A method for optimizing the oxygen content in the bi-2223 phase of superconducting tape and the resulting superconducting wire

A bi-2223, superconducting tape technology, applied in superconducting/high-conducting conductors, usage of superconducting elements, superconducting devices, etc., to achieve the effects of increasing content, increasing critical current, and improving magnetic field performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

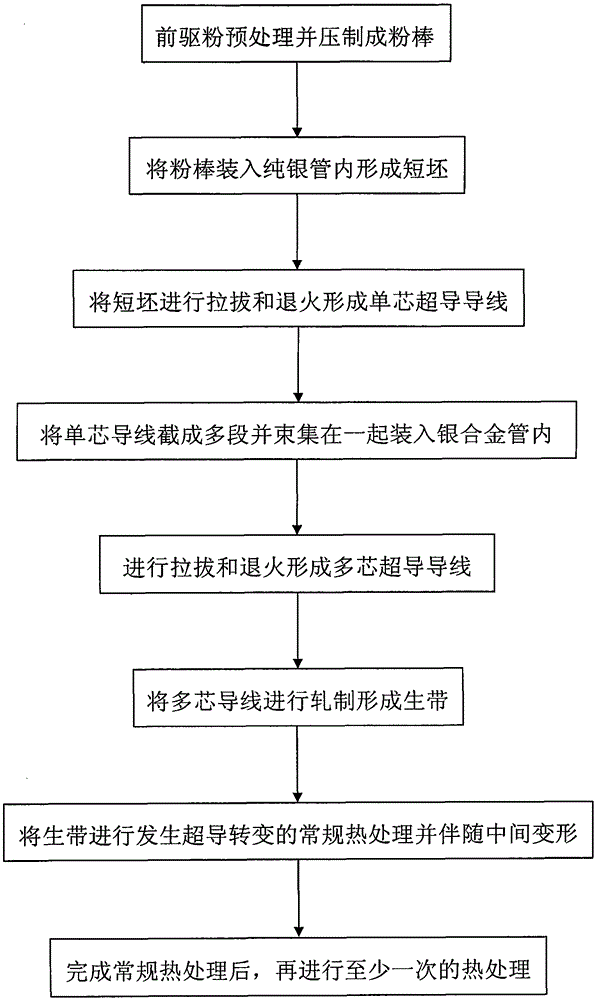

Method used

Image

Examples

Embodiment 1

[0043] Heat treatment process: one heat treatment (HT1), the oxygen partial pressure is 0.5%, the temperature is 400°C, and the holding time is 500h.

[0044] After the above heat treatment process, the critical transition temperature (Tc) of the superconducting tape is 110K, and the critical current (Ic) is 127A.

Embodiment 2

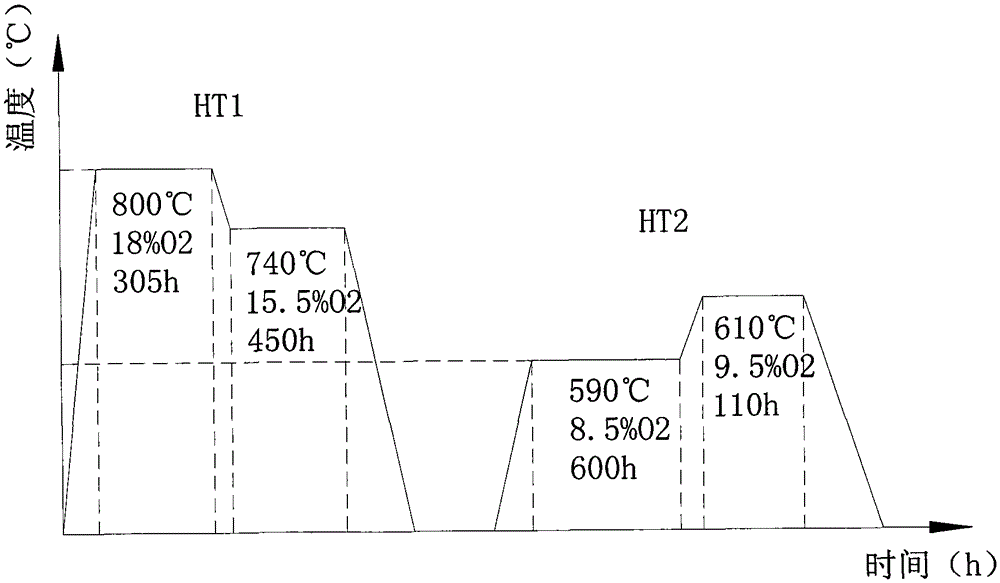

[0046] Heat treatment process: primary heat treatment (HT1), the oxygen partial pressure is 10%, the temperature is 455°C, and the holding time is 10h; the temperature is raised to 620°C, and the holding time is continued for 120h, and the oxygen partial pressure remains unchanged.

[0047] After the above heat treatment process, the critical transition temperature (Tc) of the superconducting tape is 113K, and the critical current (Ic) is 120A.

Embodiment 3

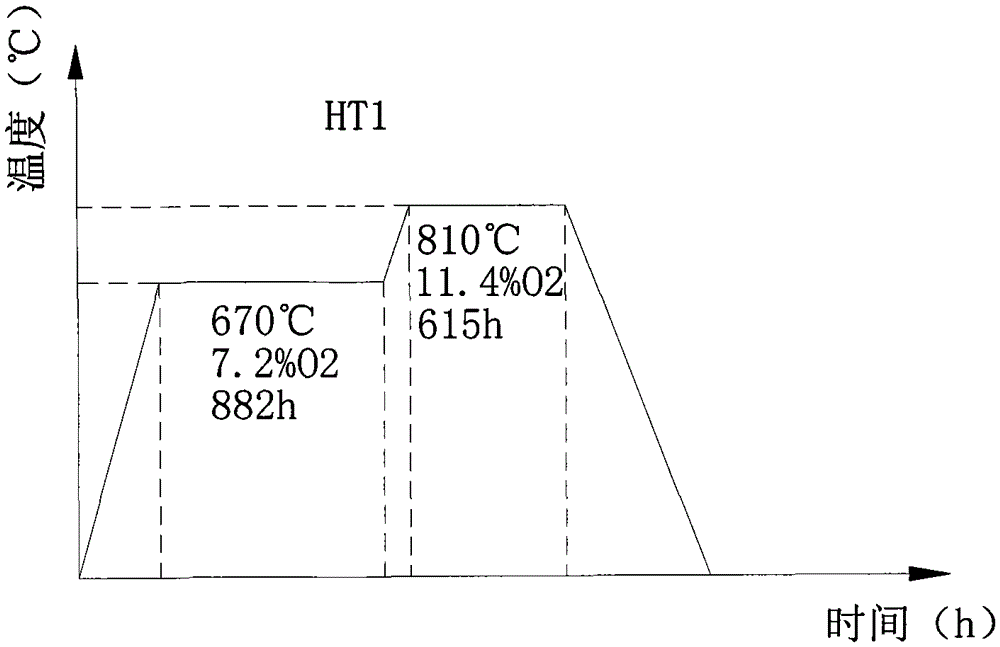

[0049] Heat treatment process: one heat treatment (HT1), the temperature is 845°C, the oxygen partial pressure is 20%, and the holding time is 250h; the oxygen partial pressure is reduced to 17.5%, and the holding time is continued for 20h, and the temperature remains unchanged.

[0050] After the above heat treatment process, the critical transition temperature (Tc) of the superconducting tape is 111.5K, and the critical current (Ic) is 135A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com