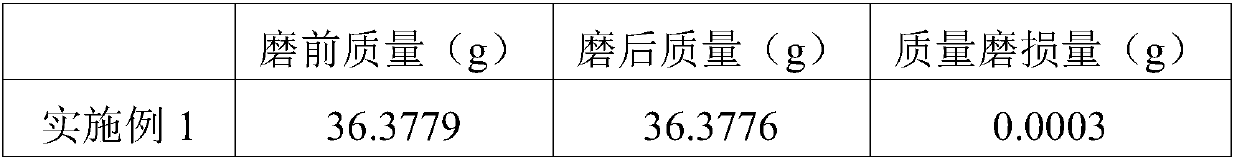

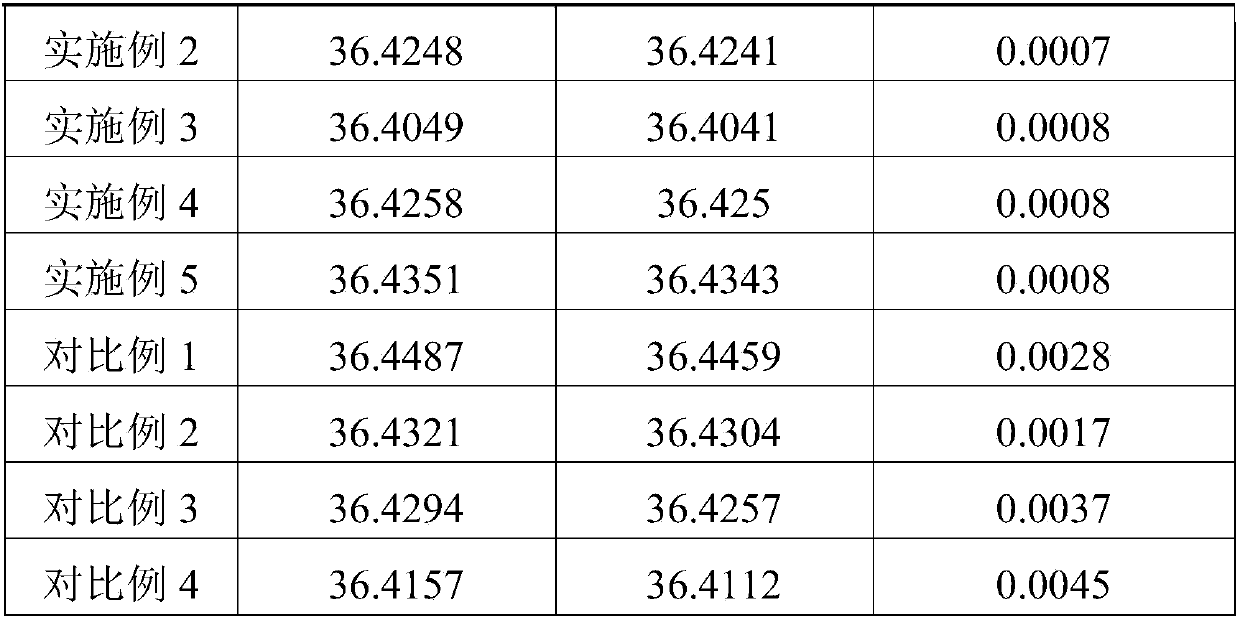

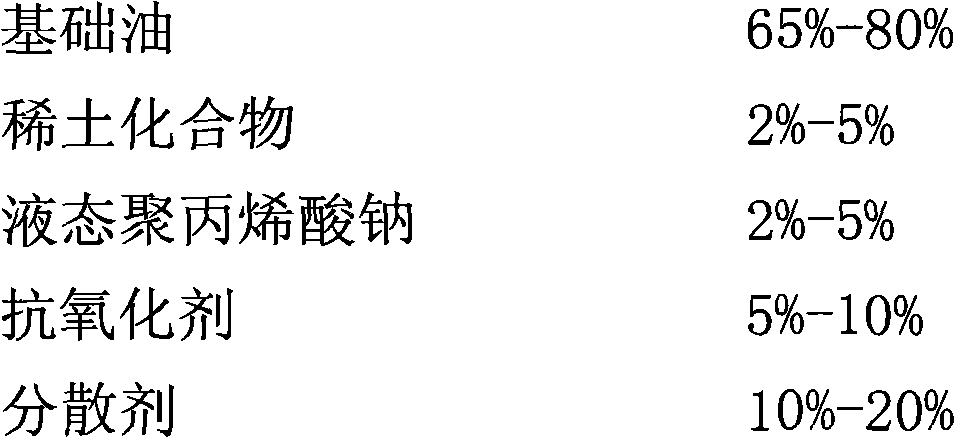

The invention discloses a lubricating oil anti-wear agent. The lubricating oil anti-wear agent comprises 65-80% by mass of base oil, 2-5% by mass of a rare earth compound, 2-5% by mass of liquid sodium polyacrylate, 5-10% by mass of an antioxidant, and 10-20% by mass of a dispersant. The lubricating oil anti-wear agent uses the unique chemical and physical performances of the rare earth compound, so the wear and extreme pressure resistances of oil are greatly improved; ionic bond exchange between sodium polyacrylate contained in the lubricating oil anti-wear agent and the surface of a metal facility is carried out, so a magnetic suspension effect is generated, and the part wearing is reduced; and no corrosive substances comprising sulfur or phosphorus are contained, so the lubricating oil anti-wear agent has no damages to parts, and does not cause environmental pollution.

Owner:北京房友录科技有限公司

Energy-saving emission-reducing nano wearproof lubricant special for heavy truck and method for producing the same

InactiveCN101481638AImprove viscosity-temperature characteristicsImprove cold exercise performanceLubricant compositionFuel oilBase oil

The invention relates to a energy-saving and emission-reduction type nano abrasion-resistant lubricating oil (meeting the requirements of the specifications of API / SAE CH-4 / SL 5W / 40 and 15W / 50), which is used for engines of heavy trucks, engineering plants, large agricultural machines, ships, trains, diesel generating sets, etc. The lubricating oil comprises the components based on the weight percentage: 150N 30-68%, 100N 0-10% and 150BS 10-35% of base oil, 0-5% of viscosity modifying agent VL 800, 10-14% of molecule abrasion-resistant complex additive Z3355, 2-5% of nano abrasion-resistant restoration agent H8001, 0.1-0.5% of pour point depressant PPT148 and 10-100PPM of defoaming agent D12500. The invention is used for engines of heavy trucks, engineering plants, large agricultural machines, ships, trains, diesel generating sets and the like, can save the fuel oil by 15-25%, reduces the pollutant discharge by 30-40%, prolongs the service life of the oil by three times reaching over 20000 kilometers, and has excellent viscosity-temperature characteristics. In the high temperature and severe cold regions, the invention can be used in the four seasons; as the base oil is purer and the protection of the additive is fuller, the nano abrasion-resistant lubricating oil is more beneficial to energy-saving and emission-reduction as well as prolonging the service of the engine.

Owner:姚明忠

Preparation method of composite nano anti-wearing additive used for lubricant oil

ActiveCN107880972AImprove anti-wear and anti-extreme pressure performanceEvenly dispersedAdditivesMolybdateFatty amine

The invention relates to the field of anti-wearing technology of lubricant oil and particularly relates to a preparation method of a composite nano anti-wearing additive used for lubricant oil. The preparation method includes the steps of: 1) preparing a hydrotalcite precursor; 2) performing a reaction to an aluminum source and fatty amine in water until precipitates are eliminated completely, andadding water-soluble silicate, molybdate and organo-titanate, uniformly mixing the component to form a first mixture system; 3) adding the hydrotalcite precursor and graphene and performing a reaction for 3-8 h at 60-120 DEG C, regulating the pH of the system to 3-5 to obtain a pre-product; 4) calcining the pre-product in inert gas to obtain the composite nano anti-wearing additive. In the invention, by adding the nano-particles to the hydrotalcite precursor and graphene, the anti-wearing nano-particles can enter the layered hydrotalcite-like compound layers and graphene layers and are uniformly dispersed in the system and blended with the lubricant oil well. The additive can effectively improve anti-wearing and anti-extreme pressure performances of the lubricant oil.

Owner:唐山诚佑科技有限公司

Efficient wear-resistant lubricating oil and preparation method thereof

InactiveCN107384551AImprove antioxidant capacityReduce wearLubricant compositionWear resistantAntioxidant

The invention discloses efficient wear-resistant lubricating oil. The efficient wear-resistant lubricating oil is prepared from components in parts by weight as follows: 40-60 parts of base oil, 30-40 parts of chlorinated paraffin, 20-30 parts of triphenyl phosphate, 10-30 parts of nano-graphite, 10-20 parts of nano-metal oxide, 5-15 parts of nano-aluminum, 3-8 parts of sepiolite, 5-10 parts of mica powder, 2-8 parts of sodium bentonite, 4-10 parts of calcium carbonate, 1-5 parts of an antioxidant, 0.5-3 parts of an antirust agent, 0.4-0.8 parts of an antifoaming agent and 0.2-0.8 parts of a pour point depressant. According to the efficient wear-resistant lubricating oil, defects of poor stability, weak oxidation resistance and poor wear-resistant effect in the prior art can be overcome, the lubricating oil with good stability, high anti-oxidative capacity and remarkable wear-resistant effect is provided, so that mechanical wear is reduced, and service life of machinery is prolonged.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Preparation method of lubricating oil anti-wear additive

ActiveCN107903986AEvenly dispersedImprove anti-wear and anti-extreme pressure performanceAdditivesWear resistantFatty amine

The invention relates to the technical field of lubricating oil wear resistance, and concretely relates to a preparation method of a lubricating oil anti-wear additive. The method comprises the following steps: 1, preparing a hydrotalcite precursor; (2) reacting an aluminum source with fatty amine in water until precipitate disappears completely, adding water-soluble silicate, and uniformly mixingthe obtained solution to obtain a mixed system 1; (3) adding the hydrotalcite precursor and expanded graphite to the mixed system 1, carrying out a reaction at 60-120 DEG C for 3-8 h, and adding an acidic substance to adjust the pH value of the system to 3-5 in order to obtain a pre-product; and (4) calcining the pre-product in an inert gas to obtain the lubricating oil anti-wear additive. Nano-particles are added to the hydrotalcite precursor and the expanded graphite to make wear-resistant nano-particles enter layered hydrotalcite-like interlayer and expanded graphite interlayer, so the wear-resistant particles are evenly dispersed in the system and are well fused into lubricating oil, thereby the anti-wear and anti-extreme pressure performances of the lubricating oil are effectively improved.

Owner:洛斯石油(浙江)有限公司

Anti-wearing extreme-pressure-resistant lubricating oil

InactiveCN106467838AHigh performance requirementsImprove the performance requirements and improve the oxidation resistance of lubricating oil in an all-round wayAdditivesDispersityRhenium

The invention discloses anti-wearing extreme-pressure-resistant lubricating oil which consists of base oil, an antioxidant, a detergent, a dispersing agent, an extreme-pressure anti-wearing agent, a viscosity index improver, a nano-grade rhenium-molybdenum alloy powder material, polyacrylate, a thyoxyl phenol, benzotriazole and vulcanized dipolybutylene, wherein the antioxidant is shielding bisphenol; the detergent calcium-based phenolate; the dispersing agent is sodium polyacrylate; the extreme-pressure anti-wearing agent is chlorinated paraffin; the viscosity index improver is a styrene diene copolymer. The anti-wearing extreme-pressure-resistant lubricating oil has the advantages of being scientific in preparation scheme and simple in preparation method, the price of a prepared product is lower than that of a similar product, various property requirements of the anti-wearing extreme-pressure-resistant lubricating oil can be effectively and comprehensively improved, the oxidation resistance, the corrosion resistance, the detergence and dispersity, the anti-rusting property, the bubble resistance and the greasy sludge prevention property of the anti-wearing extreme-pressure-resistant lubricating oil can be comprehensively improved, the effects of wearing resistance and extreme pressure resistance can be improved to the maximum extent, meanwhile a very good remediation function on a wearing surface of an engine can be achieved, the lubricating oil change period can be prolonged, the noise can be reduced, and the exhaust gas emission can be reduced.

Owner:华信凯伟科技(天津)有限公司

Gasoline engine oil based on extreme pressure anti-wear agent and preparation method of gasoline engine oil

InactiveCN114317079AExtend maintenance life cycleMeet high performance requirementsLubricant compositionPhosphoric Acid EstersAntioxidant

The invention discloses gasoline engine oil based on an anti-wear reagent at extreme pressure and a preparation method of the gasoline engine oil, and the gasoline engine oil based on the anti-wear reagent at extreme pressure comprises the following components in parts by weight: 70-98 parts of base oil, 0.2-8 parts of the anti-wear reagent at extreme pressure, 0.1-5 parts of a tackifier, 0.05-5 parts of a metal deactivator, 0.05-5 parts of a pour point depressant, 0.5-2 parts of an antioxidant and 0.01-0.05 part of a demulsifier, the anti-wear reagent at extreme pressure is selected from one or more of tricresyl phosphate, sulfurized olefin, phenyl sulfide, sulfurized fatty acid ester, alkyl thiophosphate and a sulfur-nitrogen type anti-wear reagent at extreme pressure. According to the technical scheme, the extreme pressure anti-wear agent, the tackifier, the metal deactivator, the pour point depressant, the antioxidant and the demulsifier are mixed and matched with one another, the manufacturing process is simple, excessive processing equipment does not need to be input, the comprehensive performance requirement of the lubricating oil can be effectively and comprehensively improved, the maintenance and use period of gasoline engine oil is effectively prolonged, and the production cost is reduced. The anti-wear and anti-extreme pressure effects of the product are improved to the maximum extent.

Owner:无锡奇比特润滑油有限公司

Anti-wear lubricating oil composite agent

InactiveCN106467827AFully functionalImprove antioxidant capacityLubricant compositionPrice ratioCleansing Agents

The invention relates to an anti-wear lubricating oil composite agent, which is characterized by comprising base oil, an antioxidant, a cleaning agent, a dispersant, an extreme pressure anti-wear agent, a rust corrosion inhibitor, a pour point depressant, a metal deactivator, nanometer zinc, and tungsten disulfide, wherein the antioxidant is glycerol monooleate, the cleaning agent is a sulfated polyisobutylene salt, the dispersant is a styrene ester derivative, the extreme pressure anti-wear agent is vulcanized isobutylene, the rust corrosion inhibitor is synthetic sodium sulfonate, the pour point depressant is alkyl naphthalene, and the metal deactivator is benzotriazole. According to the present invention, the manufacturing method is simple; and the prepared product has characteristics of low price, high efficiency, high performance price ratio, complete providing of the comprehensive effect of the lubricating oil, strong repair on the aging wear of the mechanical equipment, improvement of the oxidation resistance and the corrosion resistance of the lubricating oil, cleaning effect, dispersing effect, simultaneous improvement of the wear resistance and the extreme pressure resistance, noise reducing, tail gas emission reducing, oil change period prolonging, fuel oil saving, and complete improvement of the comprehensive effect of the lubricating oil.

Owner:华信凯伟科技(天津)有限公司

Lubricating oil for engine

InactiveCN106467835AMeet high performance requirementsImprove antioxidant capacityLubricant compositionRheniumAlloy

The invention provides a lubricating oil for an engine. The lubricating oil is composed of base oil, an anti-oxidant, a detergent additive, a dispersing agent, an anti-wear reagent at extreme pressure, a viscosity index improver, nanometer rhenium-molybdenum alloy powder, polyacrylate, ethoxyphenol, benzotriazole and sulfurized dipolybutene, wherein the anti-oxidant is aromatic amine; the detergent additive is salicylate; the dispersing agent is succimide; the anti-wear reagent at extreme pressure is diaryl disulfide; and the viscosity index improver is an alkene copolymer. The lubricating oil provided by the invention has the advantages that a preparation scheme for the lubricating oil is scientific; a manufacturing method for the lubricating oil is simple; the prepared lubricating oil is lower in price compared with products of a same kind; each performance of the lubricating oil is comprehensively improved; the anti-wear and anti-extreme pressure performance of the lubricating oil are maximally enhanced while corrosion resistance, cleaning performance, dispersing performance, rust resistance, foaming resistance and resistance to generation of greasy filth are improved; and the lubricating oil exerts strong repair effect on the magic surface of the engine, prolongs an oil change period, reduces noise and decreases discharge of tail gas.

Owner:华信凯伟科技(天津)有限公司

Antiwear complexing agent for engine oil

The invention provides an antiwear complexing agent for engine oil. The antiwear complexing agent is characterized by being composed of base oil, an antioxidant, a detergent, a dispersant, an extreme pressure antiwear agent, a rust inhibitor, a pour point depressant, a metal deactivator, nanometer zinc and tungsten disulfide, wherein the antioxidant is dihydro benzothiophene; the detergent is phenate; the dispersant is polyisobutylene glyceryl maleate; the extreme pressure antiwear agent is lead naphthenate; the rust inhibitor is an alkyl succinic acid derivative; the pour point depressant is alkyl naphthalene; and the metal deactivator is benzotriazole. According to the invention, the manufacturing method is simple; and the prepared product has low price, high efficiency and high cost performance, gives full play to comprehensive effects of lubricating oil, has strong repair effect on aging and wearing of mechanical equipment, can improve oxidation-resistant, corrosion-resistant, cleaning and dispersing effects of the lubricating oil and improves antiwear and anti-extreme-pressure effects at the same time, reduces noise and exhaust emission, prolongs the oil changing period, saves fuel oil, and completely enhances comprehensive effects of the lubricating oil.

Owner:华信凯伟科技(天津)有限公司

Fully effective lubricating oil used for engine

InactiveCN105602663AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumMechanical equipment

The invention relates to fully effective lubricating oil used for engine. The fully effective lubricating oil is composed of base oil, base liquid, lecithin, a tungsten-rhenium alloy, an anti-oxidant, clearing agent, a dispersant, a corrosion inhibitor, an anti-foaming agent, a metal passivator, a demulsifying agent, an anti-wear agent, an extreme pressure additive, and a viscosity index improver. A production scheme of the lubricating oil is simple, the price of the lubricating oil is lower than that of the other same kind products, and the lubricating oil has high quality and can effectively and comprehensively enhance the performance requirements of the lubricating oil. Anti-oxidation, corrosion resistance, detergency and dispersibility, foaming resistance, rust prevention, and oil sludge generation resistance of the lubricating oil can be comprehensively increased, and anti-wear and anti-extreme pressure performances can be increased at maximum limit. The lubricating oil can prolong the usage period, reduces noise of mechanical equipment, reduces energy consumption, and reduces tail gas discharge. The lubricating oil completely exceeds the environmental protection requirement of the current same kind products.

Owner:TIANJIN ZECHANG TECH

Anti-wearing lubricating oil

InactiveCN106467837AMeet high performance requirementsImprove antioxidant capacityLubricant compositionRheniumDispersity

The invention discloses anti-wearing lubricating oil which consists of base oil, an antioxidant, a detergent, a dispersing agent, an extreme-pressure anti-wearing agent, a viscosity index improver, a nano-grade rhenium-molybdenum alloy powder material, polyacrylate, an ethyoxyl phenol, benzotriazole and vulcanized dipolybutylene, wherein the antioxidant is alkyl diphenylamine; the detergent is sulfonate; the dispersing agent is a mannich ashless dispersing agent; the extreme-pressure anti-wearing agent is dialkyl phosphorodithioate; the viscosity index improver is an olefin copolymer. The anti-wearing lubricating oil has the advantages of being scientific in preparation scheme and simple in preparation method, the price of a prepared product is lower than that of a similar product, various property requirements of the anti-wearing lubricating oil can be effectively and comprehensively improved, the oxidation resistance, the corrosion resistance, the detergence and dispersity, the anti-rusting property, the bubble resistance and the greasy sludge prevention property of the anti-wearing lubricating oil can be comprehensively improved, the effects of wearing resistance and extreme pressure resistance can be improved to the maximum extent, meanwhile a very good remediation function on a wearing surface of an engine can be achieved, the lubricating oil change period can be prolonged, the noise can be reduced, and the exhaust gas emission can be reduced.

Owner:华信凯伟科技(天津)有限公司

Additive for antiwear lubricating oil

InactiveCN106467826AFully functionalImprove antioxidant capacityLubricant compositionAntioxidantDepressant

The invention provides an additive for antiwear lubricating oil. The additive is characterized by being composed of base oil, an antioxidant, a detergent, a dispersant, an extreme pressure antiwear agent, a rust inhibitor, a pour point depressant, a metal deactivator, nanometer zinc and tungsten disulfide, wherein the antioxidant is phenothiazine; the detergent is sulfurized calcium alkyl phenate; the dispersant is a styrene ester derivative; the extreme pressure antiwear agent is ammonium dithiophosphate; the rust inhibitor is barium petroleum sulfonate; the pour point depressant is poly-alpha-olefin; and the metal deactivator is a toluoyl triazole derivative. According to the invention, the manufacturing method is simple; and the prepared product has low price, high efficiency and high cost performance, gives full play to comprehensive effects of lubricating oil, has strong repair effect on aging and wearing of mechanical equipment, can improve oxidation-resistant, corrosion-resistant, cleaning and dispersing effects of the lubricating oil and improves antiwear and anti-extreme-pressure effects at the same time, reduces noise and exhaust emission, prolongs the oil changing period, saves fuel oil, and completely enhances comprehensive effects of the lubricating oil.

Owner:华信凯伟科技(天津)有限公司

Full-function lubricating oil applied to engine

InactiveCN105886037AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumAntioxidant

The invention relates to full-function lubricating oil applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Full-function lubricating oil capable of being applied to engine

InactiveCN105886062AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumAntioxidant

The invention relates to full-function lubricating oil capable of being applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Lubricating oil used in engine

InactiveCN106467833AHigh performance requirementsImprove the performance requirements and improve the oxidation resistance of lubricating oil in an all-round wayLubricant compositionRheniumDispersity

The invention discloses lubricating oil used in an engine. The lubricating oil consists of base oil, an antioxidant, a detergent, a dispersing agent, an extreme-pressure anti-wearing agent, a viscosity index improver, a nano-grade rhenium-molybdenum alloy powder material, polyacrylate, an ethyoxyl phenol, benzotriazole and vulcanized dipolybutylene, wherein the antioxidant is sterically hindered phenol; the detergent is barium hydroxide; the dispersing agent is succinate; the extreme-pressure anti-wearing agent is an alkyl phosphorus-containing acid ester and salt; the viscosity index improver is poly(alkyl methacrylate). The lubricating oil has the advantages of being scientific in preparation scheme and simple in preparation method, the price of a prepared product is lower than that of a similar product, various property requirements of the lubricating oil can be effectively and comprehensively improved, the oxidation resistance, the corrosion resistance, the detergence and dispersity, the anti-rusting property, the bubble resistance and the greasy sludge prevention property of the lubricating oil can be comprehensively improved, the effects of wearing resistance and extreme pressure resistance can be improved to the maximum extent, meanwhile a very good remediation function on a wearing surface of the engine can be achieved, the lubricating oil change period can be prolonged, the noise can be reduced, and the exhaust gas emission can be reduced.

Owner:华信凯伟科技(天津)有限公司

Fully-effective lubricating oil applied to engines

InactiveCN105886033AMeet high performance requirementsImprove antioxidant capacityLubricant compositionRheniumAntioxidant

The invention provides fully-effective lubricating oil applied to engines. The lubricating oil is characterized by consisting of base oil, base liquid, liquid vitamin E, a rhenium-tungsten alloy, an antioxidant, a cleaning agent, a dispersant, a corrosion inhibitor, an anti-forming agent, a metal passivator, a demulsifying agent, an antiwear agent, an anti-extreme pressure agent, and a viscosity index improver. The lubricating oil provided by the invention has a simple manufacturing scheme, the price of a prepared product is lower than prices of other products of the same kind, the lubricating oil has high quality, and each performance requirement of the lubricating oil is comprehensively and effectively improved. The effects of resisting abrasion and extreme pressure of the lubricating oil can be improved to the maximum extent while the performances of the lubricating oil such as oxidation resistance, corrosion resistance, lustration decentralization, anti-foaming property, antirust property, and greasy filth generation prevention are comprehensively improved. The lubricating oil has the advantages of a prolonged service cycle, reduced noise of mechanical equipment, reduced energy consumption, and reduced tail gas discharge, and completely exceeds environmental protection requirements of present products of the same kind.

Owner:TIANJIN ZECHANG TECH

Full-function lubricating oil capable of being applied in engine

InactiveCN105886052ASimple manufacturing schemeQuality improvementLubricant compositionCorrosionViscosity index

The invention provides full-function lubricating oil capable of being applied in an engine. The lubricating oil is characterized by being composed of base oil, base fluid, liquid vitamin E, a rhenium-tungsten alloy, an anti-oxidant, a detergent, a dispersant, a rusting inhibitor, an anti-foaming agent, a metal deactivator, a demulsifying agent, an antiwear agent, an extreme pressure resisting agent and a viscosity index improver. The lubricating oil provided by the invention has the following advantages: a manufacturing scheme of the invention is simple; the prepared lubricating oil has a price lower than the price of products of a same kind, has high quality, and can effectively and comprehensively improve the requirements for performances of the lubricating oil; oxidation resistance, corrosion resistance, detergency, dispersibility, foaming resistance, rusting resistance and oil sludge generation resistance of the lubricating oil are comprehensively improved; meanwhile, the functions of wear resistance and extreme pressure resistance of the lubricating oil are maximumly improved; the life cycle of the lubricating oil is prolonged; the noise of mechanical equipment is reduced; energy consumption is lowered; exhaust emission is decreased; and the requirement for environmental protection of the lubricating oil is completely beyond the requirement for environmental protection of products of a same kind.

Owner:TIANJIN ZECHANG TECH

Full-function lubricating oil capable of being applied to engine

InactiveCN105886059ASimple manufacturing schemeQuality improvementLubricant compositionTungstenCorrosion

The invention relates to full-function lubricating oil capable of being applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Lubricating oil anti-wear agent and preparation method thereof

InactiveCN103173268BImprove anti-wear and anti-extreme pressure performanceReduce wearAdditivesAntioxidantSulfur

The invention discloses a lubricating oil anti-wear agent. The lubricating oil anti-wear agent comprises 65-80% by mass of base oil, 2-5% by mass of a rare earth compound, 2-5% by mass of liquid sodium polyacrylate, 5-10% by mass of an antioxidant, and 10-20% by mass of a dispersant. The lubricating oil anti-wear agent uses the unique chemical and physical performances of the rare earth compound, so the wear and extreme pressure resistances of oil are greatly improved; ionic bond exchange between sodium polyacrylate contained in the lubricating oil anti-wear agent and the surface of a metal facility is carried out, so a magnetic suspension effect is generated, and the part wearing is reduced; and no corrosive substances comprising sulfur or phosphorus are contained, so the lubricating oil anti-wear agent has no damages to parts, and does not cause environmental pollution.

Owner:北京房友录科技有限公司

Antiwear complexing agent for engine lubricating oil

The invention provides an antiwear complexing agent for engine lubricating oil. The antiwear complexing agent is characterized by being composed of base oil, an antioxidant, a detergent, a dispersant, an extreme pressure antiwear agent, a rust inhibitor, a pour point depressant, a metal deactivator, nanometer zinc and tungsten disulfide, wherein the antioxidant is sulfur butyl octyl zinc salt; the detergent is naphthenate; the dispersant is monobutyl imide; the extreme pressure antiwear agent is molybdenum carboxylate; the rust inhibitor is dodecencylsuccinic acid; the pour point depressant is polymethacrylate; and the metal deactivator is benzotriazole. According to the invention, the manufacturing method is simple; and the prepared product has low price, high efficiency and high cost performance, gives full play to comprehensive effects of lubricating oil, has strong repair effect on aging and wearing of mechanical equipment, can improve oxidation-resistant, corrosion-resistant, cleaning and dispersing effects of the lubricating oil and improves antiwear and anti-extreme-pressure effects at the same time, reduces noise and exhaust emission, prolongs the oil changing period, saves fuel oil, and completely enhances comprehensive effects of the lubricating oil.

Owner:华信凯伟科技(天津)有限公司

Anti-wear lubricating oil for engine

InactiveCN106467834AHigh performance requirementsImprove the performance requirements and improve the oxidation resistance of lubricating oil in an all-round wayLubricant compositionRheniumPhosphate

The invention provides an anti-wear lubricating oil for an engine. The anti-wear lubricating oil is composed of base oil, an anti-oxidant, a detergent additive, a dispersing agent, an anti-wear reagent at extreme pressure, a viscosity index improver, nanometer rhenium-molybdenum alloy powder, polyacrylate, ethoxyphenol, benzotriazole and sulfurized dipolybutene, wherein the anti-oxidant is aryl phosphite; the detergent additive is sulfite; the dispersing agent is succimide; the anti-wear reagent at extreme pressure is molybdenum phosphate; and the viscosity index improver is a styrene-diene copolymer. The anti-wear lubricating oil provided by the invention has the advantages that a preparation scheme for the lubricating oil is scientific; a manufacturing method for the lubricating oil is simple; the prepared lubricating oil is lower in price compared with products of a same kind; each performance of the lubricating oil is comprehensively improved; the anti-wear and anti-extreme pressure performance of the lubricating oil are maximally enhanced while corrosion resistance, cleaning performance, dispersing performance, rust resistance, foaming resistance and resistance to generation of greasy filth are improved; and the lubricating oil exerts strong repair effect on the magic surface of the engine, prolongs an oil change period, reduces noise and decreases discharge of tail gas.

Owner:华信凯伟科技(天津)有限公司

Fully-effective lubricating oil applied to engines

InactiveCN105886034ASimple manufacturing schemeQuality improvementAdditivesAntioxidantViscosity index

The invention provides fully-effective lubricating oil applied to engines. The lubricating oil is characterized by consisting of base oil, base liquid, liquid vitamin E, a rhenium-tungsten alloy, an antioxidant, a cleaning agent, a dispersant, a corrosion inhibitor, an anti-forming agent, a metal passivator, a demulsifying agent, an antiwear agent, an anti-extreme pressure agent, and a viscosity index improver. The lubricating oil provided by the invention has a simple manufacturing scheme, the price of a prepared product is lower than prices of other products of the same kind, the lubricating oil has high quality, and each performance requirement of the lubricating oil is comprehensively and effectively improved. The effects of resisting abrasion and extreme pressure of the lubricating oil can be improved to the maximum extent while the performances of the lubricating oil such as oxidation resistance, corrosion resistance, lustration decentralization, anti-foaming property, antirust property, and greasy filth generation prevention are comprehensively improved. The lubricating oil has the advantages of a prolonged service cycle, reduced noise of mechanical equipment, reduced energy consumption, and reduced tail gas discharge, and completely exceeds environmental protection requirements of present products of the same kind.

Owner:TIANJIN ZECHANG TECH

Full-function lubricating oil capable of being applied in engine

InactiveCN105886053AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumMechanical equipment

The invention provides full-function lubricating oil capable of being applied in an engine. The lubricating oil is characterized by being composed of base oil, base fluid, liquid vitamin E, a rhenium-tungsten alloy, an anti-oxidant, a detergent, a dispersant, a rusting inhibitor, an anti-foaming agent, a metal deactivator, a demulsifying agent, an antiwear agent, an extreme pressure resisting agent and a viscosity index improver. The lubricating oil provided by the invention has the following advantages: a manufacturing scheme of the invention is simple; the prepared lubricating oil has a price lower than the price of products of a same kind, has high quality, and can effectively and comprehensively improve the requirements for performances of the lubricating oil; oxidation resistance, corrosion resistance, detergency, dispersibility, foaming resistance, rusting resistance and oil sludge generation resistance of the lubricating oil are comprehensively improved; meanwhile, the functions of wear resistance and extreme pressure resistance of the lubricating oil are maximumly improved; the life cycle of the lubricating oil is prolonged; the noise of mechanical equipment is reduced; energy consumption is lowered; exhaust emission is decreased; and the requirement for environmental protection of the lubricating oil is completely beyond the requirement for environmental protection of products of a same kind.

Owner:TIANJIN ZECHANG TECH

Anti-wearing extreme-pressure-resistant engine lubricating oil

InactiveCN106467839AMeet high performance requirementsImprove antioxidant capacityLubricant compositionDispersityRhenium

The invention discloses anti-wearing extreme-pressure-resistant engine lubricating oil which consists of base oil, an antioxidant, a detergent, a dispersing agent, an extreme-pressure anti-wearing agent, a viscosity index improver, a nano-grade rhenium-molybdenum alloy powder material, polyacrylate, an ethyoxyl phenol, benzotriazole and vulcanized dipolybutylene, wherein the antioxidant is an thioether liquid of shielding phenol; the detergent is sulfurized alkyl phenate; the dispersing agent is a styrene ester derivative; the extreme-pressure anti-wearing agent is a composite ester of a high molecular weight; the viscosity index improver is a styrene diene copolymer. The anti-wearing extreme-pressure-resistant engine lubricating oil has the advantages of being scientific in preparation scheme and simple in preparation method, the price of a prepared product is lower than that of a similar product, various property requirements of the anti-wearing extreme-pressure-resistant engine lubricating oil can be effectively and comprehensively improved, the oxidation resistance, the corrosion resistance, the detergence and dispersity, the anti-rusting property, the bubble resistance and the greasy sludge prevention property of the anti-wearing extreme-pressure-resistant engine lubricating oil can be comprehensively improved, the effects of wearing resistance and extreme pressure resistance can be improved to the maximum extent, meanwhile a very good remediation function on a wearing surface of an engine can be achieved, the lubricating oil change period can be prolonged, the noise can be reduced, and the exhaust gas emission can be reduced.

Owner:华信凯伟科技(天津)有限公司

Full-function lubricating oil capable of being applied to engine

InactiveCN105886061AMeet high performance requirementsImprove antioxidant capacityLubricant compositionAntioxidantAlloy

The invention relates to full-function lubricating oil capable of being applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Full-efficient lubricating oil applied to engines

InactiveCN105602669AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumMechanical equipment

The invention provides full-efficient lubricating oil applied to engines. The lubricating oil is characterized in that the lubricating oil comprises the following components: base oil, base liquid, liquid vitamin E, rhenium-tungsten alloy, an anti-oxidant, a cleaning agent, a dispersant, a corrosion inhibitor, an anti-forming agent, a metal passivator, a demulsifying agent, an antiwear agent, an anti-extreme pressure agent, and a viscosity index improver. The lubricating oil has a simple manufacture scheme, the price of the prepared product is lower than prices of other products of the same kind, the lubricating oil has high quality, and each performance of the lubricating oil is comprehensively and effectively improved. The full-efficient lubricating oil has the advantages of antioxidation, corrosion resistance, detergency and dispersibility, foaming resistance, rust protection, greasy generation resistance, and improvements of antiwear efficacy and antiwear efficacy at extreme pressure to the largest extent. The lubricating oil has the advantages of prolonged service cycle, reduced noise of mechanical equipment, reduced energy consumption, and reduced tail gas discharge. The lubricating oil completely exceeds environmental protection requirements of products of the same kind.

Owner:TIANJIN ZECHANG TECH

Full-function lubricating oil capable of being applied to engine

InactiveCN105886060AHigh performance requirementsImprove antioxidant capacityLubricant compositionRheniumAntioxidant

The invention relates to full-function lubricating oil capable of being applied to an engine. The full-function lubricating oil is characterized by being prepared from base oil, base liquid, liquid vitamin E, tungsten-rhenium alloy, an antioxidant, a detergent, a dispersant, a rust inhibitor, an antifoamer, a metal deactivator, a demulsifier, an anti-wear agent, an extreme pressure resisting agent and a viscosity index improver. According to the full-function lubricating oil, the preparation scheme is simple, the price of the prepared product is lower than that of other like products, the quality is high, and various performance requirements of the lubricating oil can be effectively and comprehensively improved. The antiwear and extreme pressure resisting effects are improved to the maximum while the oxidation resistance, corrosion resistance, detergency, dispersion, foaming resistance, rust prevention and oil sludge generation resistance of the lubricating oil are comprehensively improved. The use cycle of the lubricating oil is prolonged, the noise of mechanical equipment is lowered, the energy consumption is lowered, and exhaust emissions are reduced. The lubricating oil completely exceeds the environment-friendly requirements of the like products.

Owner:TIANJIN ZECHANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com