Epoxy asphalt material, as well as preparation method and use method thereof

An epoxy asphalt material and asphalt technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of builders' physical and environmental damage, high energy consumption of epoxy asphalt production, and harmful asphalt smoke to the human body, etc., to achieve Effects of improving mechanical strength and stability, excellent anti-rutting performance, and excellent low-temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The present invention provides a kind of preparation method of epoxy asphalt material described in above-mentioned technical scheme, comprises the following steps:

[0078] a) Heat the asphalt to 80℃~180℃, mix epoxy diluent, epoxy compatibilizer, aliphatic dicarboxylic acid, aliphatic dicarboxylic polyanhydride and epoxy resin curing agent with the heated asphalt , to obtain part A of the epoxy asphalt material after stirring;

[0079] b) Mix part A and part B of the epoxy asphalt material obtained in step a) at room temperature to obtain an epoxy asphalt material, the part B is epoxy resin, and the part A and part B The mass ratio is (0.5~5):1.

[0080] In the present invention, the pitch is first heated to 80°C-180°C, preferably 90°C-170°C, more preferably 100°C-160°C, most preferably 110°C-150°C; Thinner, epoxy compatibilizer, aliphatic dicarboxylic acid, aliphatic dicarboxylic polyanhydride and epoxy resin curing agent are mixed with the heated asphalt, and after ...

Embodiment 1

[0090] 100 parts by weight of CH 3 (CH 2 ) 5 CH=CH(CH 2 ) 2 CH=CH(CH 2 ) 5 CH 3 And 150 parts by weight of epoxy resin (grade E-51, Sinopec Baling Petrochemical Co., Ltd.), and 7 parts by weight of catalyst ammonium bromide were added to the reactor, and reacted at 100 ° C for 4 hours , obtained with epoxy compatibilizer.

[0091] In the present invention, the structure of the obtained epoxy compatibilizer is identified, and the results show that the epoxy compatibilizer obtained in this example has the structure shown in formula (I), wherein X1 is 5, Y1 is 2, and Z1 is 6.

Embodiment 2

[0093] 160 parts by weight of CH 3 (CH 2 ) 5 CH=CH(CH 2 ) 10 CH 3 And 200 parts by weight of epoxy resin (grade E-51, Sinopec Baling Petrochemical Co., Ltd.) and 10 parts by weight of catalyst ammonium bromide were added to the reactor, and reacted at 170 ° C for 4 hours to obtain ring Oxygen expander.

[0094] In the present invention, the structure of the obtained epoxy compatibilizer is identified, and the result shows that the epoxy compatibilizer obtained in this example has the structure shown in formula (II), wherein X2 is 5 and Y2 is 11.

PUM

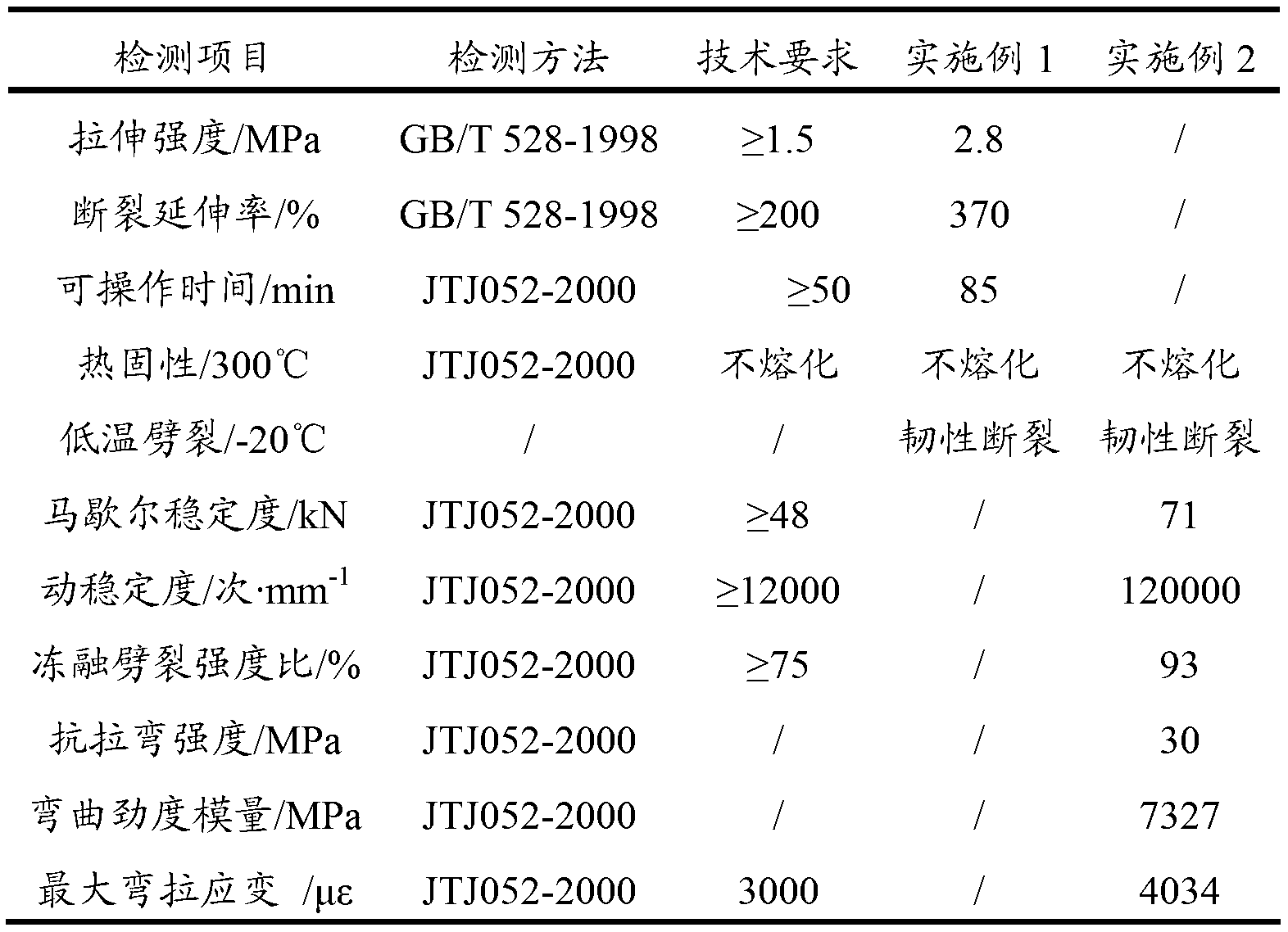

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Marshall stability | aaaaa | aaaaa |

| Marshall stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com