Prediction method of bearing capacity of cement-soil piles in the whole life cycle in salt water area

A full-life cycle, cement-soil pile technology, applied in construction, infrastructure testing, infrastructure engineering, etc., can solve problems such as time-consuming and labor-intensive, avoid time-consuming and labor-intensive problems, have high measurement accuracy, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The method proposed by the present invention is used to predict the life-cycle bearing capacity of salt-containing cement-soil piles in the Yellow River Delta of an expressway.

[0050] The test soil samples were taken from a highway K15+200, and the soil at 1m-1.5m was taken after cleaning the surface. The groundwater is brine at a depth of about 0.5m below the surface. The cement is 42.5 ordinary Portland cement produced by Dongyue Cement Factory, with a dosage of 17.58%. According to the "Highway Engineering Inorganic Binder Stable Material Test Regulations (JTJ057-1994)", the test piece is made, and the diameter of the test piece is 50mm. Two curing conditions were used in the experiment: curing room curing and salt water immersion curing, wherein the curing room curing simulates the underground environment above the water level, and the salt water immersion curing simulates the environment below the water level.

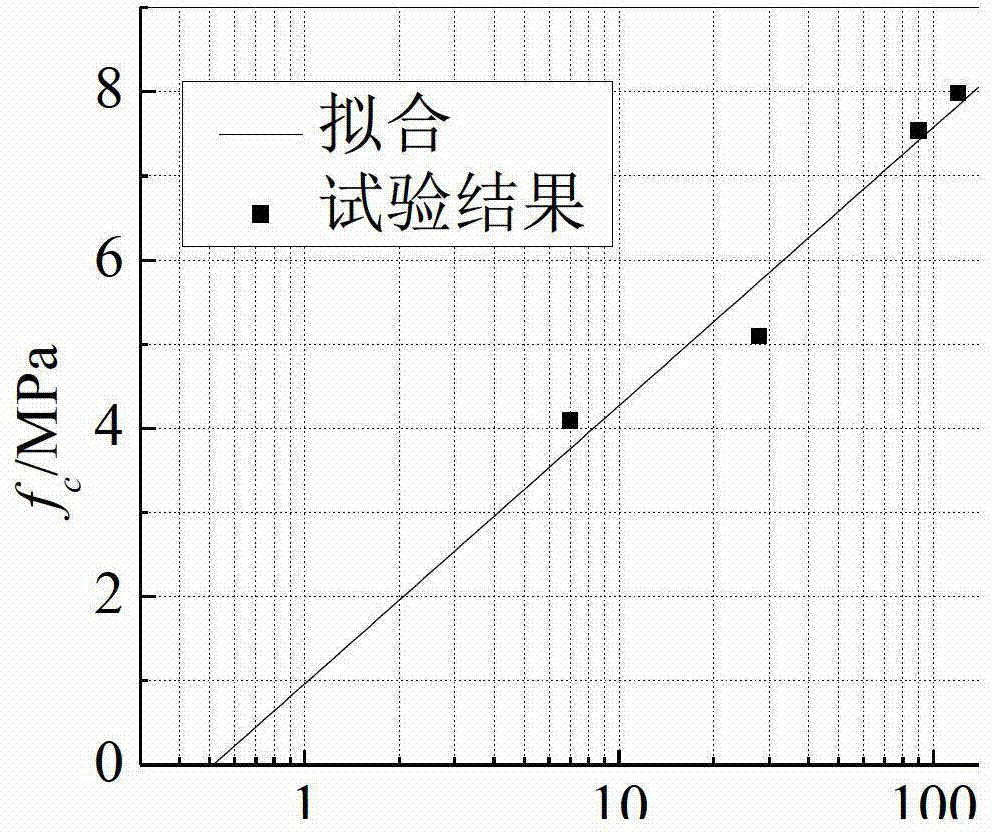

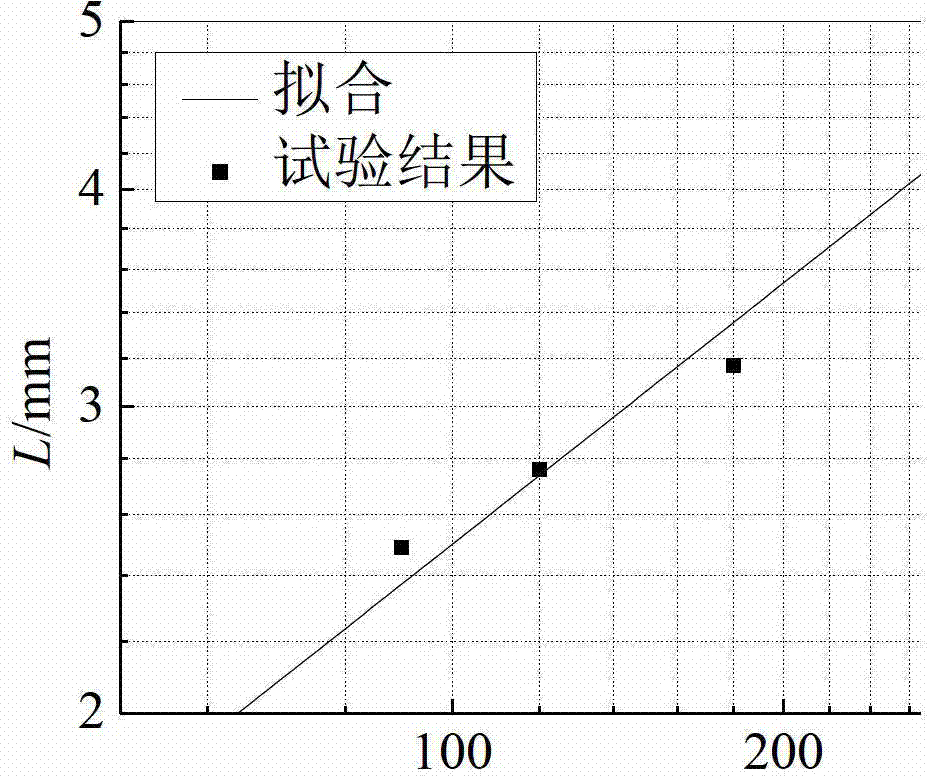

[0051] The compressive strength of saline cement ...

Embodiment 2

[0065] The method proposed by the present invention is used to predict the life-cycle bearing capacity of marine soft soil cement-soil piles in an expressway.

[0066] The test soil samples were taken from the marine soft soil of a bid section of the expressway, and the groundwater was taken from underground seawater. The cement adopts 42.5 ordinary Portland cement with a dosage of 20%. The cement soil is mechanically stirred and manually vibrated, and the diameter of the test specimen is 50mm. Two kinds of curing conditions were used in the experiment: curing room curing and seawater immersion curing, wherein the curing room curing simulates the underground environment above the water level, and the salt water immersion curing simulates the environment below the water level.

[0067] The compressive strength of saline cement soil was obtained by unconfined compressive strength test. Table 2 shows the compressive strength values of saline cement-soil specimens at different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com