Corrosion test device for simulating environment alternation

A technology of corrosion test and simulated environment, applied in the field of corrosion test device and controlled corrosion device, it can solve the problems of being unsuitable for stress corrosion and corrosion fatigue test, unable to control seawater environmental factors, and unable to realize environmental alternation, etc. Reliable, environmentally friendly, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

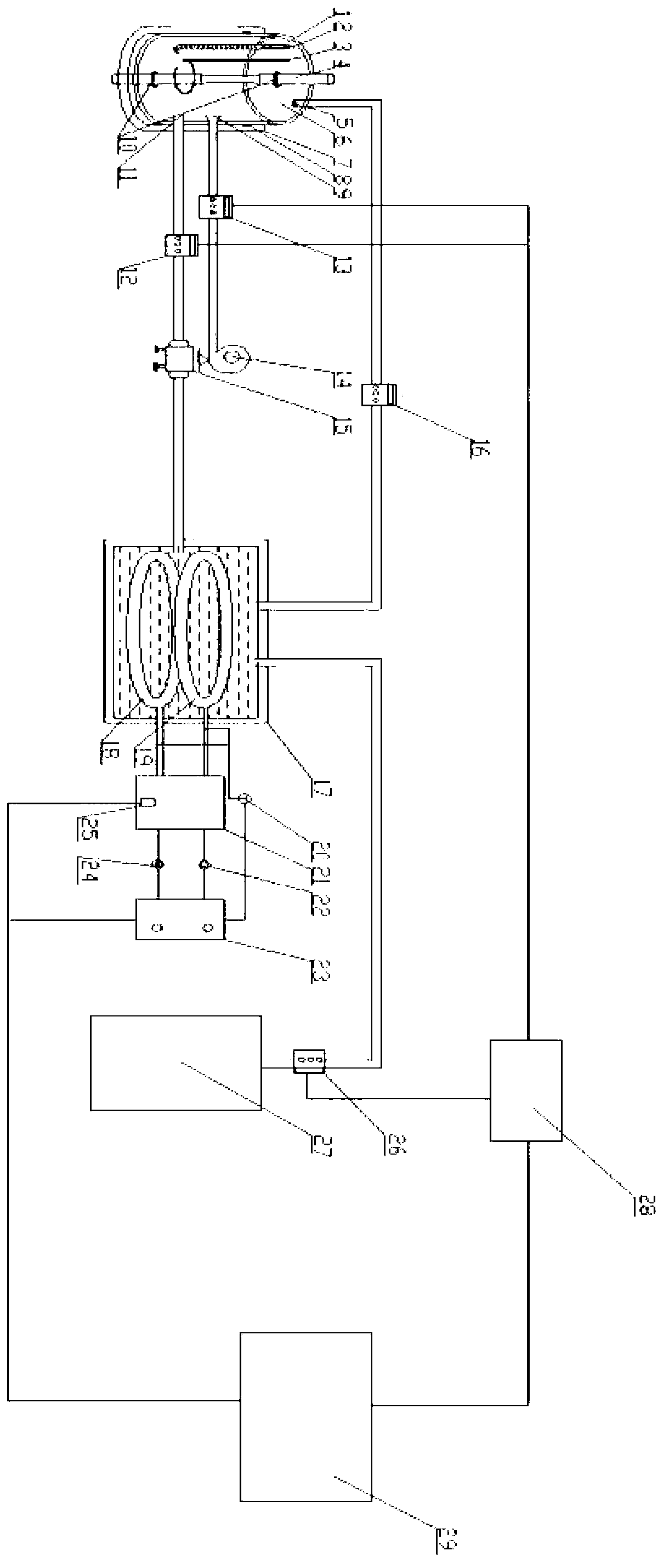

[0009] Further description will be given below through the embodiments and in conjunction with the accompanying drawings.

[0010] Example:

[0011] This embodiment is divided into three functional parts: electrolytic cell device, corrosion solution circulation system and electronic control system. The main structure includes salt bridge 1, reference electrode 2, auxiliary electrode 3, tensile sample 4, water outlet 5, and electrolytic cell upper Cylinder 6, lower cylinder of electrolytic cell 7, smooth gasket 8, air inlet 9, sealing rubber ring 10, water inlet 11, water pump inlet electronic sensor switch 12, blower electronic sensor switch 13, blower 14, water pump 15, water pump outlet Electronic induction switch 16, corrosion solution tank 17, hot water pipe 18, condensation pipe 19, temperature sensor 20, temperature controller 21, condensation device 22, temperature electronic induction switch 23, heating device 24, data acquisition device 25, environmental factor exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com