Binary copolymerized polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

A technology of binary copolymerization of polyacrylonitrile-based carbon fiber and spinning solution, which is applied in the fields of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, and can solve the complex preparation process and difficult large-scale production of raw silk And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment is a binary copolymerized polyacrylonitrile-based carbon fiber spinning solution and its preparation method.

[0023] The binary copolymerized polyacrylonitrile-based carbon fiber spinning solution uses dimethyl sulfoxide as a solvent, azobisisobutyronitrile as an initiator, and acrylonitrile and itaconic acid as polymer monomers. Acrylonitrile: the weight percent of itaconic acid is 99.0:1.0. The concentration of the polymer monomer is 20%. The consumption of azobisisobutyronitrile is 0.75% of monomer weight.

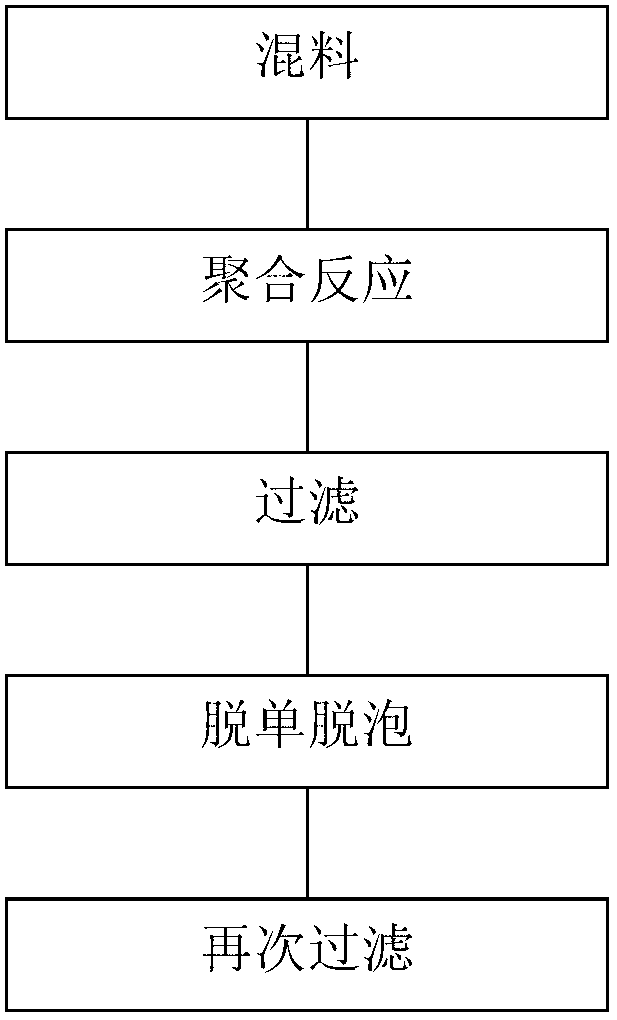

[0024] The preparation method that present embodiment proposes comprises the following steps:

[0025] Step 1, mixing ingredients. Weigh each material according to the ratio, and stir and mix the materials in the batching kettle.

[0026] Step 2, polymerization reaction. Put the prepared mixed materials into the polymerization tank, and use the conventional method to continue the polymerization reaction for 32 hours. During the polymerizati...

Embodiment 2

[0033] This embodiment is a binary copolymerized polyacrylonitrile-based carbon fiber spinning solution and its preparation method.

[0034] The binary copolymerized polyacrylonitrile-based carbon fiber spinning solution uses dimethyl sulfoxide as a solvent, azobisisobutyronitrile as an initiator, and acrylonitrile and itaconic acid as polymer monomers. Acrylonitrile: the weight percent of itaconic acid is 98.5:1.5. The monomer concentration of the polymer was 21%. The consumption of azobisisobutyronitrile is 0.75% of monomer weight.

[0035] The preparation method that present embodiment proposes comprises the following steps:

[0036] Step 1, mixing ingredients. Weigh each material according to the ratio, and stir and mix the materials in the batching kettle.

[0037] Step 2, polymerization reaction. Put the prepared mixed materials into the polymerization tank, and use the conventional method to continue the polymerization reaction for 32 hours. During the polymerizat...

Embodiment 3

[0044] This embodiment is a binary copolymerized polyacrylonitrile-based carbon fiber spinning solution and its preparation method.

[0045] The binary copolymerized polyacrylonitrile-based carbon fiber spinning solution uses dimethyl sulfoxide as a solvent, azobisisobutyronitrile as an initiator, and acrylonitrile and itaconic acid as polymer monomers. Acrylonitrile: the weight percent of itaconic acid is 99.0:1.0. The monomer concentration of the polymer was 22%. The consumption of azobisisobutyronitrile is 0.75% of monomer weight.

[0046] The preparation method that present embodiment proposes comprises the following steps:

[0047] Step 1, mixing ingredients. Weigh each material according to the ratio, and stir and mix the materials in the batching kettle.

[0048] Step 2, polymerization reaction. Put the prepared mixed materials into the polymerization tank, and use the conventional method to continue the polymerization reaction for 32 hours. During the polymerizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com