Water-based printing ink and application thereof

A printing ink and water-based technology, applied in the field of environmentally friendly printing inks, can solve the problems that pigments are difficult to exist evenly for a long time, and the drying speed is not as good as that of oil-based inks, and achieves the effects of fast drying speed, high adhesion and good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

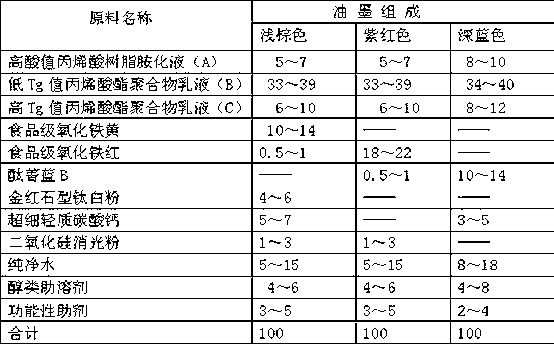

Method used

Image

Examples

Embodiment Construction

[0030] A feature of the present invention is to introduce high acid value acrylic resin amination liquid into the ink system. The high acid value acrylic resin amination solution used in the present invention is obtained by amination of high acid value acrylic resin. The high acid value here refers to the range of 140-280mgKOH / g, preferably 180-260mgKOH / g, more preferably 200-240mgKOH / g, most preferably 215-225mgKOH / g. If the acid value is too low, the resin will Poor water solubility after amination; if the acid value is too high, the coating will have poor water resistance after film formation. The average molecular weight of acrylic resin is suitable between 5000-12000. If the molecular weight is too low, the viscosity of the resin amination solution will be too low, which will cause dry film stickiness; if it is too high, the viscosity of the resin amination solution will be too high, which is not conducive to the dispersion of pigment paste . Among them, the range of 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com