Nanometer material filter screen and preparation method thereof

A nano-material and filter screen technology, applied in the field of air purification, can solve the problems of unfairness, short effective action time, and inability to apply, and achieve the effects of convenient installation and use, shortened survival time, and practical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

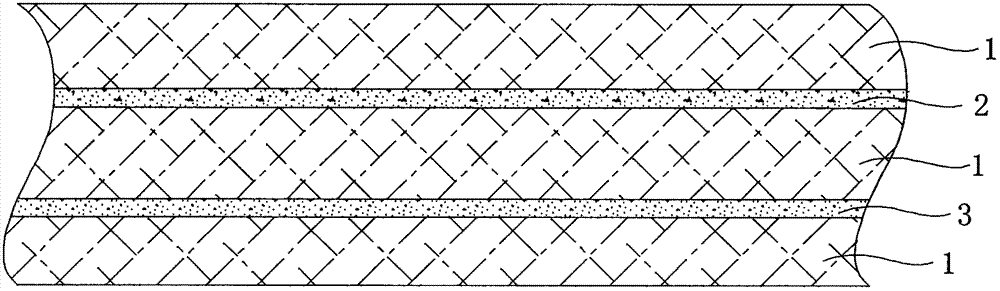

[0013] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0014] A kind of nanometer material filter net of the present invention, take felt type non-woven fabric 1 as main body, on one side of this felt type non-woven fabric 1 spray-coated with wood activated carbon powder 2, the other side of this felt type non-woven fabric 1 Nanoscale titanium dioxide powder 3 is adsorbed, and the woody activated carbon powder 2 and titanium dioxide powder 3 are respectively covered with felt-type non-woven fabric 1 and compressed to form a whole filter net. Nano-scale titanium dioxide powder is a cold catalyst, which can be decomposed to produce a hydroxyl radical (-HO) under the condition of no light or light, which has strong oxidizing and reducing properties, and can Use it as an oxidizing agent and reducing agent to isolate and kill harmful substances, harmful bacteria, etc., and shorten the survival...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com