Ophthalmic preparation containing lysozyme

An ophthalmic preparation and lysozyme technology, which is applied in the fields of enzymology and pharmaceutical preparation, can solve the problems of inability to store for a long time, limitation of lysozyme, poor stability of lysozyme, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

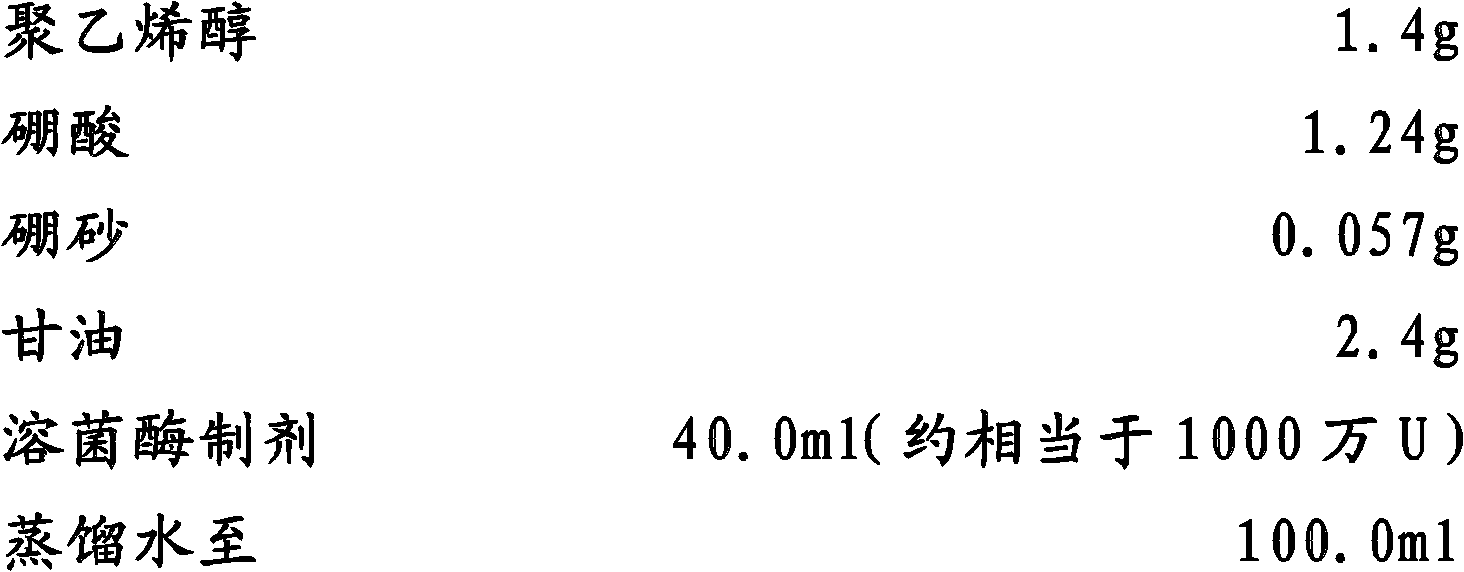

Image

Examples

Embodiment 1

[0055] Embodiment 1: the preparation of lysozyme preparation

[0056] (1) Get 0.5g of lysozyme raw material and add in 100g of water for injection, stir and dissolve, and wait for all to dissolve and set aside;

[0057] (2) Add 16 g of sodium dihydrogen phosphate thereto, and use 1mol / L sodium hydroxide to adjust the pH value of the water for injection to 5.0 ± 0.2;

[0058] (3) Stand still at 20°C for 48 hours, then filter with a mixed cellulose membrane;

[0059] (4) Add 0.02 g of activated carbon, adsorb at 70°C for 20 minutes, filter the activated carbon through a Buchner funnel, and filter the obtained solution.

[0060] (5) Put the processed solution into a low-temperature refrigerator and pre-freeze at -70°C. Usually, after 8 hours of pre-freezing, take it out and put it into a cooled cold well. The initial temperature of the cold well is between -40°C. After vacuuming for 1 hour, slowly raise the temperature to -20°C, continue vacuuming for 10 hours, and transfer to...

Embodiment 2

[0061] Embodiment 2: the preparation of lysozyme preparation

[0062] (1) Get 6.2g of boric acid, add 0.029g of borax in 100g of water for injection, stir and dissolve, and wait for all to dissolve for later use;

[0063] (2) Add 2.5g lysozyme raw material to it, make its pH value to 6.3±0.3;

[0064] (3) Refrigerate and stand at 4°C for 2 hours, then filter through a vertical melting funnel;

[0065] (4) Add 2 g of bentonite, absorb at 80° C. for 5 minutes, filter through a sand filter to remove the bentonite, and obtain the treated lysozyme preparation for future use.

Embodiment 3

[0066] Embodiment 3: the preparation of lysozyme preparation

[0067] (1) Get 4.0 g of sodium sulfate and add it to 100 g of water for injection, stir and dissolve, and wait for all to dissolve for later use;

[0068] (2) 5.0g lysozyme raw material is added thereto, and sodium hydroxide is used to adjust the pH value to 8.0±0.2;

[0069] (3) Stand at room temperature (25°C) for 6 hours, and filter with a sand filter;

[0070] (4) Add 10.0 g of activated carbon, absorb at room temperature (25°C) for 24 hours, remove the activated carbon by filtering through a sand filter, adjust the pH value to 10.8±0.3 with 10% concentrated sodium hydroxide solution, settle the lysozyme solid at isoelectric point, and collect the solid by filtration , At 30°C, vacuum-dry for 24 hours to obtain the lysozyme preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com