Chlorine-free ink and coating compositions & a method for printing on untreated polyolefin films with improved adhesion

An untreated, composite technology, applied in the direction of ink, thin material treatment, coating, etc., can solve the problems of unfavorable chlorine-containing copolymers, toxic and recyclable chlorine-containing compounds, etc., to improve adhesion and enhance shrinkage sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

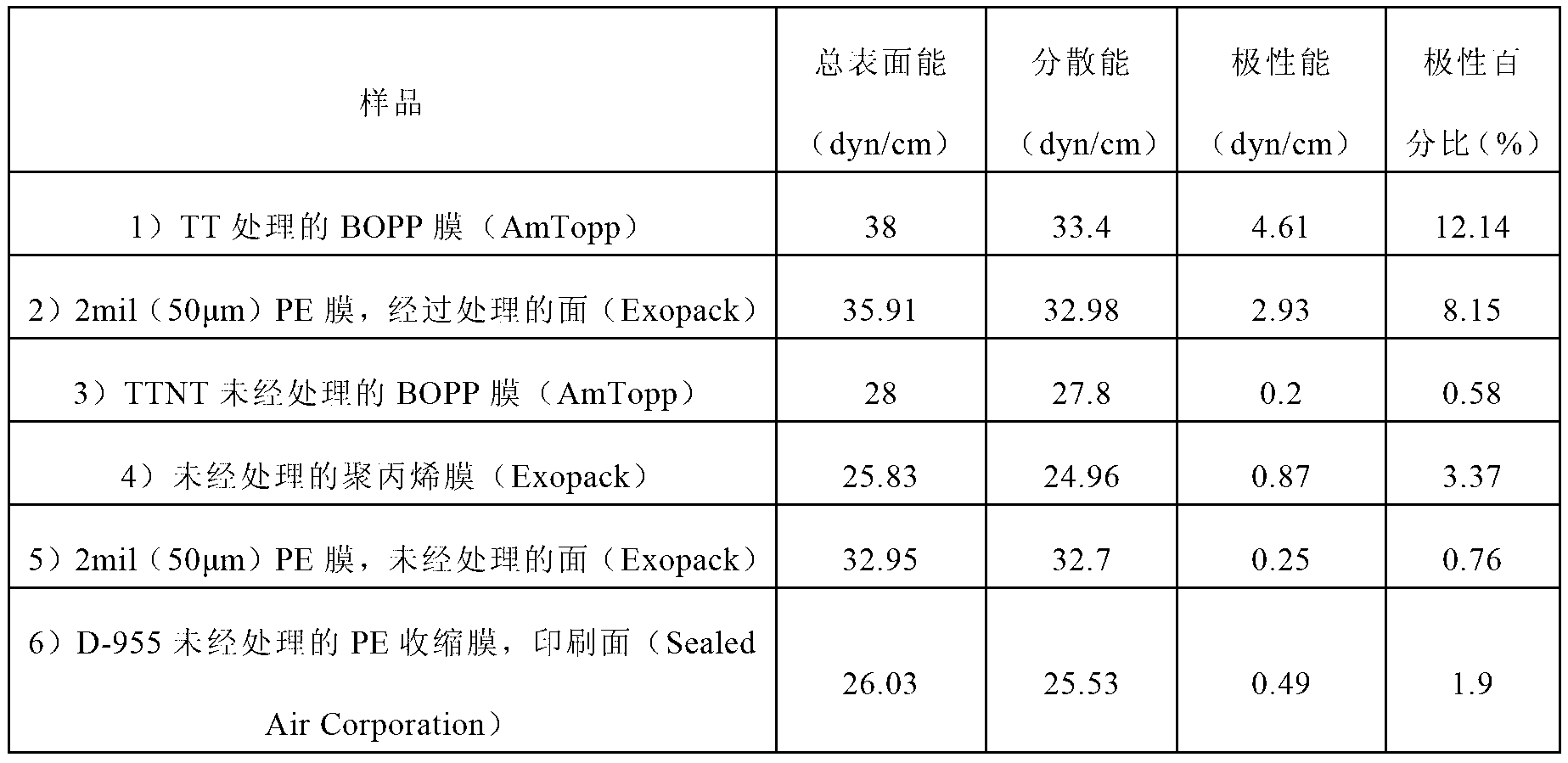

[0118] Surface energy measurement of treated and untreated polypropylene and polyethylene films

[0119] The total surface energy, the combination of dispersive and polar properties, was measured for six commercially available treated and untreated polypropylene and polyethylene films using the contact angle method. Contact angles were measured using a FIBRO DAT1100 Dynamic Absorption and Contact Angle Tester (Thwing-Albert, West Berlin, NJ) and two test liquids, namely water and diiodomethane. The measured contact angle values were used with Surface Calculator software (version 1.0; Sun Chemical, Parsippany, NJ) to calculate total surface energy, dispersion energy, and polar energy.

[0120]Two treated films were tested as well as four untreated films: 1) 25 μm thick TT-treated biaxially oriented polypropylene (BOPP) film (AmTopp, Livingston, NJ); 2) 50 μm thick (2 mil) Treated polyethylene (PE) film (Exopack, Hoffman Estates, IL); 3) 25 μm thick TTNT untreated BOPP film (...

Embodiment 2

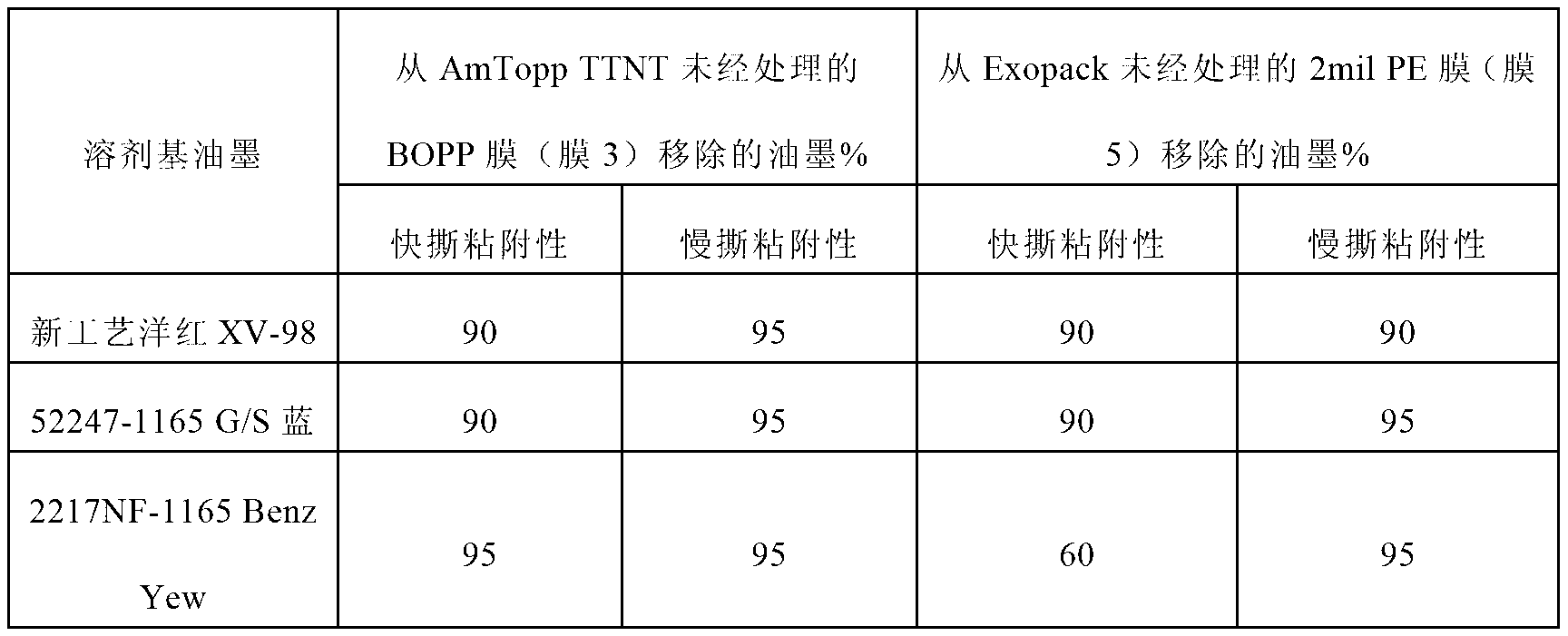

[0125] Adhesion of Commercially Available Solvent-Based Inks to Untreated Polyolefin Films

[0126] On the two untreated polyolefin films described in Example 1 (AmTopp TTNT untreated BOPP film (film 3) and the untreated side of Exopack 2mil (50 μm) PE film (film 5)), using Commercially available solvent-based ink New Craft Magenta XV-98, and polyamide pigment bases 52247-1165G / S Blue and 2217NF-1165 Benz Yew (Sun Chemical, Parsippany, NJ) were printed. Apply using a K Control Coater (RK Printcoat Instruments, Ltd., England) equipped with a standard white (wire bar number 0) meter bar (RK Printcoat Instruments, Ltd., England) ink. The film was dried in an oven at 80°C for 10 seconds.

[0127] Adhesion was measured using the adhesive tape test method. Place a strip along the length of each print Cellophane Film Tape 610 (3M, St. Paul, MN), and press twice with the thumb to ensure a tight bond between the tape and the print. Hold the print with one hand while peeling the t...

Embodiment 3

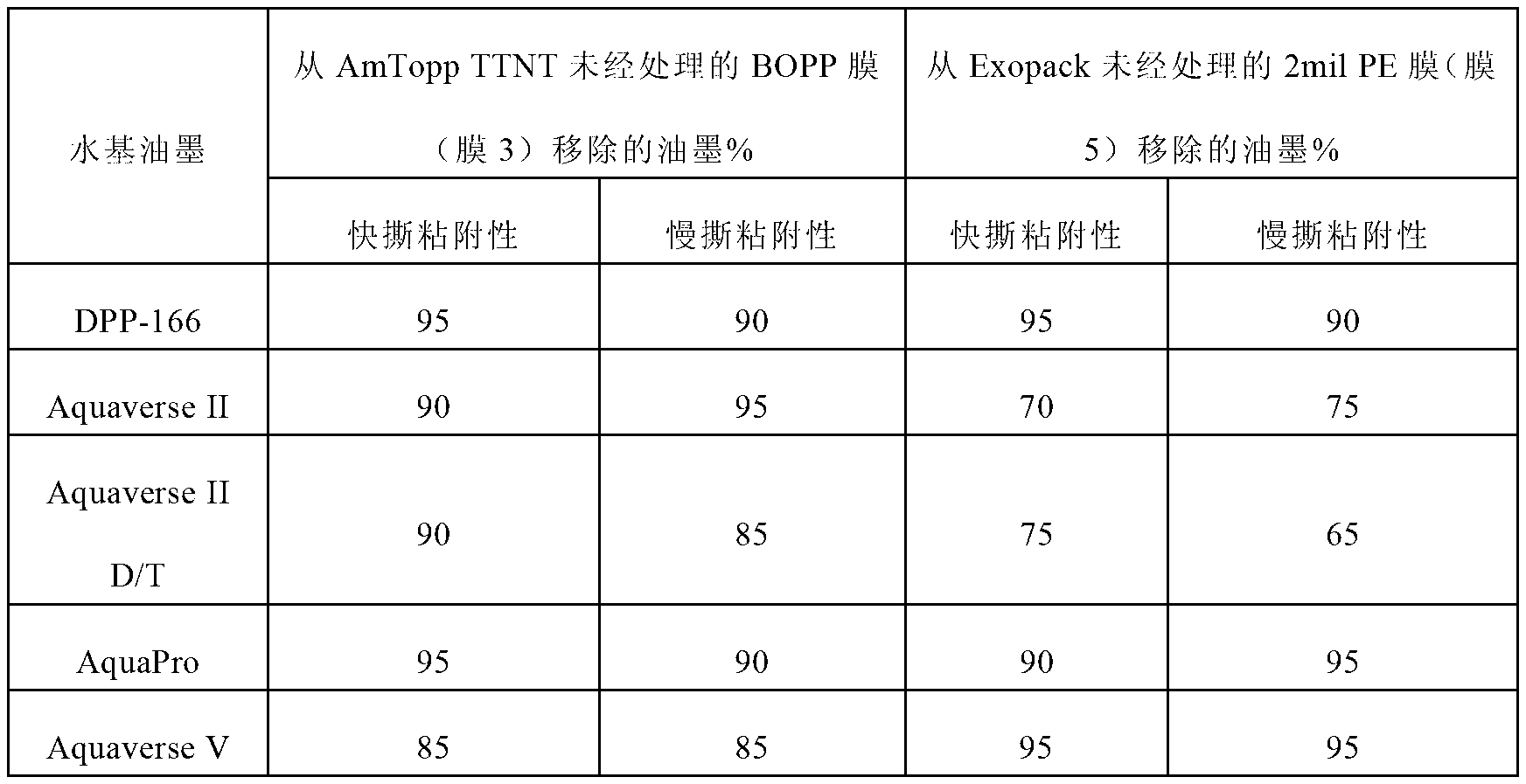

[0133] Adhesion of commercially available water-based inks to untreated polyolefin films

[0134] On the two untreated polyolefin films described in Example 1 (AmTopp TTNT untreated BOPP film (film 3) and the untreated side of Exopack 2mil (50 μm) PE film (film 5)), using Commercially available water-based inks DPP-166, Aquaverse II, Aquaverse II D / T, AquaPro, and Aquaverse V (Sun Chemical, Parsippany, NJ) were used for printing. The ink was applied using a K motor coater (RK Printcoat Instruments, Ltd., England) equipped with a standard white (wire bar number 0) metering rod (RK Printcoat Instruments, Ltd., England). The film was dried in an oven at 80°C for 10 seconds.

[0135] Adhesion was measured using the adhesive tape test method and rated as described in Example 2. Three tape tests were performed on each print at two different tape removal speeds, fast and slow. The three tests at each speed for each print were averaged to yield the percentage of ink removed from ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com