Method for producing nano basic copper nitrate

A production method, copper nitrate technology, applied in the direction of copper nitrate, nanotechnology, nanotechnology, etc., can solve the problems of complex post-treatment process, difficult industrial production, limited specific surface area, etc., and achieve the elimination of application and promotion of defects, combustion And the effect of good catalytic performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Prepare the following reaction solutions with deionized water or double distilled water: copper nitrate aqueous solution, caustic soda solution and ammonium nitrate solution, and perform ultrafiltration treatment on the copper nitrate aqueous solution and the caustic soda solution; the mass concentration of the copper nitrate solution is 48-52%, the temperature is 25-28 ℃; the mass concentration of the caustic soda solution is 23-27%, the temperature is 25-28 ℃; the mass concentration of the ammonium nitrate solution is 1.0-1.4%, the temperature is 25- 28℃, pH value is 3.4~3.6;

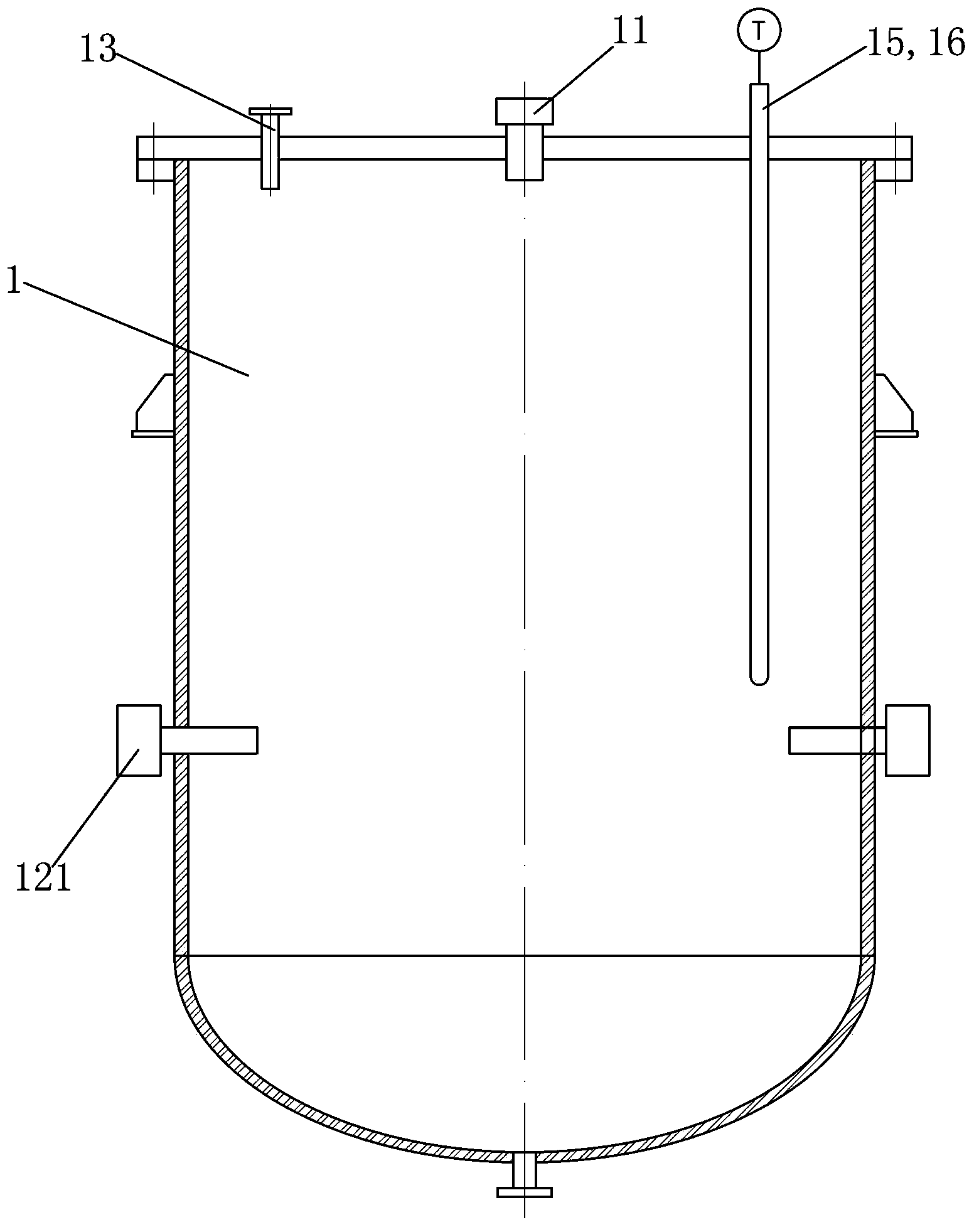

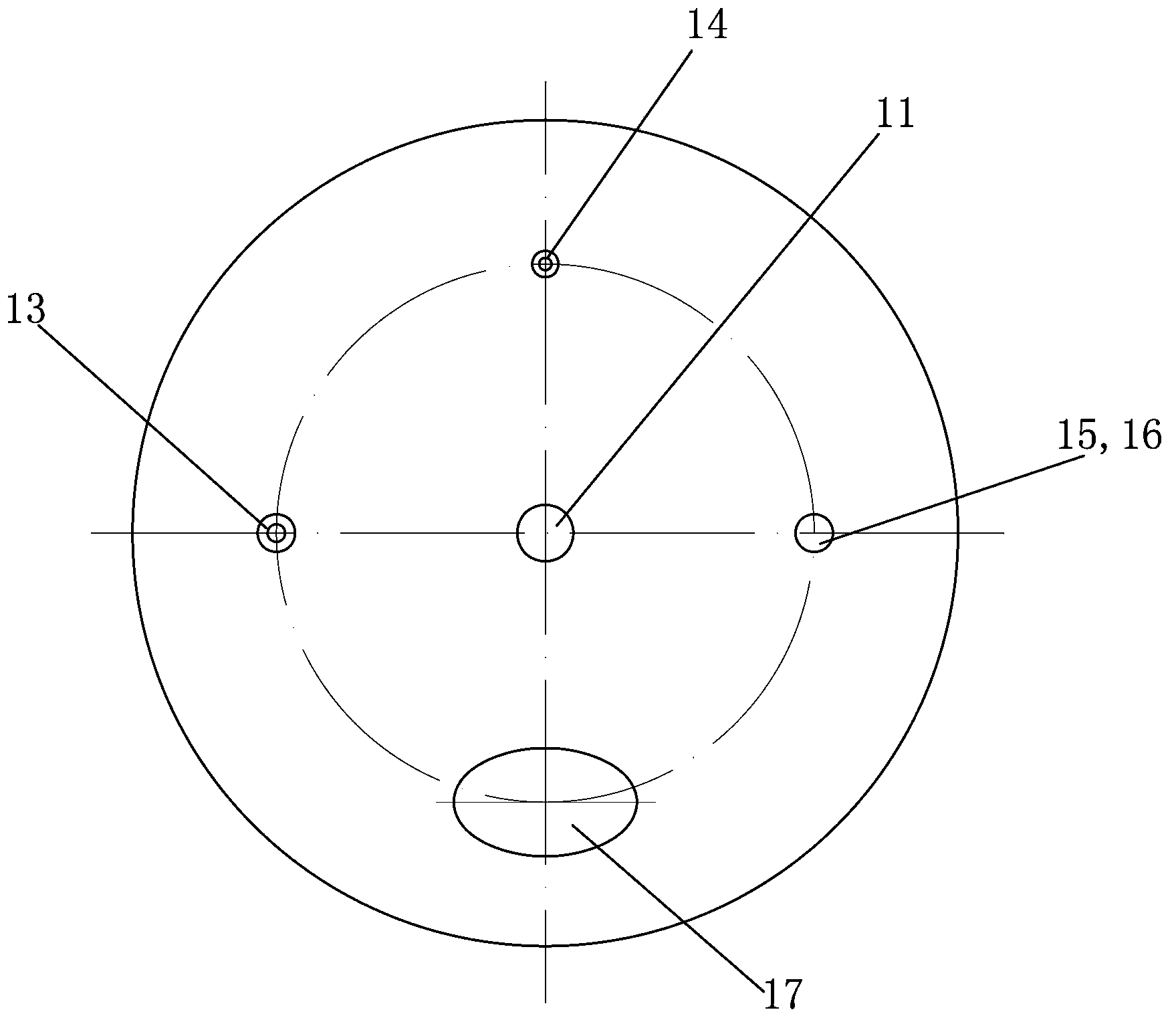

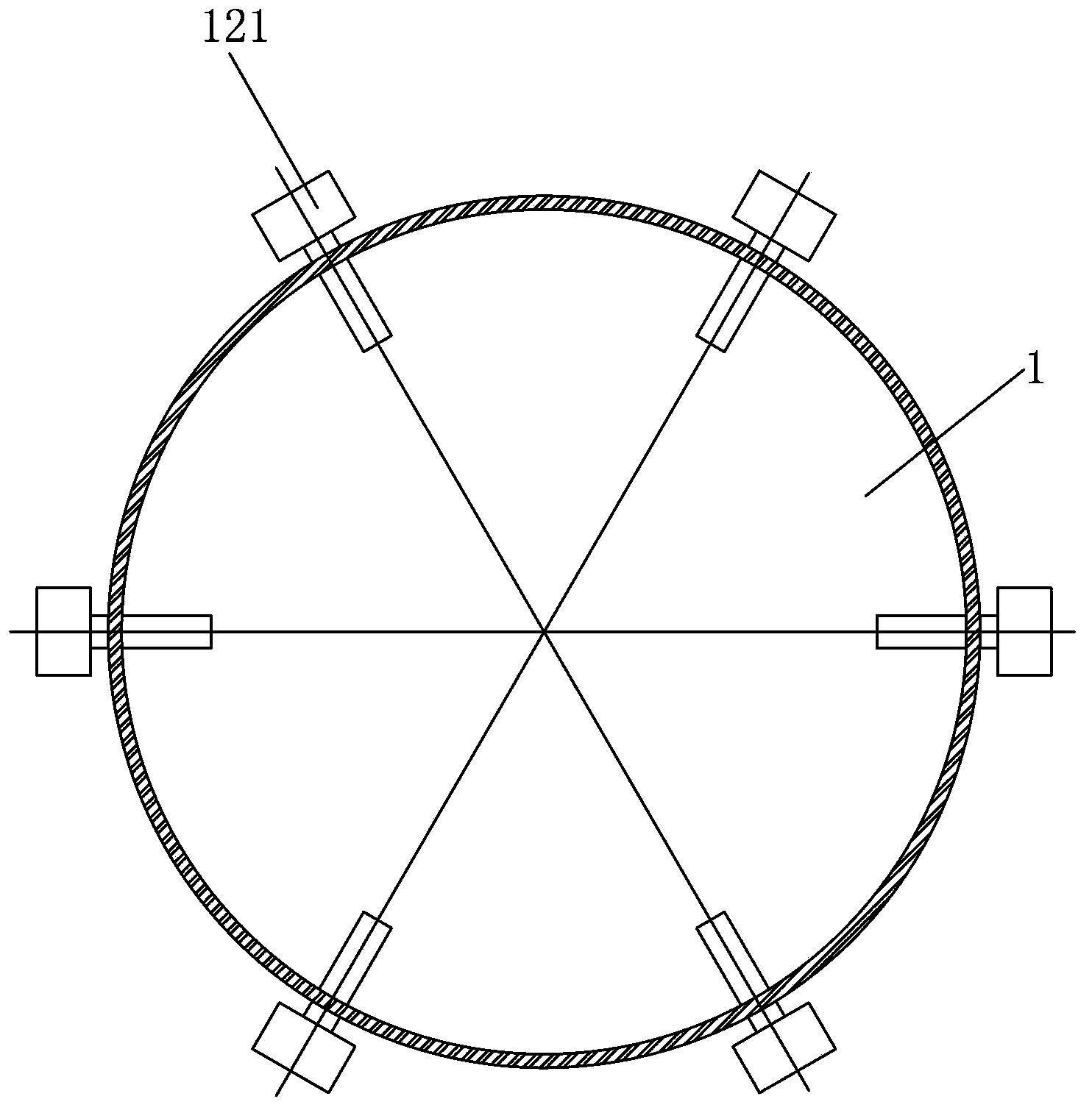

[0031] (2) Place the ammonium nitrate solution in Figure 1 to 3 In the shown reactor equipped with an ultrasonic stirring device, the copper nitrate solution after ultrafiltration and the caustic soda solution (volume ratio 1:1) are subjected to Figure 4 The shown mixed liquid high-pressure spray device is fed into the above-mentioned reactor for the reaction, that is, the feeding rate of the...

Embodiment 2

[0038] (1) Prepare the following reaction solutions with deionized water or double distilled water: strontium carbonate aqueous solution, caustic soda solution and ammonium nitrate solution, and perform ultrafiltration treatment on the strontium carbonate aqueous solution and the caustic soda solution; the mass concentration of the strontium carbonate solution is 48-52%, the temperature is 25-28 ℃; the mass concentration of the caustic soda solution is 23-27%, the temperature is 25-28 ℃; the mass concentration of the ammonium nitrate solution is 1.0-1.4%, the temperature is 25- 28℃, pH value is 3.4~3.6;

[0039] (2) Place the ammonium nitrate solution in Figure 1 to 3 In the shown reactor equipped with an ultrasonic stirring device, the ultra-filtered strontium carbonate solution and caustic soda solution (volume ratio 1:1) Figure 4 The shown mixed liquid high-pressure spray device is fed into the above-mentioned reactor for the reaction, that is, the feed rate of the strontium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com