Space vector object three-dimensional rotational coordinate measuring method

A technology of coordinate measurement and three-dimensional rotation, used in measuring devices, instruments, optical devices, etc., can solve the problems of single calibration method, easy to be interfered, and large measurement optical path, and achieve simple and easy installation, reasonable and simple structure. , strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

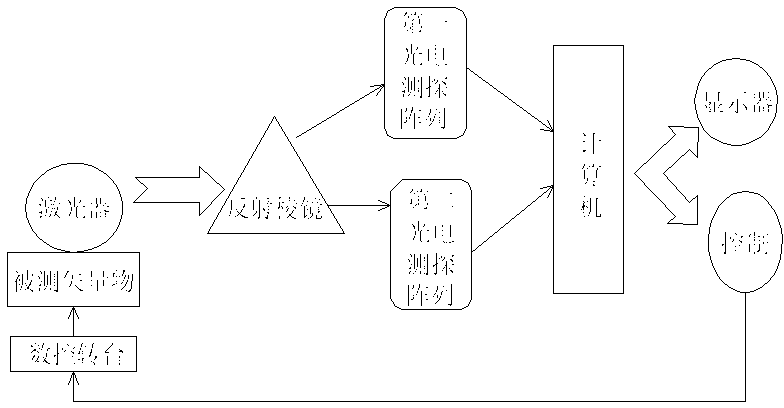

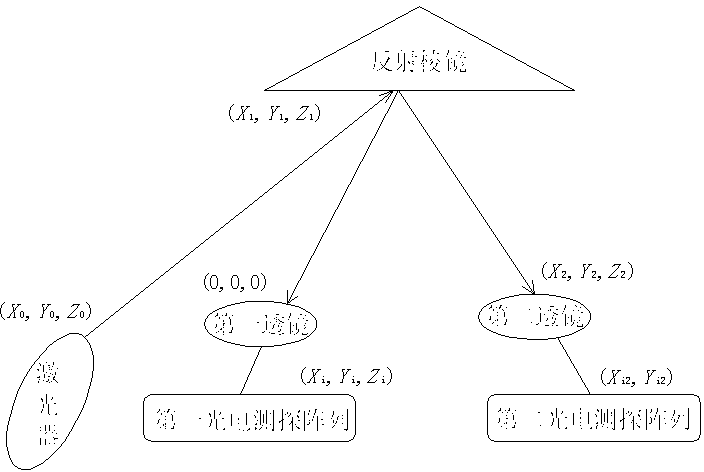

[0032] A method for measuring three-dimensional rotating coordinates of a space vector object, in which a measuring device such as figure 1 and 2 As shown, the measuring device includes a laser, a reflective prism, a first photoelectric detection array, a second photoelectric detection array, a first lens, a second lens and a computer. The computer (PC) is connected to the display and the single-chip microcomputer that controls the rotation of the CNC turntable in the three-dimensional direction, and the display is used to display the value of the rotation angle of the measured vector object.

[0033] The method for measuring three-dimensional rotating coordinates of a space vector object comprises the following steps:

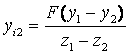

[0034] 1) Install the laser on the test point of the measured vector object, place a reflective prism on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com