Proportional control type continuously variable transmission flow active control system

A technology of active control system and continuously variable transmission, which is applied in transmission control, components with teeth, belt/chain/gear, etc. It can solve the problems of low control efficiency, low control precision, low system working efficiency, and large energy loss. , to achieve real-time and accurate flow switching, achieve optimal matching, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

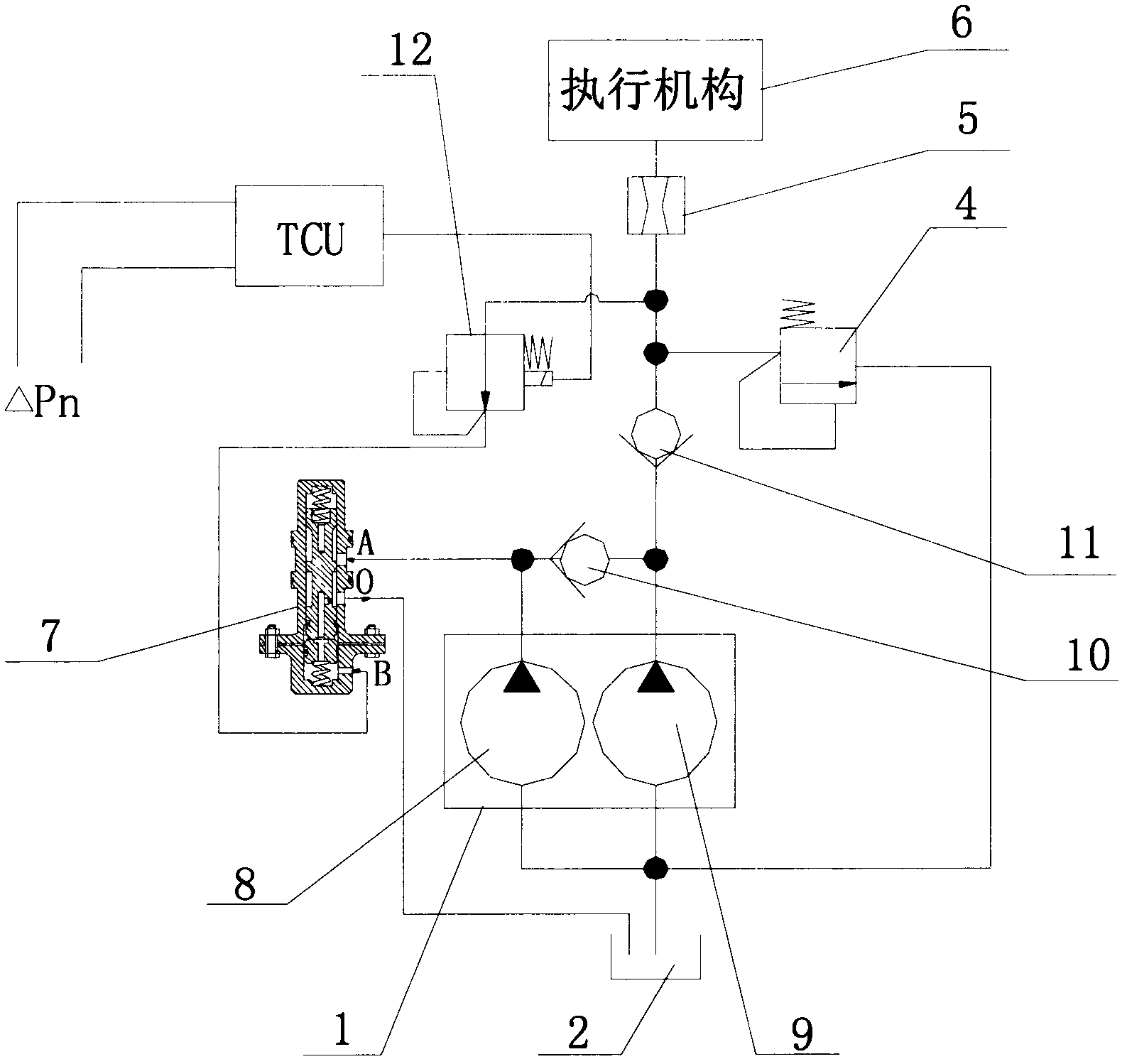

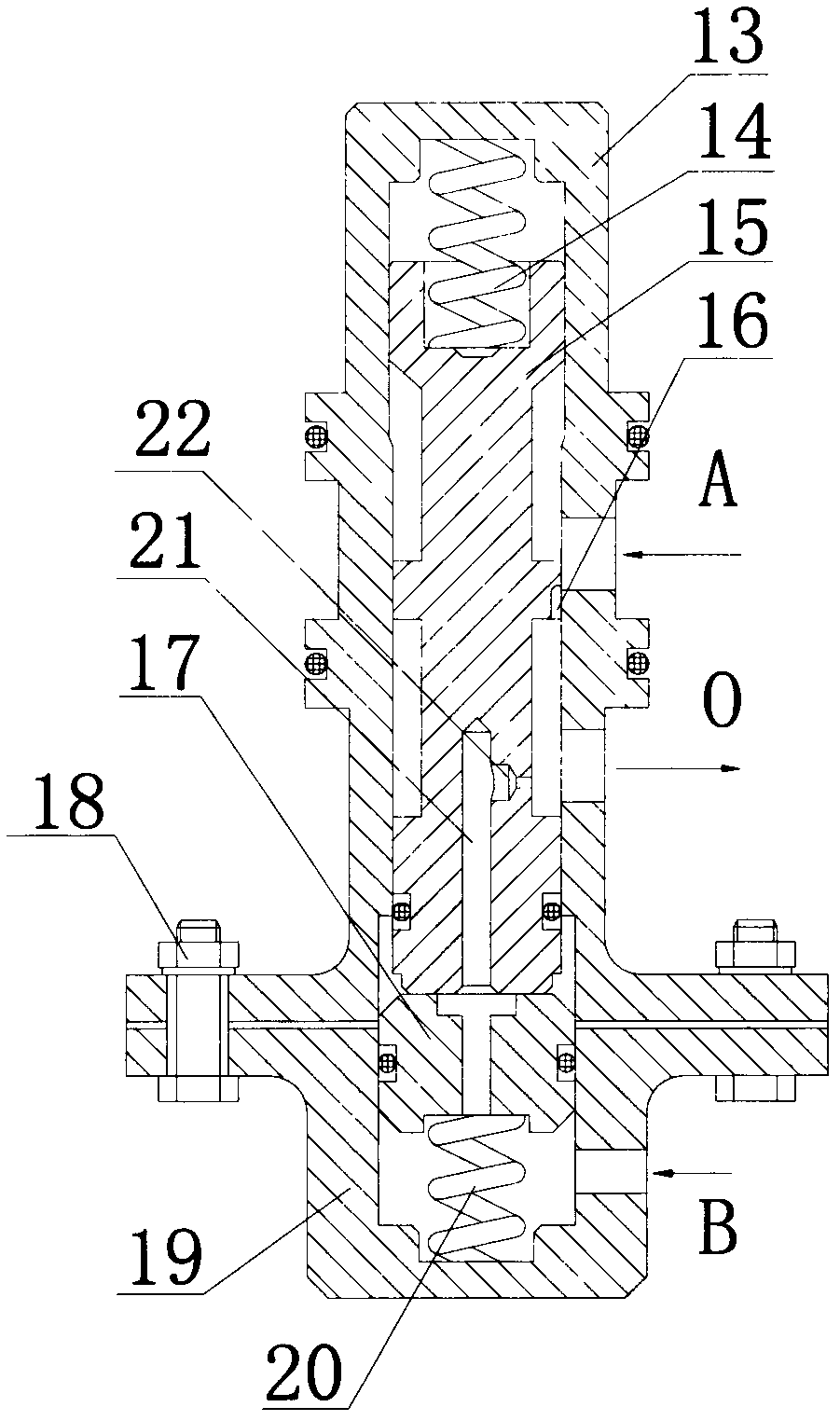

[0015] Such as figure 1 As shown, a proportional control type continuously variable transmission flow active control system includes a double hydraulic pump 1, the double hydraulic pump 1 is divided into a main pump unit 9 and an auxiliary pump unit 8, the main pump unit 9 and the auxiliary pump unit 8 The oil inlet of the pump is connected to the oil tank 2, the rotor of the double hydraulic pump 1 is connected to the hydraulic pump 3; the oil outlet of the main pump unit 9 is respectively connected to the main check valve 11 and the auxiliary check valve 10, and the main check valve 11 The other end is respectively connected to the oil inlet port of the overflow valve 4 and the throttle port 5, and the oil outlet port of the overflow valve 4 is connected to the oil tank 2; the other end of the throttle port 5 is connected to the actuator 6; the other end of the auxiliary check valve 10 Connect to the oil inlet A of the reversing valve 7; the oil outlet of the auxiliary pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com