Efficient autotrophic denitrification method of bacterial filter

A biological filter, autotrophic denitrification technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problem of small denitrification load, and achieve the effect of strong interception capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

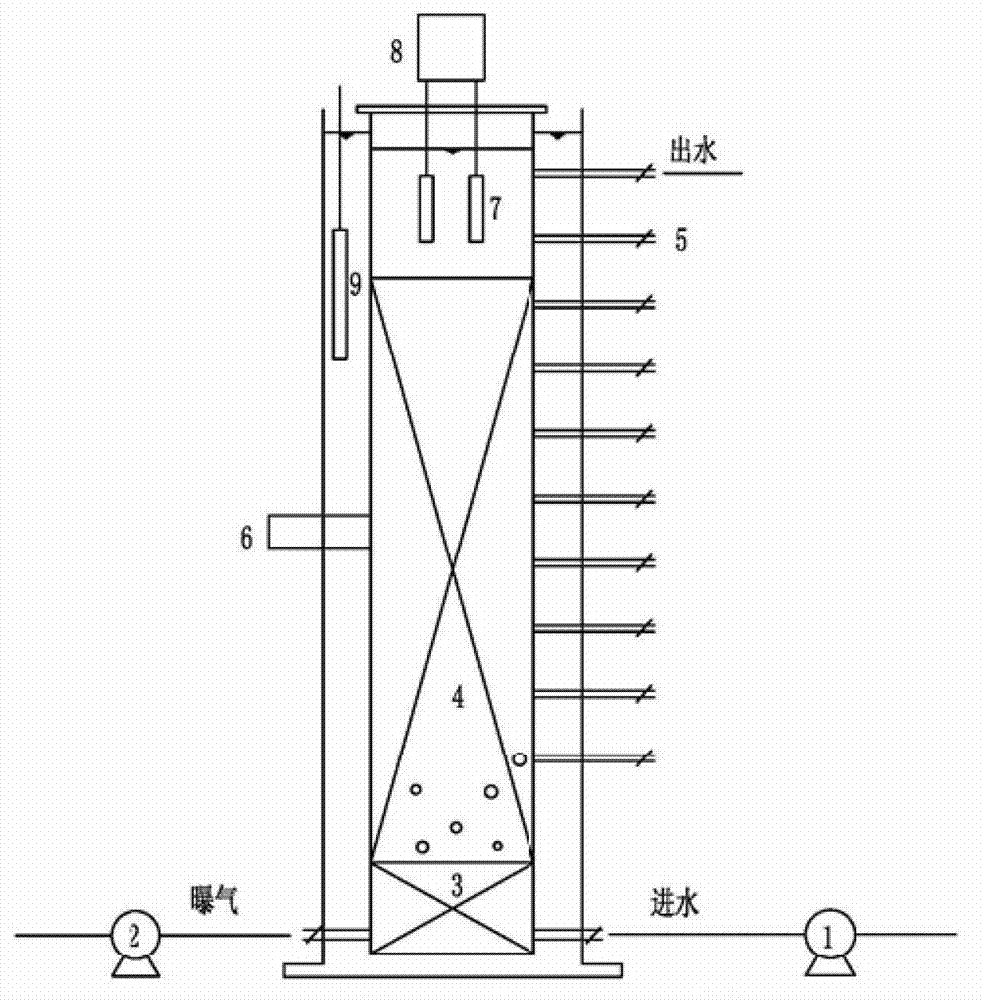

[0014] The reactor of the present invention is made of organic glass columns, with an inner diameter of 250mm, a filling height of 1300mm, a 20mm river pebble supporting layer at the bottom, a disc membrane aeration device, and a total volume of 40L in the reaction zone. In this experiment, volcanic rock is selected as the filter material, with an average porosity of 80% inside and outside, a particle size ranging from 4.0 to 6.0 mm, and an apparent density of 1.60-1.80 kg / m 3 , Bulk density 0.7-0.9kg / m 3 . The filling height of the filter material is 900mm, the filling rate of the filler is 100%, and the initial effective volume is 21L. The reactor adopts an up-flow water inlet method, raw water and aeration enter from the bottom, and the outlet water flows out from the upper water outlet. During the test, the temperature of the reactor was controlled by the heating of the water bath wrapped in the sleeve outside the reaction zone, and the aeration volume was controlled by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com