Micro-medium cone and nanometal grating-compounded optical probe

A metal grating and optical probe technology, applied in the field of optics and optoelectronics, can solve the problems of less collected light energy and small entrance of nano-metal cones, and achieve the effect of high spatial resolution and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

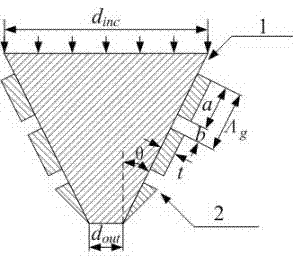

[0018] like figure 1 As shown, the optical probe with high spatial resolution and high sensitivity micro-dielectric cone and nano-metal grating compounded by the present invention is composed of micro-dielectric cone and nano-metal grating, and the refractive index of the micro-dielectric cone is n d , with a dielectric constant ε d , the large base of the micro-medium cone is the entrance of light energy, with a diameter of d inc , the small bottom surface of the micro-medium cone is the exit end of light energy, with a diameter of d out , d inc On the order of microns, d out At the nanoscale, the cone angle of the micromedia cone is 2θ. The nano-metal grating is distributed along the outer surface of the micro-medium cone, and the dielectric constant of the nano-metal grating is ε m , the period is Λ g , at the exit end of the light energy, the shape of the nanometal grating is tapered, the thickness changes linearly from t to 0, and the thickness of other parts is t. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com