Landfill leachate treatment technology

A landfill leachate and treatment process technology, which is applied in the field of landfill leachate treatment process, can solve problems such as imbalance of nutrient elements, difficult treatment, and large floor area, so as to improve work efficiency, reduce treatment links, and reduce investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

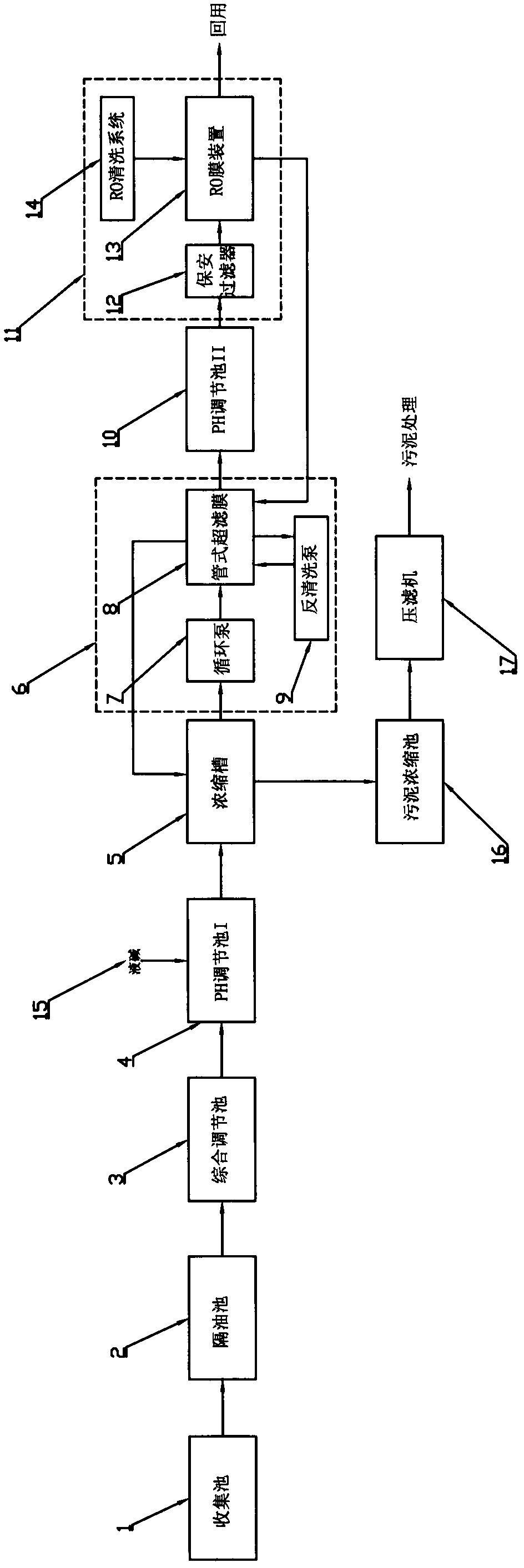

[0027] As shown in the figure, a landfill leachate treatment process, the specific treatment process is: the collection tank 1 collects wastewater, the wastewater in the collection tank 1 is introduced into the grease trap 2, the wastewater enters the grease trap 2 and stays for 30 minutes, and after degreasing The effluent enters the comprehensive adjustment tank 3, adds a small amount of air to stir the water quality, and stays for 8 hours. The effluent enters the pH adjustment tank I4 and adds liquid alkali 15 to adjust the pH value between 8.0 and 10.0. The effluent of the pH adjustment tank I4 enters the tubular ultra- Membrane filtration system 6 for filtration treatment; the concentration tank 5 receives the effluent from the previous process, and at the same time receives concentrated water that continuously flows back from the tubular ultrafiltration membrane system 6 containing suspended solids; the tubular ultrafiltration membrane system 6 is composed of a circulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com