Blended yarns of seaweed fibers, pupa protein fibers and Levin bamboo fibers, shell fabric and production process

A technology of pupa protein fiber and seaweed fiber, which is applied in yarn, weaving, textile and papermaking, etc. It can solve the problems that blending has not yet appeared, and achieve the effect of excellent moisture absorption, air permeability and dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Spinning

[0034] (1) Spinning specification

[0035] Seaweed fiber / pupa protein fiber / bamboo fiber: 30% / 30% / 40%

[0036] Yarn density ① weaving yarn 13.1tex, ② knitting 19.5tex

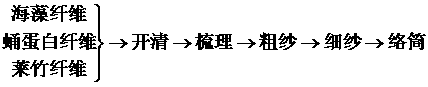

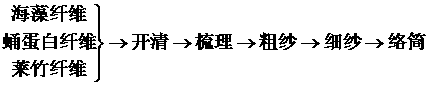

[0037] (2) Process flow

[0038] Seaweed fiber 30% + pupa protein fiber 30% + bamboo fiber 40% → opening and cleaning (including multi-compartment blending machine) → carding → drawing (first, second) → roving → spun yarn → winding

[0039] a. Open and clean cotton

[0040] Adopt soft opening and cleaning process, more combing and less beating, and the speed of each beater is controlled at 400-800r / min;

[0041] b. Carding process

[0042] The FA231A carding machine is selected, the cylinder speed is 330r / min, the licker-in speed is 680r / min, the doffer speed is 18r / min, and the 5-point distance between the cylinder and the cover plate is 0.30, 0.28, 0.28, 0.28, 0.30 (mm ), the total draft ratio is 116, and the raw sliver basis weight is 17.5g / 5m;

[0043] c. Drawing process

[0...

Embodiment 2

[0061] (1) Spinning

[0062] (1) Spinning specifications

[0063] Seaweed fiber / pupa protein fiber / bamboo fiber: 30% / 40% / 30%

[0064]Yarn density ① weaving yarn 14.8tex, ② knitting 16.7tex

[0065] (2) Process flow

[0066] The spinning process flow is the same as in Example 1.

[0067] The product of the invention has good moisture absorption and moisture permeability, soft luster, skin-friendly and nourishing skin, comfortable hand feeling, anti-radiation function and biodegradability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com